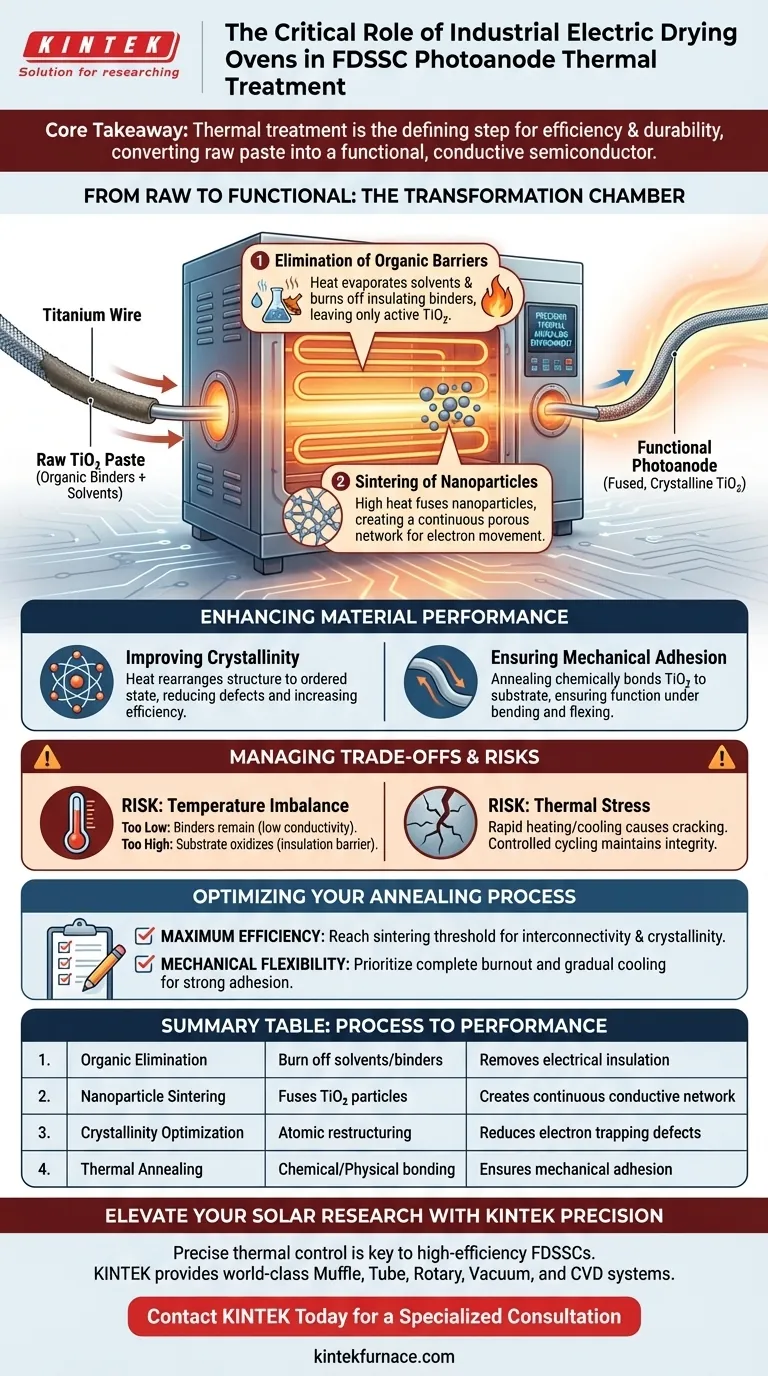

Industrial electric drying ovens act as the critical structural transformation chamber for titanium photoanodes in flexible fiber-shaped dye-sensitized solar cells (FDSSCs). They do far more than simply dry the material; they provide a precise thermal annealing environment that converts raw titanium dioxide (TiO2) paste into a functional, conductive semiconductor layer bonded to a titanium wire.

