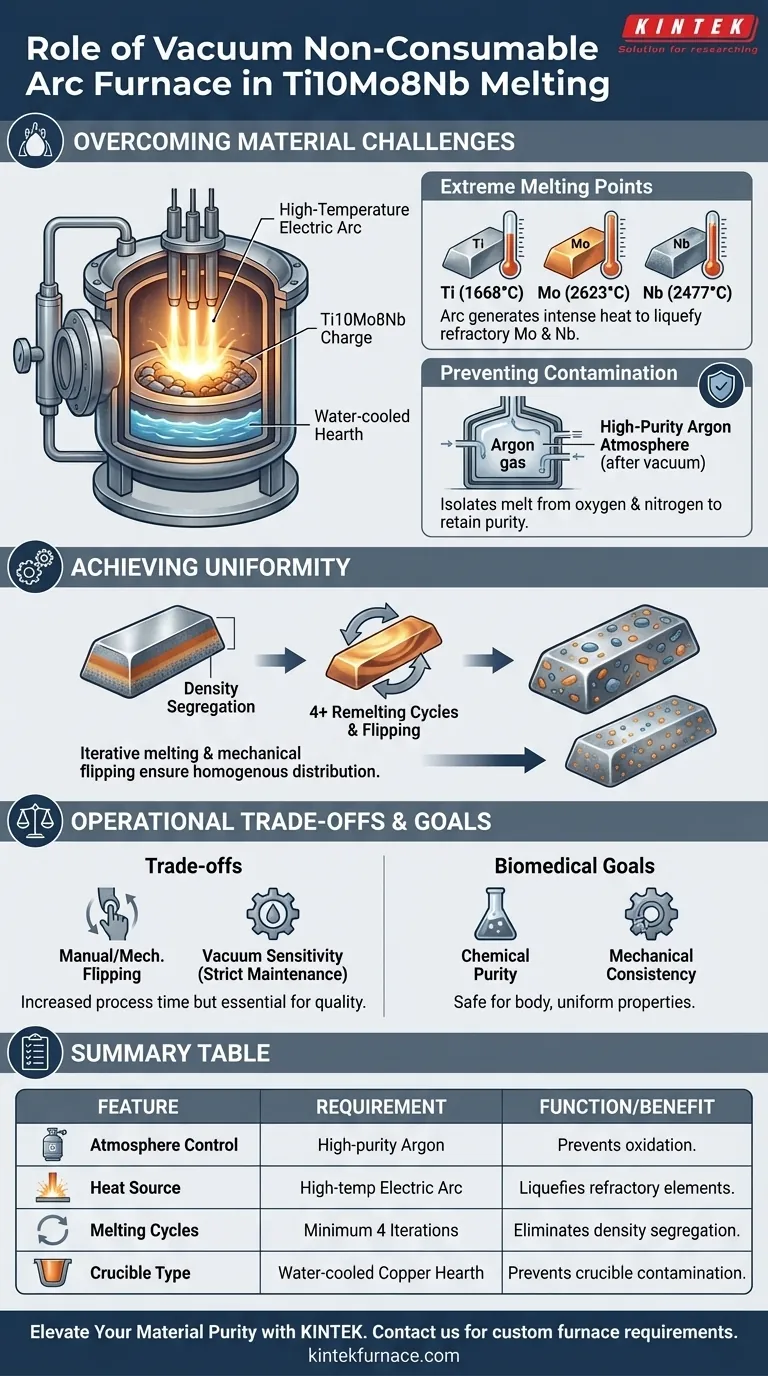

The vacuum non-consumable arc furnace serves as the critical primary processing tool for creating the Ti10Mo8Nb alloy. Its function is to melt high-melting-point raw materials—Titanium, Molybdenum, and Niobium—using high-temperature electric arcs within a controlled, high-purity argon atmosphere. This process is essential for shielding the reactive metals from oxidation while creating a homogenous mixture from elements with vastly different physical properties.

Core Insight Manufacturing Ti10Mo8Nb requires more than just high heat; it requires an environment that strictly controls chemical interactions. The vacuum non-consumable arc furnace provides the necessary inert atmosphere to maintain biomedical-grade purity, while enabling the multiple remelting cycles required to homogenize elements with disparate melting points and densities.

Overcoming Material Challenges

Handling Extreme Melting Points

The Ti10Mo8Nb alloy consists of metals with exceptionally high melting points, particularly Molybdenum and Niobium.

Standard heating methods often fail to achieve the temperatures required to fully liquefy these refractory elements. The vacuum non-consumable arc furnace utilizes high-temperature electric arcs to generate the intense, localized heat necessary to completely melt these raw materials.

