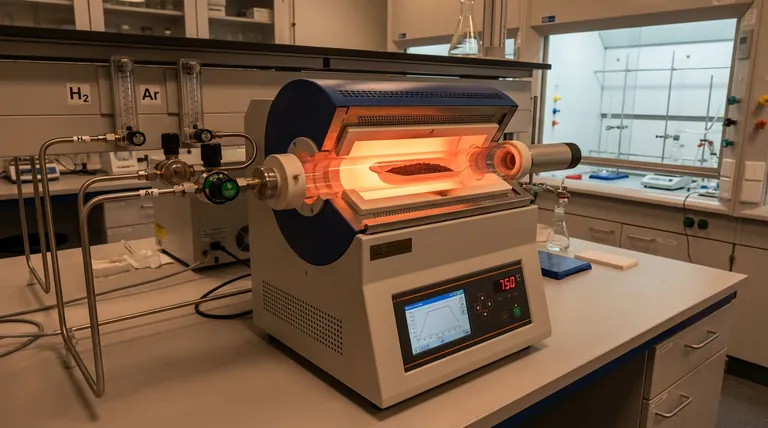

A high-precision tube furnace serves as the definitive control environment for catalyst activation. During the reduction phase of methane decomposition catalysts, specifically nickel-copper systems, it provides a strictly controlled thermochemical environment. By synchronizing a stable reducing atmosphere (typically Hydrogen/Argon) with accurate heating rates, the furnace ensures the complete transformation of oxide precursors into a metallic state.

Core Takeaway The definitive value of a tube furnace lies in its ability to synchronize atmosphere stability with thermal precision. This dual control is required to reduce oxide precursors into uniform metallic alloys while strictly regulating particle size and the degree of alloying.

The Role of Atmosphere Control

Creating a Stable Reducing Environment

To facilitate the reduction phase, the furnace must maintain a stable reducing atmosphere. This commonly involves a precise mixture of hydrogen and argon.

Ensuring Complete Precursor Transformation

The primary goal of this atmosphere is to ensure that nickel-copper oxide precursors are completely reduced to a metallic state. Without this strictly controlled gas environment, the chemical transformation remains partial or inefficient.

Promoting Uniform Alloy Formation

A consistent atmosphere is critical for the micro-structure of the catalyst. It promotes the formation of uniform NiCu alloy particles, which are essential for the catalyst's final performance in methane decomposition.

The Criticality of Thermal Precision

Regulating the Heating Rate

The furnace does not simply heat the material; it accurately controls the heating rate. This dynamic control allows the material to evolve structurally without thermal shock or uneven reaction kinetics.

Controlling Initial Metal Particle Size

Precise temperature control is the governing factor for the physical geometry of the catalyst. It directly regulates the initial metal particle size, preventing the agglomeration that can occur under unregulated thermal conditions.

Determining the Degree of Alloying

Beyond particle size, thermal precision dictates the chemical mixing of the metals. Strict temperature regulation is essential for establishing the correct degree of alloying between nickel and copper components.

Understanding the Trade-offs

The Risk of Thermal Fluctuation

If the furnace fails to maintain constant temperature precision, the catalyst suffers from sintering. This leads to enlarged particle sizes and a loss of active surface area, significantly degrading performance.

Atmosphere Inconsistencies

A furnace with poor sealing or flow control cannot maintain the strict H2/Ar ratio required. This inconsistency leads to incomplete reduction, leaving residual oxides that fail to participate in the methane decomposition reaction.

Making the Right Choice for Your Synthesis

To maximize the efficiency of your methane decomposition catalysts, align your furnace parameters with your specific structural goals.

- If your primary focus is Particle Uniformity: Prioritize a furnace with exceptional heating rate control to regulate the nucleation and growth of metal particles.

- If your primary focus is Alloy Composition: Ensure your system has a high-integrity sealing system to maintain the exact Hydrogen/Argon partial pressures required for complete reduction.

Success in catalyst synthesis depends not just on the chemistry, but on the absolute rigorous control of the thermal and atmospheric environment.

Summary Table:

| Critical Condition | Impact on Catalyst Synthesis | Key Benefit |

|---|---|---|

| Atmosphere Stability | Ensures complete reduction of NiCu oxide precursors | High-purity metallic state |

| Thermal Precision | Regulates nucleation and heating rates | Controlled initial particle size |

| Alloy Regulation | Facilitates uniform NiCu chemical mixing | Optimized catalytic performance |

| System Integrity | Prevents sintering and atmospheric leaks | Maximum active surface area |

Elevate Your Catalyst Synthesis with KINTEK Precision

Maximize the efficiency of your methane decomposition catalysts with our rigorous thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for high-stakes laboratory research. Whether you need absolute atmospheric integrity for NiCu alloying or precise heating rate control to prevent sintering, our high-temp furnaces provide the definitive control environment your materials demand.

Ready to achieve superior particle uniformity and alloy composition? Contact KINTEK today to discuss your unique needs.

References

- Suzan E. Schoemaker, Petra E. de Jongh. Balancing act: influence of Cu content in NiCu/C catalysts for methane decomposition. DOI: 10.1039/d4ma00138a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role do quartz vacuum tubes play in the synthesis of Cu2Se precursors? Ensure Purity & Precise Stoichiometry

- What is a vacuum tube furnace? Essential for High-Purity Material Processing

- What safety features are included in an atmosphere tube furnace? Essential Systems for Secure High-Temp Operations

- What is the primary function of a Drop Tube Furnace in iron ore beneficiation? Unlock High-Precision Thermal Shock.

- What conditions does a laboratory tube furnace provide for PtS/Ti3C2Tx preparation? Master 300°C Thermal Decomposition

- Why is a high-temperature tube furnace required for LNMO synthesis? Achieve Precise Fd-3m Spinel Structures

- What role does a high-temperature tube furnace play in transforming photopolymerized parts into fully aromatic polyimide?

- What is the core role of a tube furnace in synthesizing magnetic carbon-based composites? Expert Insights