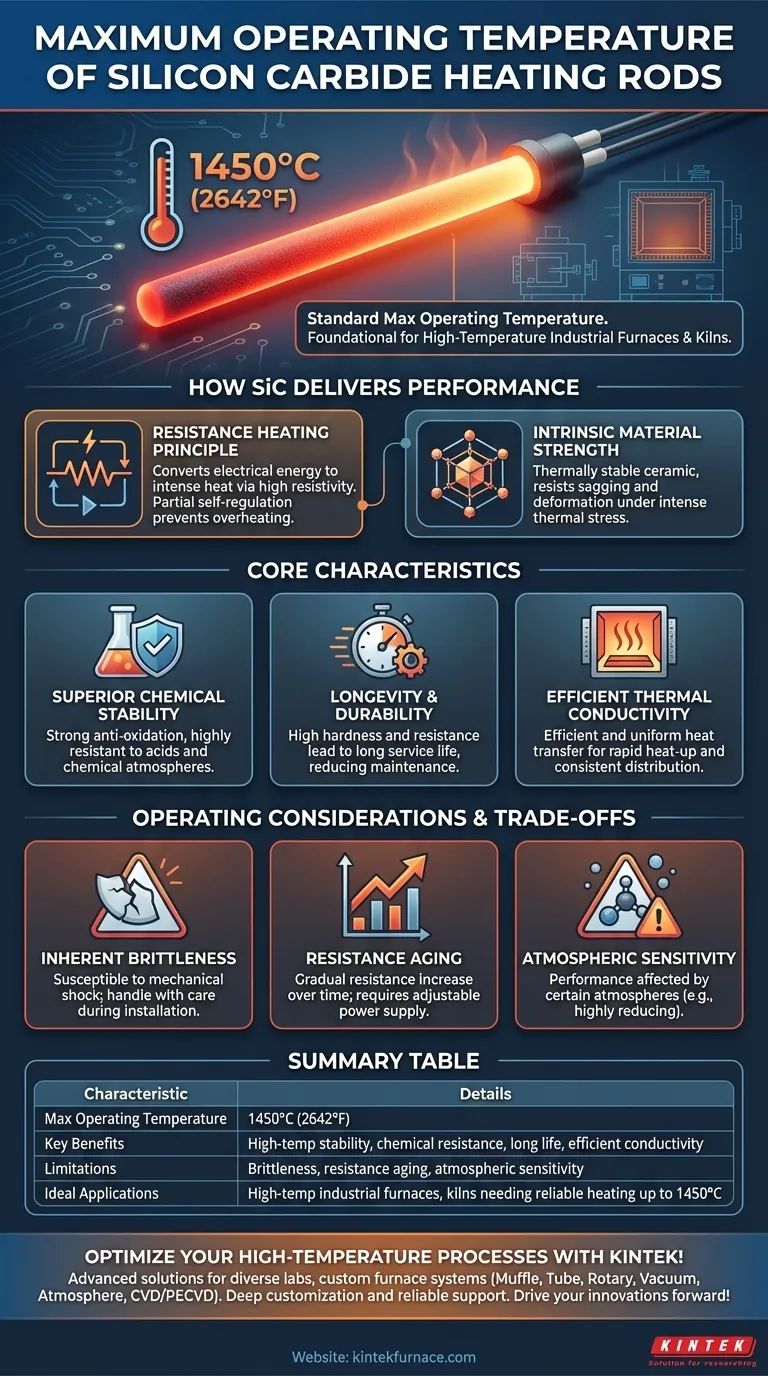

The maximum operating temperature for a standard silicon carbide (SiC) heating rod is 1450°C (2642°F). This high thermal tolerance, combined with its robust physical and chemical properties, makes it a foundational component for a wide range of high-temperature industrial furnaces and kilns.

While the 1450°C limit is its defining feature, the true value of a silicon carbide element comes from its unique combination of high-temperature stability, chemical resilience, and efficient thermal conductivity. Understanding these interconnected properties is the key to leveraging it effectively.

How Silicon Carbide Delivers High-Temperature Performance

The ability of a SiC rod to function reliably at extreme temperatures is not accidental; it is a direct result of its material science and physical principles.

The Principle of Resistance Heating

A silicon carbide rod operates by converting electrical energy into thermal energy. Due to the material's high electrical resistivity, it generates intense heat when a current is passed through it.

The material's resistivity also changes with temperature. This characteristic allows the rod to partially self-regulate its power output, contributing to a stable and consistent heating effect within the furnace.

Intrinsic Material Strength

Silicon carbide is an exceptionally hard and thermally stable ceramic. This inherent durability allows it to maintain its structural integrity under the intense thermal stress of high-temperature operation, resisting sagging or deformation.

Core Characteristics of SiC Heating Elements

Beyond its temperature ceiling, several other characteristics make SiC a preferred choice for demanding applications.

Superior Chemical Stability

SiC rods exhibit strong anti-oxidation properties and are highly resistant to acids. This chemical inertness allows them to operate reliably in various furnace atmospheres without rapid degradation.

Longevity and Durability

The combination of high hardness, thermal stability, and chemical resistance results in a long service life. This reduces the frequency of element replacement, minimizing downtime and maintenance costs over the lifetime of the equipment.

Efficient Thermal Conductivity

The material possesses good thermal conductivity. This ensures that the heat generated within the rod is transferred efficiently and uniformly to the furnace chamber, enabling rapid heat-up times and consistent temperature distribution.

Understanding the Trade-offs and Operating Considerations

No material is without its limitations. To properly engineer a system with SiC elements, you must account for their specific operational characteristics.

Inherent Brittleness

Like most ceramics, silicon carbide is brittle. The heating elements must be handled with care during installation and are susceptible to damage from mechanical shock or impact.

Resistance Aging

Over their operational life, SiC elements experience a gradual increase in electrical resistance. This phenomenon, known as aging, is a critical design consideration.

Power supply systems, often using multi-tap transformers, must be designed to supply progressively higher voltage to the elements over time to maintain constant power output and furnace temperature.

Atmospheric Sensitivity

While highly stable, performance and lifespan can be affected by certain furnace atmospheres. Highly reducing atmospheres, for example, can be more aggressive to the element's protective oxide layer than an air atmosphere, potentially shortening its life.

Making the Right Choice for Your Application

Selecting a heating element requires matching its properties to your specific process goals.

- If your primary focus is reaching process temperatures up to 1450°C with high reliability: Silicon carbide is an industry-standard choice proven for its stability and long service life.

- If your furnace design involves frequent thermal cycling: The system must be engineered to manage the thermal stresses on the brittle SiC elements to prevent fracture.

- If your budget requires minimizing long-term operational costs: The initial power supply must be specified to accommodate the age-related resistance increase to maximize the element's lifespan.

- If you require operating temperatures significantly above 1450°C: You must investigate alternative materials, such as molybdenum disilicide (MoSi2) elements, which can operate at higher temperatures.

By understanding these properties, you can confidently specify and operate silicon carbide elements for consistent and efficient high-temperature processes.

Summary Table:

| Characteristic | Details |

|---|---|

| Max Operating Temperature | 1450°C (2642°F) |

| Key Benefits | High-temperature stability, chemical resistance, long service life, efficient thermal conductivity |

| Limitations | Brittleness, resistance aging, sensitivity to certain atmospheres |

| Ideal Applications | High-temperature industrial furnaces, kilns requiring reliable heating up to 1450°C |

Optimize your high-temperature processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable silicon carbide heating elements and custom furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and durability. Contact us today to discuss how we can support your specific requirements and drive your innovations forward!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element