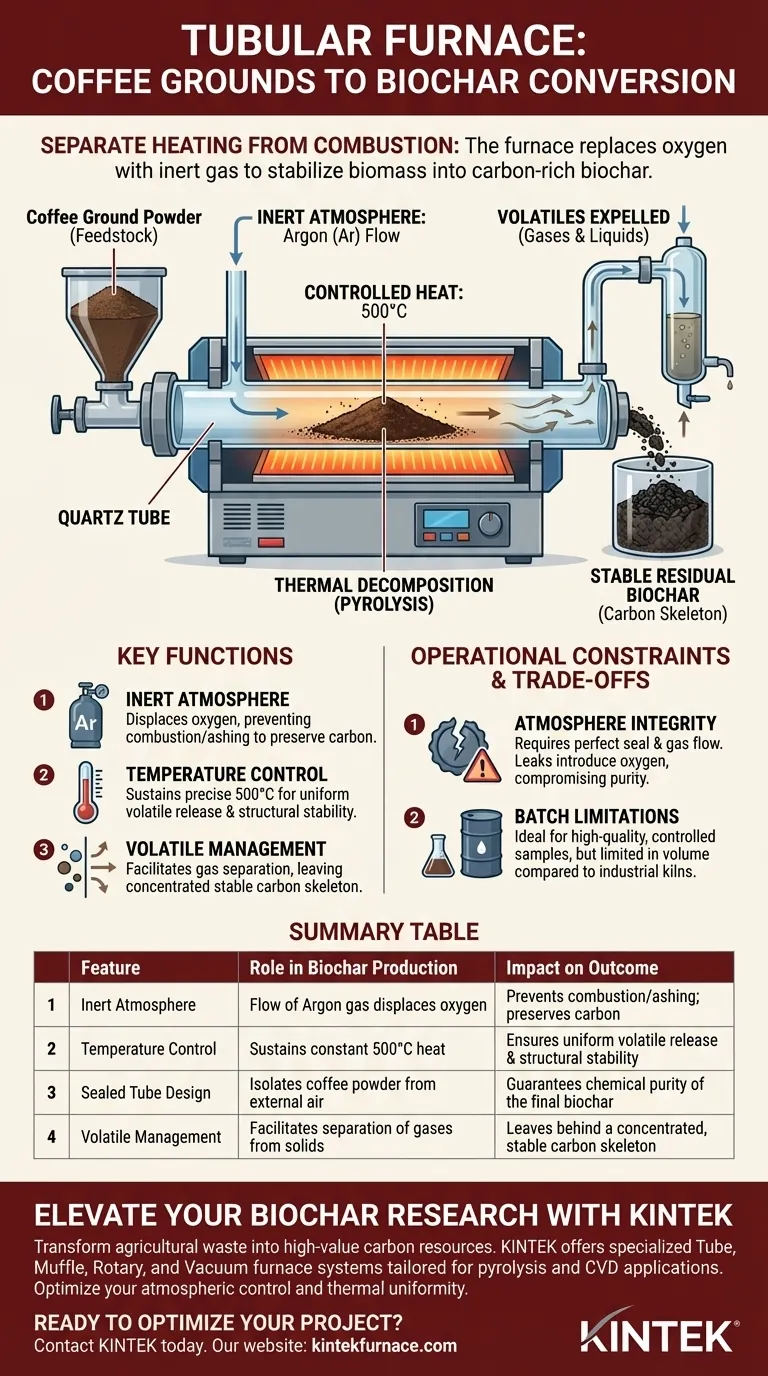

The primary role of a tubular furnace in this process is to create a sealed, oxygen-free reaction chamber essential for pyrolysis. Specifically, it maintains a controlled Argon (Ar) atmosphere while heating fine coffee powder to 500 °C. This precise environment ensures the biomass thermally decomposes into stable biochar rather than simply burning into ash.

Core Takeaway To convert coffee grounds into biochar, you must separate heating from combustion. The tubular furnace solves this by replacing oxygen with inert gas, forcing the organic matter to release volatiles and stabilize into a carbon-rich solid structure.

Creating the Pyrolysis Environment

The Necessity of an Inert Atmosphere

The fundamental requirement for converting coffee grounds to biochar is the exclusion of oxygen.

