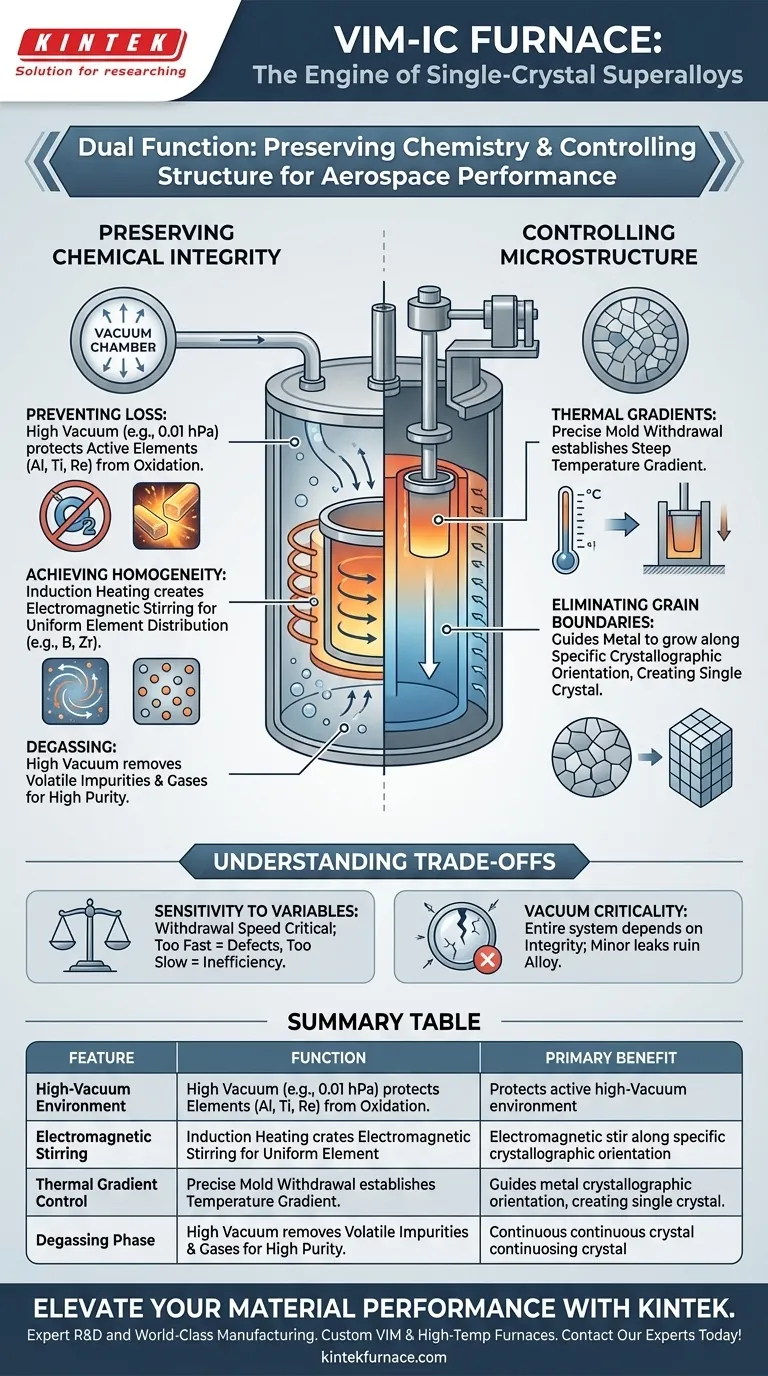

The Vacuum Induction Melting Directional Solidification (VIM-IC) furnace serves as the foundational processing unit for creating high-performance aerospace components. It performs two simultaneous functions: it maintains a pristine vacuum environment to preserve the alloy's complex chemistry and utilizes a precise mechanical withdrawal system to force the metal to solidify as a single, continuous crystal.

Core Takeaway The VIM-IC furnace solves the dual challenge of chemical reactivity and structural weakness. by combining high-vacuum melting with controlled thermal gradients, it enables the production of superalloys that retain reactive elements (like aluminum and titanium) while eliminating grain boundaries, resulting in superior high-temperature creep resistance.

Preserving Chemical Integrity

The first critical role of this equipment is to act as a protective barrier during the melting phase. Nickel-based superalloys rely on a precise cocktail of reactive elements to function.

Preventing Elemental Loss

Superalloys contain active elements such as aluminum, titanium, and rhenium. These elements have a high affinity for oxygen.

If melted in air, they would instantly oxidize, forming slag rather than strengthening the alloy. The VIM-IC furnace creates a high-vacuum environment (often as low as 0.01 hPa) that effectively prevents this oxidation, ensuring these active elements remain in the solution to perform their intended function.

