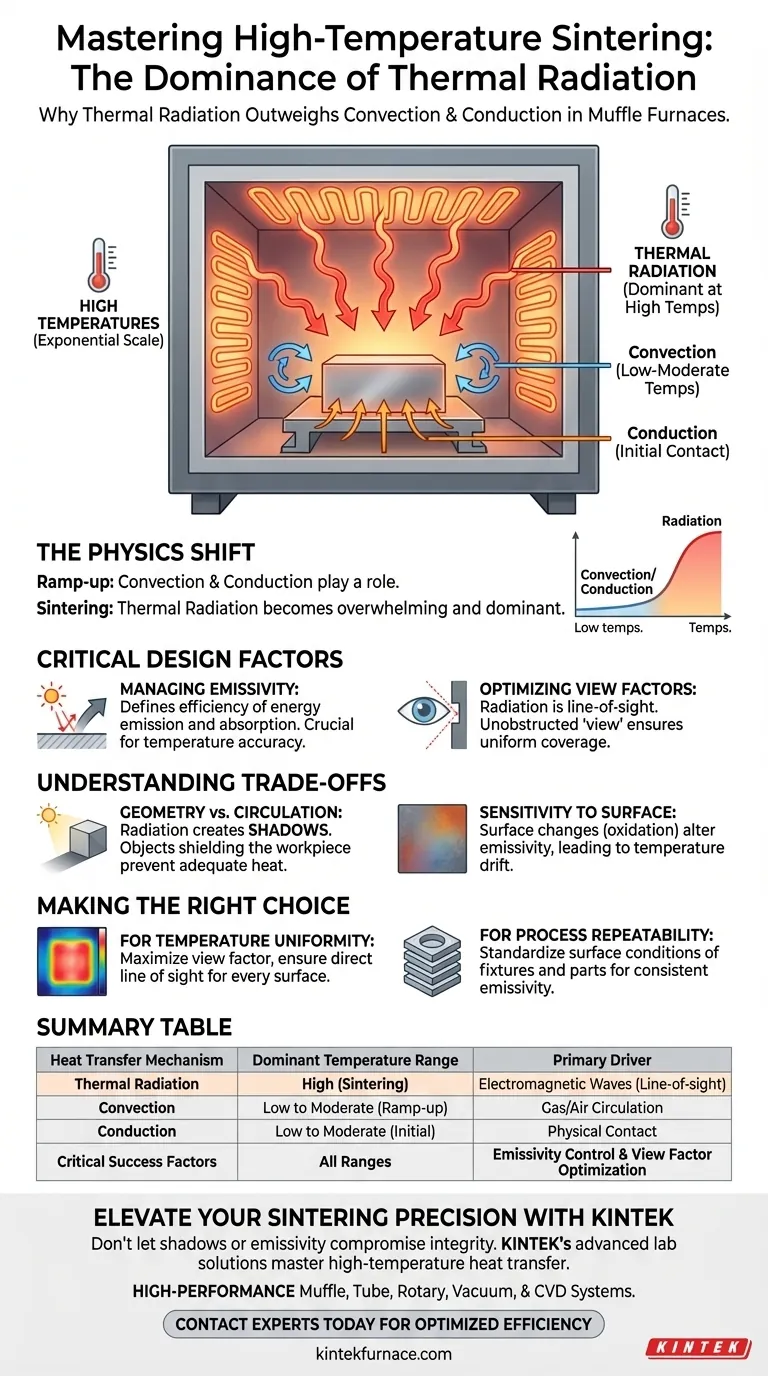

Thermal radiation is the dominant force in high-temperature sintering, far outweighing the effects of convection or conduction. While the latter two mechanisms play a role during lower-temperature ramp-up phases, thermal radiation becomes the primary driver of energy transfer once the furnace reaches sintering temperatures. Consequently, the quality of your process depends almost entirely on how well your system manages radiant energy exchange.

In high-temperature sintering environments, thermal radiation surpasses conduction and convection as the dominant energy transfer mode. Achieving temperature uniformity and process precision relies heavily on managing radiant energy through surface emissivity and furnace geometry.

The Physics of High-Temperature Heat Transfer

The Shift to Radiant Dominance

In low-temperature environments, heat transfer relies heavily on the physical movement of air (convection) or direct contact (conduction). However, as temperatures rise, the physics of heat transfer shift dramatically.

