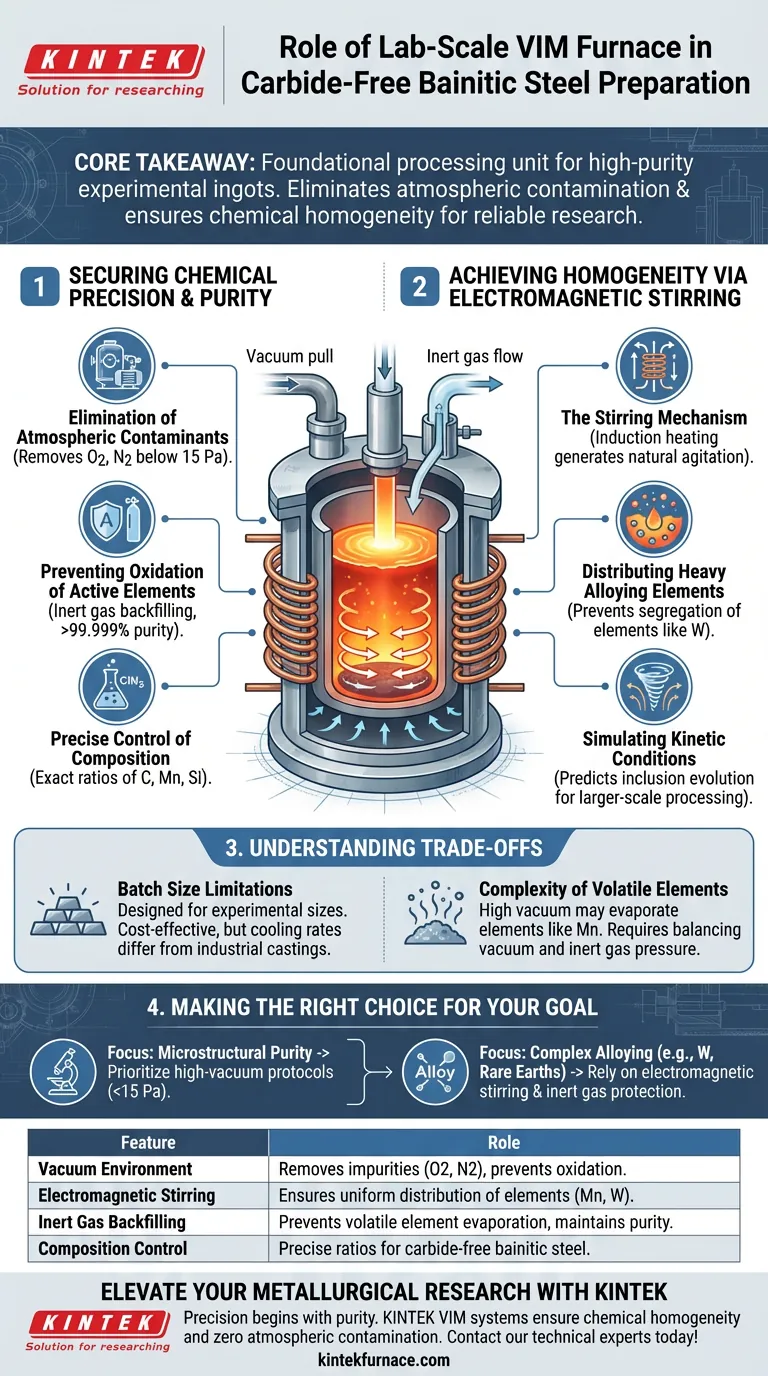

The role of a laboratory-scale vacuum induction melting (VIM) furnace is to serve as the foundational processing unit for creating high-purity experimental steel ingots. By melting raw materials in a controlled vacuum or inert gas environment, the furnace prevents oxidation and ensures the precise chemical composition required to develop carbide-free bainitic steel.

Core Takeaway The reliability of carbide-free bainitic steel research depends entirely on the quality of the initial ingot. The VIM furnace eliminates atmospheric contamination and utilizes electromagnetic stirring to guarantee the chemical homogeneity and purity necessary for accurate microstructural transformation studies.

Securing Chemical Precision and Purity

Elimination of Atmospheric Contaminants

The primary function of the VIM furnace is to isolate the molten steel from the ambient atmosphere. By using mechanical pumps to reduce chamber pressure (often below 15 Pa), the process effectively removes impurity gases like oxygen and nitrogen.