Core Takeaway The thermal treatment process is the defining step for the photoanode's efficiency and durability. It systematically eliminates organic impurities and fuses nanoparticles together, ensuring the final device creates a cohesive electrical pathway while remaining flexible enough to withstand bending.

The Mechanics of Thermal Treatment

Elimination of Organic Barriers

The raw TiO2 paste applied to the wire contains organic solvents and binders to facilitate coating. These organics are insulators that block electron flow.

The oven provides the thermal energy required to evaporate solvents and burn off binders completely. This purification leaves behind only the active titanium dioxide material needed for energy conversion.

Sintering of Nanoparticles

Simply drying the paste leaves a loose collection of particles. The oven promotes sintering, a process where high heat fuses individual TiO2 nanoparticles together.

This creates a continuous, porous network rather than isolated dust. This interconnectivity is essential for allowing electrons to move freely through the film.

Enhancing Material Performance

Improving Crystallinity

The thermal environment enhances the crystallinity of the photoanode film. Heat rearranges the atomic structure into a more ordered state.

Higher crystallinity reduces defects within the material. Fewer defects mean fewer electrons are trapped or lost, directly resulting in higher solar cell efficiency.

Ensuring Mechanical Adhesion

FDSSCs are designed to be flexible, which presents a mechanical challenge. If the coating is brittle or loose, it will flake off when the fiber is bent.

The annealing process chemically and physically bonds the TiO2 layer to the titanium wire substrate. This strong adhesion ensures the solar cell retains its function even when the fiber is flexed or twisted.

Understanding the Trade-offs

The Risk of Temperature Imbalance

Precision is paramount. If the oven temperature is too low, organic binders will remain in the film, drastically reducing conductivity.

Conversely, if the temperature is too high or the exposure too long, the titanium wire substrate may oxidize excessively, creating an insulating barrier that ruins performance.

Thermal Stress Management

The "controlled" aspect of the oven is vital for preventing thermal shock. Rapid heating or cooling can cause the ceramic-like TiO2 layer to crack.

Industrial ovens allow for specific temperature cycling—ramping heat up and down slowly—to maintain the structural integrity of the coating.

Optimizing Your Annealing Process

To achieve the best results with your industrial electric drying oven, tailor your approach to your specific performance metrics.

- If your primary focus is maximum efficiency: Ensure your temperature profile reaches the sintering threshold to maximize nanoparticle interconnectivity and crystallinity.

- If your primary focus is mechanical flexibility: Prioritize complete binder burnout and gradual cooling cycles to ensure the strongest possible adhesion to the titanium wire.

The difference between a functional FDSSC and a failing prototype often lies entirely in the precision of the thermal treatment.

Summary Table:

| Process Phase | Primary Function | Impact on Performance |

|---|---|---|

| Organic Elimination | Burn off solvents & binders | Removes electrical insulation barriers |

| Nanoparticle Sintering | Fuses TiO2 particles | Creates a continuous conductive network |

| Crystallinity Optimization | Atomic restructuring | Reduces electron trapping defects |

| Thermal Annealing | Chemical/Physical bonding | Ensures mechanical adhesion during bending |

Elevate Your Solar Research with KINTEK Precision

Precise thermal control is the difference between a high-efficiency FDSSC and a failing prototype. KINTEK provides world-class industrial electric drying ovens and high-temperature furnace systems designed to meet the rigorous demands of semiconductor and solar cell R&D.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique material needs. Ensure perfect crystallinity and mechanical adhesion every time with our industry-leading technology.

Contact KINTEK Today for a Specialized Consultation

Visual Guide

References

- Yeonggwon Kim, Hyung Woo Lee. All‐Dry Fabricated Core–Sheath Carbon Nanotube Yarn Electrode for Fiber‐Shaped Dye‐Sensitized Solar Cells. DOI: 10.1002/sstr.202500302

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1200℃ Muffle Oven Furnace for Laboratory

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Heat Treat Sintering and Brazing Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is the retention time of a rotary kiln? Optimize Your Process Efficiency

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency