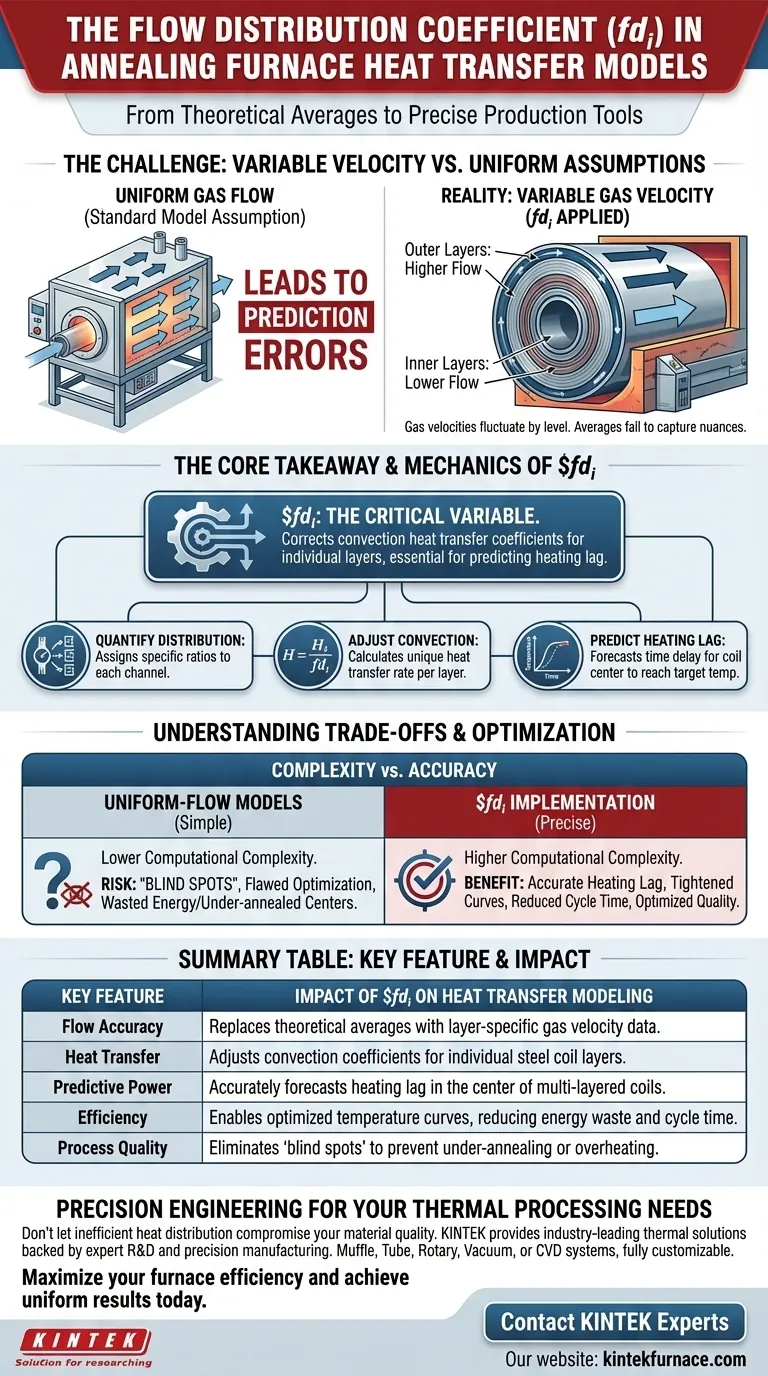

The flow distribution coefficient ($fd_i$) is the critical variable that quantifies exactly how protective gas is distributed across the various flow channels of multi-layered steel coils. By accounting for the reality that gas velocities differ at various coil levels, this coefficient allows heat transfer models to move beyond theoretical averages and simulate specific convection conditions for each layer.

Core Takeaway Standard models often assume uniform gas flow, leading to prediction errors. The $fd_i$ corrects this by adjusting convection heat transfer coefficients for individual layers, which is essential for accurately predicting heating lag and optimizing annealing temperature curves.