Preventing Oxidation of Active Elements

High-temperature melting in an open atmosphere typically leads to the rapid oxidation of alloying elements. The VIM furnace mitigates this by maintaining a vacuum or backfilling the chamber with high-purity argon (purity >99.999%).

Precise Control of Composition

Developing carbide-free bainitic steel requires exact ratios of carbon, manganese, and silicon to suppress cementite precipitation. The controlled environment minimizes element loss, ensuring the final chemical composition matches the theoretical design.

Achieving Homogeneity via Electromagnetic Stirring

The Stirring Mechanism

Beyond simple melting, the furnace utilizes the physics of induction heating to generate an electromagnetic stirring effect. This natural agitation promotes the uniform distribution of liquid components within the melt.

Distributing Heavy Alloying Elements

In complex steel chemistries, elements with high density differences, such as tungsten, can settle or segregate. Electromagnetic stirring forces these heavy elements to mix thoroughly, preventing segregation defects in the solidified ingot.

Simulating Kinetic Conditions

The stirring action does more than mix; it simulates the kinetic conditions necessary for studying inclusion evolution. This allows researchers to predict how non-metallic inclusions will behave during larger-scale processing.

Understanding the Trade-offs

Batch Size Limitations

As a "laboratory-scale" device, this furnace is designed for small, experimental ingots. While this allows for cost-effective iteration, the cooling rates and solidification structures may differ from those seen in massive industrial castings.

Complexity of Volatile Elements

While the vacuum prevents oxidation, high vacuum levels can occasionally cause the evaporation of highly volatile elements like manganese. Operators must carefully balance vacuum pressure with inert gas backfilling (e.g., to 500 mbar) to retain these elements while excluding oxygen.

Making the Right Choice for Your Goal

To maximize the utility of a laboratory-scale VIM furnace for your research, align your process parameters with your specific objectives:

- If your primary focus is microstructural purity: Prioritize high-vacuum protocols (<15 Pa) to maximize the removal of oxygen and nitrogen inclusions.

- If your primary focus is complex alloying (e.g., Tungsten/Rare Earths): Rely on the electromagnetic stirring capability and inert gas protection to ensure homogeneous distribution without oxidation loss.

The VIM furnace is not just a melting tool; it is the precision instrument that establishes the baseline quality for all subsequent heat treatment and material property analysis.

Summary Table:

| Feature | Role in Carbide-Free Bainitic Steel Preparation |

|---|---|

| Vacuum Environment | Removes impurities (O2, N2) and prevents oxidation of active elements. |

| Electromagnetic Stirring | Ensures uniform distribution of heavy alloying elements (Mn, W). |

| Inert Gas Backfilling | Prevents evaporation of volatile elements while maintaining purity. |

| Composition Control | Precise element ratios to suppress cementite precipitation. |

Elevate Your Metallurgical Research with KINTEK

Precision in carbide-free bainitic steel begins with the purity of your ingot. KINTEK provides state-of-the-art laboratory high-temperature furnaces, including advanced Vacuum Induction Melting (VIM) systems, designed to meet the rigorous demands of material science.

Backed by expert R&D and world-class manufacturing, our customizable solutions—from Muffle and Tube furnaces to Vacuum and CVD systems—ensure your research is built on a foundation of chemical homogeneity and zero atmospheric contamination.

Ready to optimize your lab's thermal processing? Contact our technical experts today to discuss your unique project requirements and discover how KINTEK can enhance your material development.

Visual Guide

References

- Impact Toughness and Fatigue Crack Propagation in Carbide‐Free Bainite: The Adverse Role of Retained Austenite and Martensite‐Austenite Islands. DOI: 10.1111/ffe.70025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of the melting furnace and stirring device in AFS precursor preparation? Optimize Melt Stability

- What should be considered when selecting an induction melting furnace? Key Factors for Optimal Performance

- What is vacuum melting technology and how does it work? Unlock Pure, High-Performance Metals

- What is the role of the vacuum system in a vacuum casting furnace? Ensure Purity and Performance in Metal Casting

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the limitations of vacuum casting? Key Constraints for Prototyping and Low-Volume Production

- What is inductive stirring and how does it work? Master Molten Metal Mixing for Superior Alloys

- What safety advantages do induction gold melting furnaces offer? Flameless, Contained Melting for Maximum Operator Safety