Bode plot analysis is the definitive method for quantifying the stability and responsiveness of an electric furnace temperature control system. By mapping frequency response, it translates complex feedback behavior into actionable metrics regarding phase margin, gain margin, and bandwidth. This allows engineers to predict whether the furnace will hold steady under load or oscillate dangerously.

At its core, Bode plot analysis bridges the gap between theoretical control design and operational reality. It reveals exactly how a furnace will react to external disturbances—such as power fluctuations or material loading—ensuring precise temperature regulation without instability.

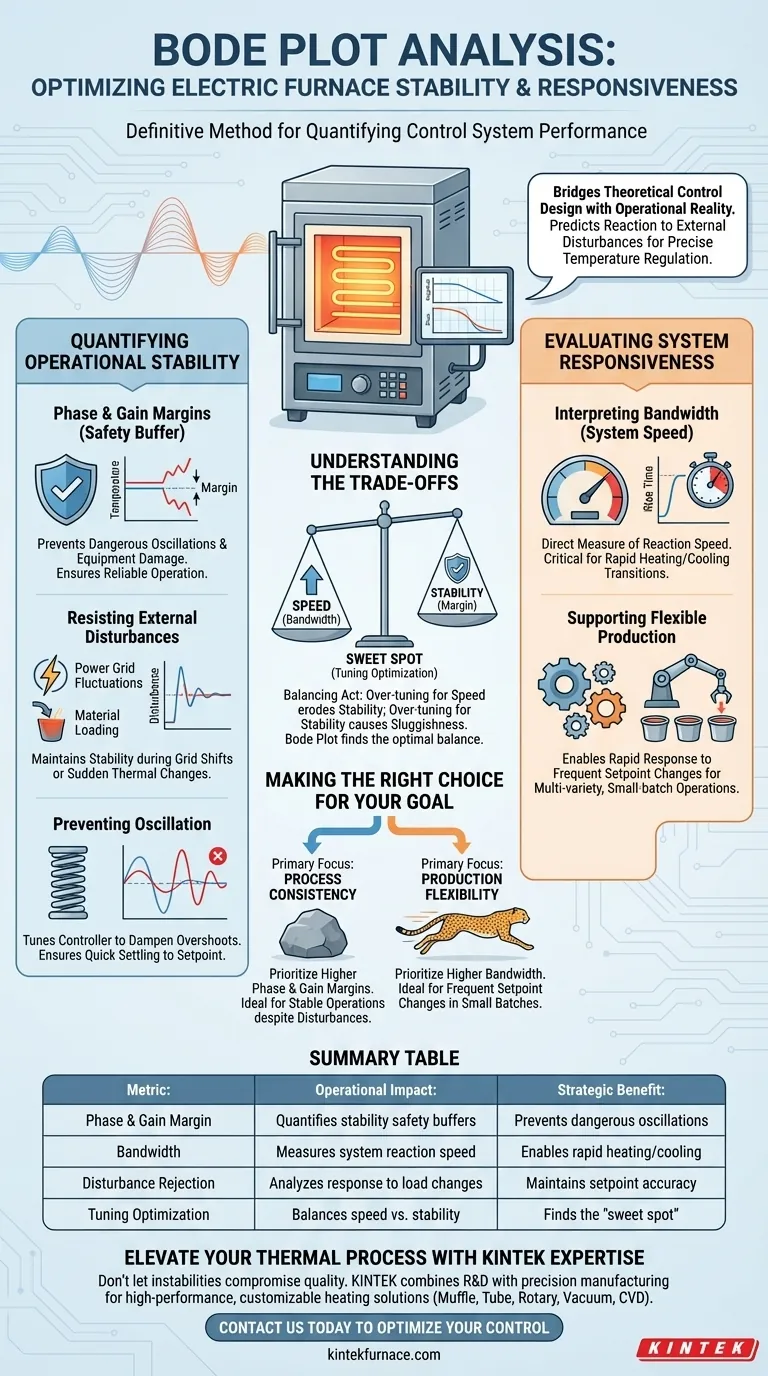

Quantifying Operational Stability

The Role of Phase and Gain Margins

Bode plots provide a visual and numerical representation of phase margin and gain margin. These metrics serve as the system's "safety buffer" against instability.