Thermal radiation becomes the overwhelming mode of energy exchange in high-temperature sintering. This is because radiant heat transfer scales exponentially with temperature, rendering convection and conduction statistically insignificant by comparison in this phase.

The Requirement for Uniform Coverage

Because radiation dominates, the transfer of energy occurs directly from the heating source to the target object.

To achieve high-precision temperature control, the radiant energy from the heating tubes must cover the workpiece surface uniformly. If the radiant field is uneven, the sintering process will be inconsistent, leading to potential structural defects in the final product.

Critical Design Factors

Managing Emissivity

To control this powerful energy transfer, you must account for emissivity. This property defines how efficiently the heating elements emit energy and how well the workpiece absorbs it.

If the emissivity values of the furnace components or the workload are not understood, the actual temperature of the part may deviate from the furnace setpoint.

Optimizing View Factors

Radiant heat transfer is strictly line-of-sight. This geometric relationship is known in engineering as the view factor.

Furnace design must ensure that the heating tubes have an unobstructed "view" of the workpiece. Proper calculation of view factors ensures that energy is distributed evenly across the entire surface area of the part.

Understanding the Trade-offs

Geometry vs. Circulation

The dominance of radiation simplifies the need for gas circulation (convection) but complicates the physical layout of the furnace.

Unlike convection, which can carry heat around corners via airflow, radiation creates shadows. If a workpiece is physically shielded from the heating elements by another object or a fixture, it will not receive adequate heat.

Sensitivity to Surface Conditions

Reliance on radiation makes the process sensitive to surface properties. Changes in the surface finish or oxidation state of the heating elements can alter their emissivity.

This can lead to drift in temperature precision over time, requiring recalibration or maintenance that would not be necessary in a purely conduction-based system.

Making the Right Choice for Your Goal

To optimize your sintering process, you must design your fixtures and furnace loading patterns around the principles of light and shadow, rather than air flow.

- If your primary focus is Temperature Uniformity: Ensure your furnace design maximizes the view factor, giving every surface of the workpiece a direct line of sight to the heating elements.

- If your primary focus is Process Repeatability: Standardize the surface condition of your fixtures and parts to maintain consistent emissivity values batch after batch.

Mastering the geometry of radiation is the key to unlocking precision in high-temperature sintering.

Summary Table:

| Heat Transfer Mechanism | Dominant Temperature Range | Primary Driver of Energy Exchange |

|---|---|---|

| Thermal Radiation | High (Sintering Phases) | Electromagnetic waves (Line-of-sight) |

| Convection | Low to Moderate (Ramp-up) | Gas or air circulation |

| Conduction | Low to Moderate (Initial contact) | Physical contact between surfaces |

| Critical Success Factors | All Ranges | Emissivity control & View factor optimization |

Elevate Your Sintering Precision with KINTEK

Don't let radiant shadows or emissivity drift compromise your material integrity. KINTEK’s advanced lab solutions are engineered to master the complexities of high-temperature heat transfer. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific thermal processing requirements.

Ready to achieve ultimate temperature uniformity? Contact our technical experts today to discover how our high-temperature furnace systems can optimize your laboratory’s efficiency and process repeatability.

Visual Guide

References

- Yuchen Wang, Haisheng Fang. Research and optimization of temperature uniformity of high-precision muffle furnace. DOI: 10.1088/1742-6596/3009/1/012076

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What optional systems are available for Box Furnaces? Enhance Your Thermal Process with Custom Solutions

- How does muffle furnace temperature precision affect thermoelectric alloys? Ensure Homogeneity in Every Ingot

- Why is a box muffle furnace used for the 800°C annealing of titanium LMD samples? Optimize Your Material Performance

- How does the airflow and temperature distribution differ between drying ovens and muffle furnaces? Key Insights for Lab Efficiency

- What is a box type resistance furnace and what is it used for? Discover Precision Heating Solutions

- What optional features are available for box furnaces? Customize for Your Lab's Unique Needs

- What is the primary function of a high-temperature box resistance furnace? Synthesizing Lithium Disilicate Ceramics

- How does a muffle furnace ensure contamination-free heating? Discover Its Isolation Design for Purity