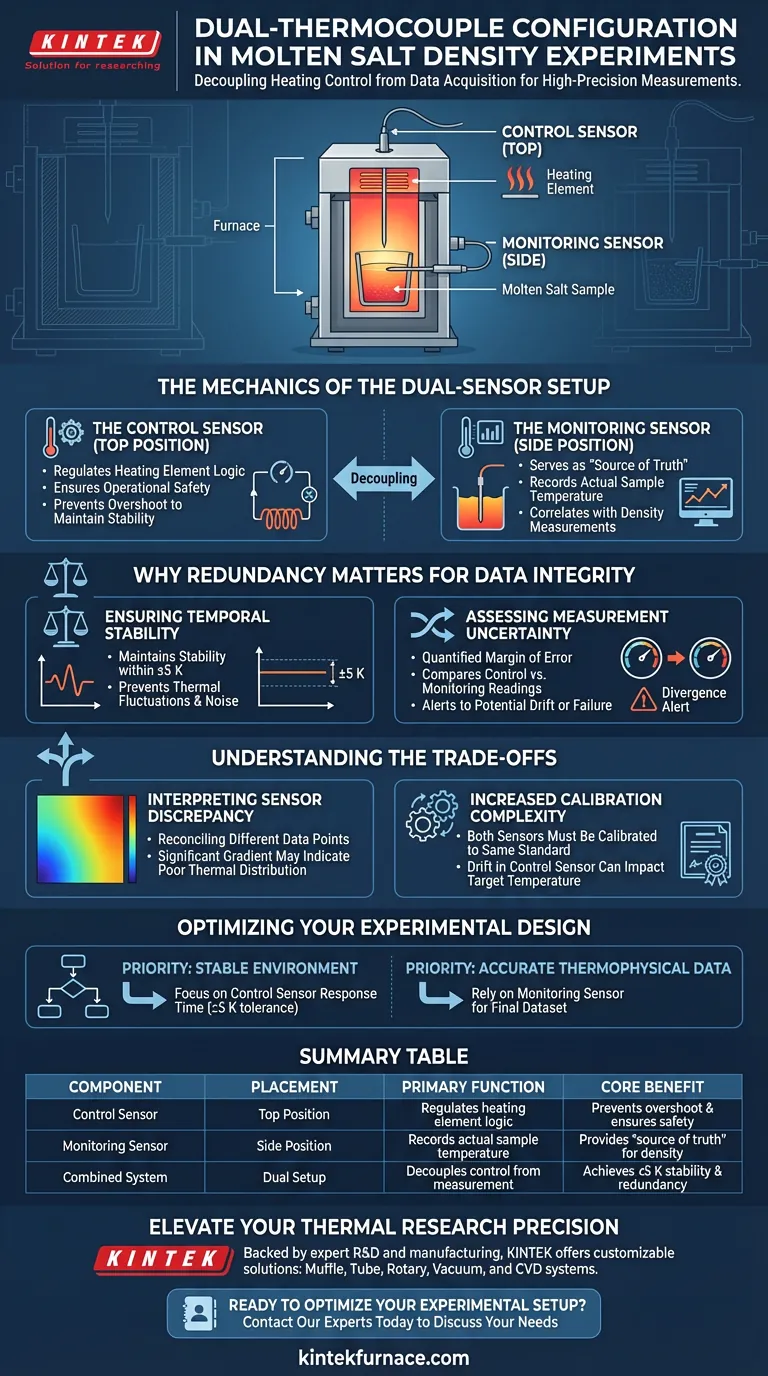

In high-precision molten salt density experiments, a dual-thermocouple configuration is essential for decoupling the heating control loop from the actual data acquisition. Specifically, one thermocouple is placed at the top of the apparatus to regulate the heating element, while a second thermocouple is positioned on the side to monitor the actual temperature of the molten sample.

By separating the control sensor from the measurement sensor, this setup ensures thermal stability within ±5 K and provides the necessary redundancy to calculate measurement uncertainty.