A system with sufficient margins can operate reliably without drifting into oscillation. Without these confirmed margins, the control loop risks becoming unstable, leading to temperature cycling that can damage the furnace or the product.

Resisting External Disturbances

Real-world operations are rarely static; electric furnaces face constant variables.

Bode plot analysis determines the system's ability to reject specific external disturbances. This includes maintaining stability during power grid fluctuations or sudden thermal changes caused by material loading and unloading.

Preventing Oscillation

If the control loop is too aggressive, the temperature will overshoot and undershoot the target repeatedly.

By analyzing the Bode plot, engineers can tune the controller to dampen these oscillations. This ensures the temperature settles quickly and stays at the setpoint despite environmental changes.

Evaluating System Responsiveness

Interpreting Bandwidth

The bandwidth value indicated on a Bode plot is a direct measure of the system's speed.

A higher bandwidth suggests the control system can react faster to error signals. This is critical for processes that require rapid heating or cooling transitions.

Supporting Flexible Production

Modern manufacturing often requires multi-variety, small-batch operations.

These operations demand frequent adjustments to temperature setpoints. A system with high bandwidth, verified by Bode analysis, supports these flexible requirements by responding quickly to new commands.

Understanding the Trade-offs

Balancing Speed and Stability

While high bandwidth improves response speed, pushing it too high can erode your phase margin.

There is often a natural tension between how fast a system reacts and how stable it remains. An overly fast response to setpoint changes can make the system more susceptible to noise or oscillation.

The Cost of Over-Tuning

Optimizing solely for disturbance rejection might result in a sluggish response to setpoint changes.

Conversely, optimizing solely for speed (bandwidth) might make the furnace unstable during material loading. The Bode plot is the tool used to find the mathematical "sweet spot" between these conflicting goals.

Making the Right Choice for Your Goal

To optimize your electric furnace control, you must prioritize based on your operational needs:

- If your primary focus is Process Consistency: Prioritize higher phase and gain margins to ensure the system remains stable despite grid fluctuations or heavy material loading.

- If your primary focus is Production Flexibility: Prioritize higher bandwidth to ensure the furnace responds rapidly to frequent setpoint changes typical of small-batch runs.

Mastering the Bode plot allows you to move from reactive troubleshooting to proactive system optimization.

Summary Table:

| Metric | Operational Impact | Strategic Benefit |

|---|---|---|

| Phase & Gain Margin | Quantifies stability safety buffers | Prevents dangerous oscillations and equipment damage |

| Bandwidth | Measures system reaction speed | Enables rapid heating/cooling for flexible production |

| Disturbance Rejection | Analyzes response to load changes | Maintains setpoint accuracy during power or material shifts |

| Tuning Optimization | Balances speed vs. stability | Finds the mathematical "sweet spot" for process consistency |

Elevate Your Thermal Process with KINTEK Expertise

Don’t let control instabilities compromise your production quality. KINTEK combines cutting-edge R&D with precision manufacturing to deliver high-performance heating solutions. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to meet your specific stability and responsiveness requirements.

Ready to optimize your thermal control? Contact us today to consult with our experts and discover how our advanced furnace technology can drive efficiency and consistency in your laboratory or production line.

Visual Guide

References

- Serdar Ekinci, Євген Зайцев. Efficient control strategy for electric furnace temperature regulation using quadratic interpolation optimization. DOI: 10.1038/s41598-024-84085-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Spark Plasma Sintering SPS Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the necessity of preheating reinforcement materials? Eliminate Defects in Aluminum Alloys

- How should materials with high moisture content be handled before heating? Ensure Safety and Quality in Thermal Processing

- Why is a temperature-controlled heating system required for firing silver electrodes? Ensure Precision Ohmic Contacts

- How is SEM utilized to evaluate manganese phosphate catalysts after calcination? Verify Nanosheet Integrity.

- What is the significance of high-precision temperature monitoring systems in SPS? Control Ti-6Al-4V/HA Microstructure

- What is the technical objective of performing thermal oxidation at 625 °C? Mastering SiOx Tunnel Oxide Precision

- What are the benefits of adding calcium oxide in sludge thermal treatment? Boost Efficiency & Reduce Emissions

- What is the purpose of using an Argon protective atmosphere during the casting of H13 steel? Boost Purity and Strength