Achieving Homogeneity via Stirring

Melting is not enough; the mix must be perfect. The induction heating mechanism inherently generates electromagnetic stirring within the melt.

This constant motion ensures that trace elements, such as boron and zirconium, are distributed uniformly throughout the nickel matrix. This prevents segregation, where elements might clump together and create weak spots in the final component.

Degassing the Melt

The vacuum environment serves an active purification role.

At high pressures (typically 1.4 to 5.3 Pa), the furnace facilitates the removal of volatile impurities and gases trapped in the raw material. This "degassing" step is vital for achieving the high purity required for aerospace engine hot-section components.

Controlling Microstructure Growth

Once the alloy is melted and chemically perfect, the furnace shifts to its second role: controlling how that liquid turns back into a solid.

Establishing Thermal Gradients

The furnace features a precise mold shell movement control system.

By mechanically withdrawing the ceramic mold from the heating zone into a cooling zone at a strictly controlled speed, the furnace establishes a steep temperature gradient. This forces the solidification front to move in one specific direction.

Eliminating Grain Boundaries

In standard casting, metal cools from all sides, creating a chaotic "polycrystalline" structure with many grain boundaries.

Grain boundaries are the weak links where cracks form under high heat and stress. The VIM-IC process guides the metal to grow along a specific crystallographic orientation. This effectively eliminates grain boundaries, producing a single-crystal structure that offers maximum resistance to thermal creep.

Understanding the Trade-offs

While the VIM-IC process is the gold standard for high-performance alloys, it introduces specific complexities that must be managed.

Sensitivity to Process Variables

The "withdrawal speed" mentioned in the primary reference is a double-edged sword.

If the withdrawal is too fast, the thermal gradient breaks down, leading to "stray grains" (defects) that ruin the single-crystal nature. If it is too slow, production efficiency drops, and element segregation can occur. The equipment requires absolute precision to maintain the balance.

Vacuum Maintenance Criticality

The system is entirely dependent on vacuum integrity.

Even a minor leak or failure in the vacuum pumps can introduce enough oxygen to consume the active elements (Al/Ti/Nb), altering the alloy's chemical composition. This renders the material off-spec before solidification even begins.

Making the Right Choice for Your Goal

The VIM-IC furnace is a complex tool designed for a specific set of high-stakes outcomes.

- If your primary focus is High-Temperature Creep Resistance: Prioritize the precision of the withdrawal system and thermal gradient controls, as these directly dictate the quality of the single-crystal structure.

- If your primary focus is Alloy Compositional Accuracy: Focus on the vacuum capacity and electromagnetic stirring efficiency to ensure reactive elements like Rhenium and Aluminum are preserved and homogenized.

Ultimately, the VIM-IC furnace is the gatekeeper that transforms raw chemical potential into the structural reality required for modern aerospace propulsion.

Summary Table:

| Feature | Function in VIM-IC Process | Primary Benefit |

|---|---|---|

| High-Vacuum Environment | Prevents oxidation of reactive elements (Al, Ti, Re) | Maintains precise chemical composition |

| Electromagnetic Stirring | Ensures uniform element distribution | Prevents material segregation and weak spots |

| Thermal Gradient Control | Manages solidification front via mold withdrawal | Eliminates grain boundaries for creep resistance |

| Degassing Phase | Removes volatile impurities and trapped gases | Achieves high-purity aerospace-grade material |

Elevate Your Material Performance with KINTEK

Precision is the difference between a high-performance superalloy and a structural failure. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Vacuum Induction Melting (VIM) systems and custom lab high-temperature furnaces designed to meet the rigorous demands of aerospace and materials science.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our equipment is fully customizable to your unique thermal processing needs. Transform your raw material potential into reality today—Contact our technical experts at KINTEK to discuss your custom furnace solution.

Visual Guide

References

- Kamil Gancarczyk, Maciej Motyka. The Effect of Re Content on Microstructure and Creep Resistance of Single Crystal Castings Made of Nickel-Based Superalloys. DOI: 10.12913/22998624/178463

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a non-consumable vacuum arc furnace play in Ti–Cu alloy preparation? Achieving High-Purity Synthesis

- What is the application of induction furnace? Melt Metal with Unmatched Purity and Efficiency

- What role does a vacuum arc melting furnace with a non-consumable electrode play? Key to CuAlMn Shape Memory Alloys

- What role do vacuum induction furnaces play in nickel-based superalloys? Precision Melting for High-Performance Metals

- What are the technical advantages of using an induction furnace for lithium battery recycling over resistance heating?

- Why are multiple vacuum-argon cycles necessary for an induction heating furnace? Ensure Pure Combustion Synthesis

- What are the experimental advantages of using a vacuum induction furnace for cast iron desulfurization research?

- Why is a Vacuum Induction Melting furnace (VIM) used for Cu-Zn-Al-Sn alloys? Achieve Precision Composition Control