The Mechanics of the Dual-Sensor Setup

The Control Sensor (Top Position)

The primary function of the top-positioned thermocouple is operational safety and regulation.

It connects directly to the heating element's control logic.

Its goal is to drive the system to the setpoint without causing overshoot that could destabilize the experiment.

The Monitoring Sensor (Side Position)

The side-positioned thermocouple serves as the "source of truth" for the experiment.

It is placed closer to the sample assembly to record the actual temperature the molten salt is experiencing.

This is the data point used for correlating density measurements with specific temperatures.

Why Redundancy Matters for Data Integrity

Ensuring Temporal Stability

Molten salts require precise thermal environments to yield accurate physical property data.

The dual configuration allows the system to maintain a temperature stability of ±5 K.

This prevents thermal fluctuations from introducing noise into the density readings over time.

Assessing Measurement Uncertainty

Reliable data requires a quantified margin of error.

By comparing the readings from the control sensor (top) and the monitor sensor (side), researchers can assess measurement uncertainty.

If the divergence between the two sensors exceeds expected parameters, it alerts the operator to potential equipment drift or failure.

Understanding the Trade-offs

Interpreting Sensor Discrepancy

While redundancy improves confidence, it introduces the challenge of reconciling two different data points.

A significant temperature gradient between the top and side sensors may indicate poor thermal distribution within the furnace, rather than sensor error.

Increased Calibration Complexity

Using two sensors requires that both be calibrated to the same standard.

If the control thermocouple drifts but the monitoring thermocouple remains accurate, the system may struggle to reach the target temperature despite accurate reporting.

Optimizing Your Experimental Design

To maximize the effectiveness of a dual-thermocouple setup, align your sensor usage with your specific data requirements:

- If your primary focus is maintaining a stable environment: Prioritize the response time of the top thermocouple to ensure the heating element stays within the ±5 K tolerance.

- If your primary focus is reporting accurate thermophysical data: Rely exclusively on the side thermocouple for your final dataset, using the top sensor only for background regulation.

rigorous thermal management is the baseline requirement for producing reliable thermophysical property data.

Summary Table:

| Component | Placement | Primary Function | Core Benefit |

|---|---|---|---|

| Control Sensor | Top Position | Regulates heating element logic | Prevents overshoot & ensures safety |

| Monitoring Sensor | Side Position | Records actual sample temperature | Provides 'source of truth' for density |

| Combined System | Dual Setup | Decouples control from measurement | Achieves ±5 K stability & redundancy |

Elevate Your Thermal Research Precision

Reliable thermophysical data starts with rigorous thermal management. Backed by expert R&D and manufacturing, KINTEK offers a wide range of customizable solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are conducting molten salt experiments or advanced material synthesis, our lab high-temperature furnaces provide the stability and control your research demands.

Ready to optimize your experimental setup? Contact our experts today to discuss your unique needs

Visual Guide

References

- Jisue Moon, Theodore M. Besmann. Density Measurements of Molten LiF–BeF<sub>2</sub> and LiF–BeF<sub>2</sub>–LaF<sub>3</sub> Salt Mixtures by Neutron Radiography. DOI: 10.1021/acsomega.4c01446

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the disadvantages of MoSi2 heating elements? Key Challenges and Alternatives

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the properties of Aluminum Nitride (AlN) when used in ceramic heating elements? Achieve Precision & Safety

- What operating conditions should be avoided with MoSi2 heating elements? Prevent Premature Failure and Extend Lifespan

- How does a Silicon Carbide Heating Element generate heat? Discover high-temperature precision and durability

- How do environmental factors affect heater material selection? Choose the Right Alloy for Your Industrial Heating Needs

- What is the maximum operating temperature of a silicon carbide heating rod? Unlock High-Temp Performance Up to 1450°C

- How do Type-S thermocouples contribute to monitoring temperature fields in niobium furnaces for precise heat treatment?