The tubular furnace utilizes a sealed design that allows for the continuous flow of Argon (Ar) gas. This creates an inert "blanket" around the coffee powder.

Without this specific atmosphere control, introducing heat would trigger oxidation, reducing your feedstock to useless ash instead of functional biochar.

Thermal Treatment of Fine Powder

The furnace is designed to handle fine coffee powder, ensuring uniform heat distribution.

By maintaining a steady temperature of 500 °C, the furnace provides the energy required to break down the complex organic structures found in coffee grounds.

Regulating the Chemical Transformation

Expelling Volatile Substances

As the coffee powder reaches the target temperature, the furnace facilitates the release of volatile components.

These unstable elements are driven off as gas, leaving behind the solid carbon skeleton. The tubular design ensures these volatiles are effectively separated from the solid residue.

Stabilizing the Biochar

The ultimate goal of this thermal treatment is stability.

The furnace's ability to hold the material at 500 °C under Argon allows the remaining organic matter to reorganize. This results in a "stable residual biochar" that resists biological degradation and retains its structure.

Operational Constraints and Trade-offs

Sensitivity to Atmosphere Integrity

The effectiveness of a tubular furnace relies entirely on the integrity of the seal and gas flow.

If the Argon supply is interrupted or the tube leaks, oxygen will enter the system. This will immediately compromise the purity of the biochar and alter the surface functional groups.

Batch Limitations

Tubular furnaces are generally designed for precision rather than high-volume throughput.

While excellent for producing high-quality, scientifically controlled samples of coffee biochar, they may be volume-limited compared to large-scale industrial kilns.

Optimizing Your Biochar Production

To achieve the best results with your coffee ground feedstock, consider the following approach:

- If your primary focus is Chemical Purity: Ensure a continuous, high-purity Argon flow to completely exclude oxygen and prevent surface oxidation.

- If your primary focus is Structural Consistency: Use the furnace's precise temperature control to maintain exactly 500 °C, ensuring uniform volatile release across the fine powder.

The tubular furnace is the critical isolation tool that dictates the chemical destiny of your coffee waste, transforming it from a byproduct into a stable carbon resource.

Summary Table:

| Feature | Role in Biochar Production | Impact on Outcome |

|---|---|---|

| Inert Atmosphere | Flow of Argon gas displaces oxygen | Prevents combustion/ashing; preserves carbon |

| Temperature Control | Sustains constant 500 °C heat | Ensures uniform volatile release & structural stability |

| Sealed Tube Design | Isolates coffee powder from external air | Guarantees chemical purity of the final biochar |

| Volatile Management | Facilitates separation of gases from solids | Leaves behind a concentrated, stable carbon skeleton |

Elevate Your Biochar Research with KINTEK

Transform agricultural waste into high-value carbon resources with precision and ease. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, and Vacuum furnace systems tailored for advanced pyrolysis and CVD applications. Whether you are processing coffee grounds or developing new nanomaterials, our customizable high-temp solutions provide the exact atmospheric control and thermal uniformity your lab requires.

Ready to optimize your carbon sequestration or material synthesis?

Contact KINTEK today to discuss your unique project needs

Visual Guide

References

- Arunakumari Nulu, Keun Yong Sohn. N-doped CNTs wrapped sulfur-loaded hierarchical porous carbon cathode for Li–sulfur battery studies. DOI: 10.1039/d3ra08507d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the different types of tube furnaces and their features? Choose the Right Furnace for Your Lab

- What components are in a turn-key quartz tube furnace? Essential parts for precise atmospheric control.

- What materials are commonly used for the heating tube in a 70mm tube furnace? Optimize Your High-Temp Experiments

- Why is a fixed-bed tubular reactor used for the in-situ reduction process? Enhance Catalyst Activation Efficiency

- How does a three-tube diffusion furnace ensure the quality of thermal oxidation layers? Achieve High-Efficiency Passivation

- What role does a tube high-temperature furnace play in the synthesis of nano carbon spheres? Unlock sp2 Hybridization

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What critical conditions does a high-precision tube furnace provide? Optimize Catalyst Reduction & Particle Control