The Challenge of Internal Furnace Structure

The Reality of Variable Velocity

In the complex internal structure of an annealing furnace, protective gas does not flow uniformly.

Gas velocities fluctuate significantly depending on the specific level of the coil.

Why Averages Fail

Using a single, average velocity for the entire furnace oversimplifies the physical reality.

This approach fails to capture the nuances of heat transfer in multi-layered steel coils, resulting in models that cannot predict temperature variances accurately.

The Mechanics of the Coefficient

Quantifying Distribution Ratios

The primary function of the $fd_i$ is to assign a specific distribution ratio to each flow channel.

This provides a mathematical representation of how much gas is actually reaching different parts of the coil stack.

Adjusting Convection Coefficients

The flow distribution directly dictates the convection heat transfer coefficient.

By incorporating $fd_i$, the model calculates a unique heat transfer rate for each layer, rather than applying a blanket value across the entire batch.

Predicting Heating Lag

One of the most significant outcomes of using this coefficient is the ability to predict heating lag.

Because the model understands that inner layers may receive less convective flow than outer layers, it can accurately forecast the time delay required for the center of the coil to reach the target temperature.

Understanding the Trade-offs

Complexity vs. Accuracy

Implementing the flow distribution coefficient increases the computational complexity of the model compared to simple uniform-flow models.

However, omitting it leads to "blind spots" where the model assumes the steel is heated uniformly when it is not.

The Cost of Optimization

Optimizing annealing temperature curves requires precise inputs.

If the $fd_i$ is ignored or estimated poorly, the resulting optimization curves will be flawed, potentially leading to under-annealed coil centers or wasted energy from overheating outer layers.

Making the Right Choice for Your Goal

To effectively utilize the flow distribution coefficient in your heat transfer models, consider your specific objectives:

- If your primary focus is Model Fidelity: Ensure your inputs for the $fd_i$ reflect the specific geometry of your multi-layered coils to capture realistic velocity variations.

- If your primary focus is Process Efficiency: Use the heating lag predictions derived from the $fd_i$ to tighten your annealing temperature curves, reducing cycle time without compromising quality.

By shifting from assumed uniformity to calculated distribution, you transform your model from a theoretical estimate into a precise production tool.

Summary Table:

| Key Feature | Impact of $fd_i$ on Heat Transfer Modeling |

|---|---|

| Flow Accuracy | Replaces theoretical averages with layer-specific gas velocity data. |

| Heat Transfer | Adjusts convection coefficients for individual steel coil layers. |

| Predictive Power | Accurately forecasts heating lag in the center of multi-layered coils. |

| Efficiency | Enables optimized temperature curves, reducing energy waste and cycle time. |

| Process Quality | Eliminates 'blind spots' to prevent under-annealing or overheating. |

Precision Engineering for Your Thermal Processing Needs

Don't let inefficient heat distribution compromise your material quality. KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your unique metallurgical and research requirements.

Maximize your furnace efficiency and achieve uniform results today.

Visual Guide

References

- Yang Xiao-jing, Yu-Ren Li. Study of heat transfer model and buried thermocouple test of bell-type annealing furnace based on thermal equilibrium. DOI: 10.1038/s41598-025-97422-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a controlled oxygen environment necessary for high-entropy alloy powders? Master HEA Oxidation & Phase Purity

- How does the coordination between a heating furnace and a rolling mill contribute to processing high-entropy alloys?

- How does a tube atmosphere furnace facilitate the carbon coating modification of LMFP materials? Optimize Conductivity

- What role does the furnace atmosphere play in heat transfer? Optimize Your Process with KINTEK

- How does a high-temperature electric furnace facilitate the sintering process of 3Y-TZP ceramics? Master Densification

- What critical environmental controls do furnaces provide for ceramic 4D printing? Achieve Perfect Debinding Results

- How does the heating mechanism differ between a muffle furnace and an atmosphere furnace? Discover Key Design and Application Insights

- How does a laboratory electric furnace support the process of evaluating the light-off temperature of Pd/Al2O3 catalysts?