Preventing Environmental Contamination

Titanium and its alloys are highly reactive chemically, especially when molten.

Exposure to oxygen, nitrogen, or carbon at high temperatures leads to the formation of oxides and brittle compounds. This furnace operates under a high-purity argon atmosphere (following vacuum evacuation), effectively isolating the melt. This prevents oxidation, ensuring the alloy retains the ductility and chemical purity required for biomedical components.

Achieving Compositional Uniformity

Addressing Density Segregation

A major challenge in melting Ti10Mo8Nb is the significant difference in density and melting points among the three constituent elements.

If melted only once, the heavier or higher-melting-point elements tend to separate from the lighter ones. This leads to segregation, where the chemical composition varies across the ingot, resulting in unpredictable mechanical properties.

The Role of Multiple Remelting Cycles

To counter segregation, the non-consumable nature of the furnace allows for a specific procedural intervention: flipping and remelting.

The alloy ingot must be mechanically flipped and remelted multiple times. For Ti10Mo8Nb specifically, at least four remelting cycles are required. This iterative process mechanically and thermally forces the elements to mix, ensuring a uniform distribution of Molybdenum and Niobium within the Titanium matrix at both macroscopic and microscopic scales.

Operational Trade-offs

Process Intensity vs. Uniformity

While this furnace type excels at melting refractory metals, it relies on localized arc heating.

This requires careful management of the melt pool to ensure the entire volume is liquid. The necessity of manual or mechanical flipping between cycles increases processing time and labor compared to continuous casting methods, but it is non-negotiable for achieving the homogeneity required for high-performance alloys.

Sensitivity to Vacuum Levels

The quality of the final alloy is entirely dependent on the integrity of the vacuum and inert gas system.

Even minor leaks or low-purity argon can introduce interstitial elements (like Oxygen) that ruin the material's biomedical viability. The equipment demands rigorous maintenance to hold high vacuum levels (e.g., 3 x 10⁻³ Pa range) to prevent "alpha-case" formation or embrittlement.

Ensuring Quality for Biomedical Applications

The ultimate goal of using this furnace is to produce an ingot that is chemically safe for the human body and mechanically consistent.

- If your primary focus is Chemical Purity: Prioritize the vacuum evacuation phase and the purity grade of the argon gas to prevent oxidation and surface contamination.

- If your primary focus is Mechanical Consistency: Adhere strictly to the minimum of four remelting cycles to eliminate segregation caused by density differences.

By strictly controlling the atmosphere and the remelting schedule, this furnace converts raw, disparate metals into a unified, high-performance biomedical foundation.

Summary Table:

| Feature | Requirement for Ti10Mo8Nb Alloy | Function/Benefit |

|---|---|---|

| Atmosphere Control | High-purity Argon (after $3 \times 10^{-3}$ Pa vacuum) | Prevents oxidation and contamination of reactive Titanium |

| Heat Source | High-temperature Electric Arc | Liquefies refractory elements like Molybdenum and Niobium |

| Melting Cycles | Minimum 4 Remelting Iterations | Eliminates density segregation and ensures chemical uniformity |

| Crucible Type | Water-cooled Copper Hearth | Prevents contamination from crucible material (Non-consumable) |

Elevate Your Material Purity with KINTEK

Precise control over high-melting-point alloys like Ti10Mo8Nb requires advanced thermal technology. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, CVD, and high-temperature furnace systems tailored to your specific research or production needs. Whether you require standard equipment or a fully customizable solution to prevent oxidation and ensure homogeneity, our team is ready to support your lab's next breakthrough.

Ready to achieve biomedical-grade precision? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Edwin Gilberto Medina Bejarano, Daniela Sachs. Evaluation of corrosion resistance and biocompatibility test of Ti10Mo8Nb alloy for biomedical applications. DOI: 10.33448/rsd-v14i5.48744

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a vacuum non-consumable arc furnace play in high-entropy alloys? Master Complex Alloy Synthesis

- What is the function of a high-temperature vacuum induction furnace in (Hf─Zr─Ti)C synthesis? Achieve 2100°C Precision

- What are the fundamental principles behind induction heating? Unlock Efficient, Non-Contact Heat for Your Lab

- Why is an induction furnace equipped with a graphite susceptor necessary? Achieving Precision for Electrical Steel

- How do MgO crucibles affect melt purity? Strategies for High-Purity Vacuum Induction Remelting

- What role does electromagnetic stirring play in vacuum induction melting? Enhance Alloy Quality and Efficiency

- What are the key features of a medium frequency induction furnace? Unlock Faster, Cleaner Metal Processing

- What type of heating system is commonly used in vacuum casting furnaces and how does it work? Discover Induction Heating for Pure, Efficient Melting