MoSi2 (molybdenum disilicide) heating elements are widely used in high-temperature applications due to their ability to withstand temperatures up to 1700°C. However, they come with several disadvantages, including high initial costs, fragility, and specific operational requirements. While they offer excellent thermal performance and require minimal maintenance, their ceramic nature and electrical characteristics can pose challenges in certain industrial settings.

Key Points Explained:

-

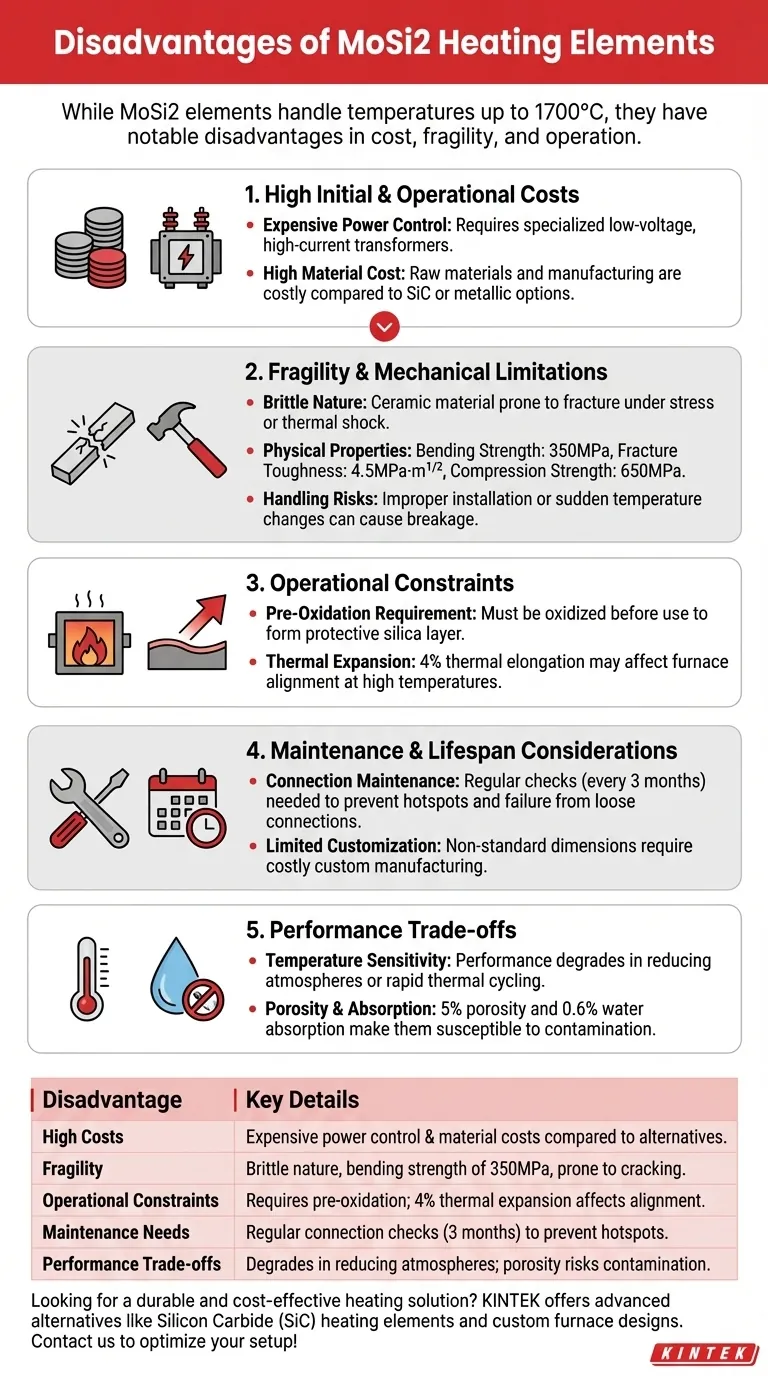

High Initial and Operational Costs

- Expensive Power Control Equipment: MoSi2 elements operate at low voltage and high startup current, necessitating specialized transformers and power control systems. This increases the initial investment compared to other high temperature heating element options.

- Material Cost: The raw materials and manufacturing process for MoSi2 elements are costly, making them more expensive than alternatives like silicon carbide (SiC) or metallic heating elements.

-

Fragility and Mechanical Limitations

- Brittle Nature: MoSi2 is a ceramic material with inherent brittleness, leading to a risk of fracture under mechanical stress or thermal shock.

- Physical Properties:

- Bending strength: 350MPa

- Fracture toughness: 4.5MPa·m¹/²

- Compression strength: 650MPa

- Handling Risks: Improper installation or sudden temperature changes can cause cracks or breakage, requiring careful handling.

-

Operational Constraints

- Pre-Oxidation Requirement: Before use, MoSi2 elements must be oxidized to form a protective silica layer that prevents further oxidation. This adds a preparatory step to the process.

- Thermal Expansion: With a thermal elongation of 4%, these elements may experience dimensional changes at high temperatures, potentially affecting furnace alignment.

-

Maintenance and Lifespan Considerations

- Connection Maintenance: Loose electrical connections can lead to hotspots and premature failure. Regular checks (every 3 months) are necessary to ensure tight connections.

- Limited Customization: While standard sizes are available (e.g., heating zone diameters from 3mm to 12mm), non-standard dimensions may require costly custom manufacturing.

-

Performance Trade-offs

- Temperature Sensitivity: Although MoSi2 elements excel in high-temperature environments (1600°C–1700°C), their performance can degrade if exposed to reducing atmospheres or rapid thermal cycling.

- Porosity and Absorption: With 5% porosity and 0.6% water absorption, these elements may be susceptible to contamination in humid or corrosive environments.

Despite these drawbacks, MoSi2 remains a preferred choice for certain high-temperature applications due to its oxidation resistance and longevity. However, purchasers must weigh these disadvantages against operational needs and budget constraints. Have you considered how these factors might impact your specific furnace setup?

Summary Table:

| Disadvantage | Key Details |

|---|---|

| High Costs | Expensive power control equipment and material costs compared to alternatives. |

| Fragility | Brittle nature with bending strength of 350MPa; prone to cracking under stress. |

| Operational Constraints | Requires pre-oxidation; thermal expansion (4%) may affect furnace alignment. |

| Maintenance Needs | Regular connection checks (every 3 months) to prevent hotspots and failure. |

| Performance Trade-offs | Degrades in reducing atmospheres; porosity (5%) risks contamination. |

Looking for a more durable and cost-effective heating solution? KINTEK offers advanced alternatives like silicon carbide (SiC) heating elements and custom furnace designs tailored to your high-temperature needs. Our in-house R&D and manufacturing ensure precision and reliability, whether you need standard or fully customized systems. Contact us today to optimize your lab or industrial furnace setup!

Products You Might Be Looking For:

High-performance vacuum valves for furnace systems

Premium observation windows for vacuum environments

Robust silicon carbide heating elements

Advanced PECVD tube furnaces for precise deposition

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C