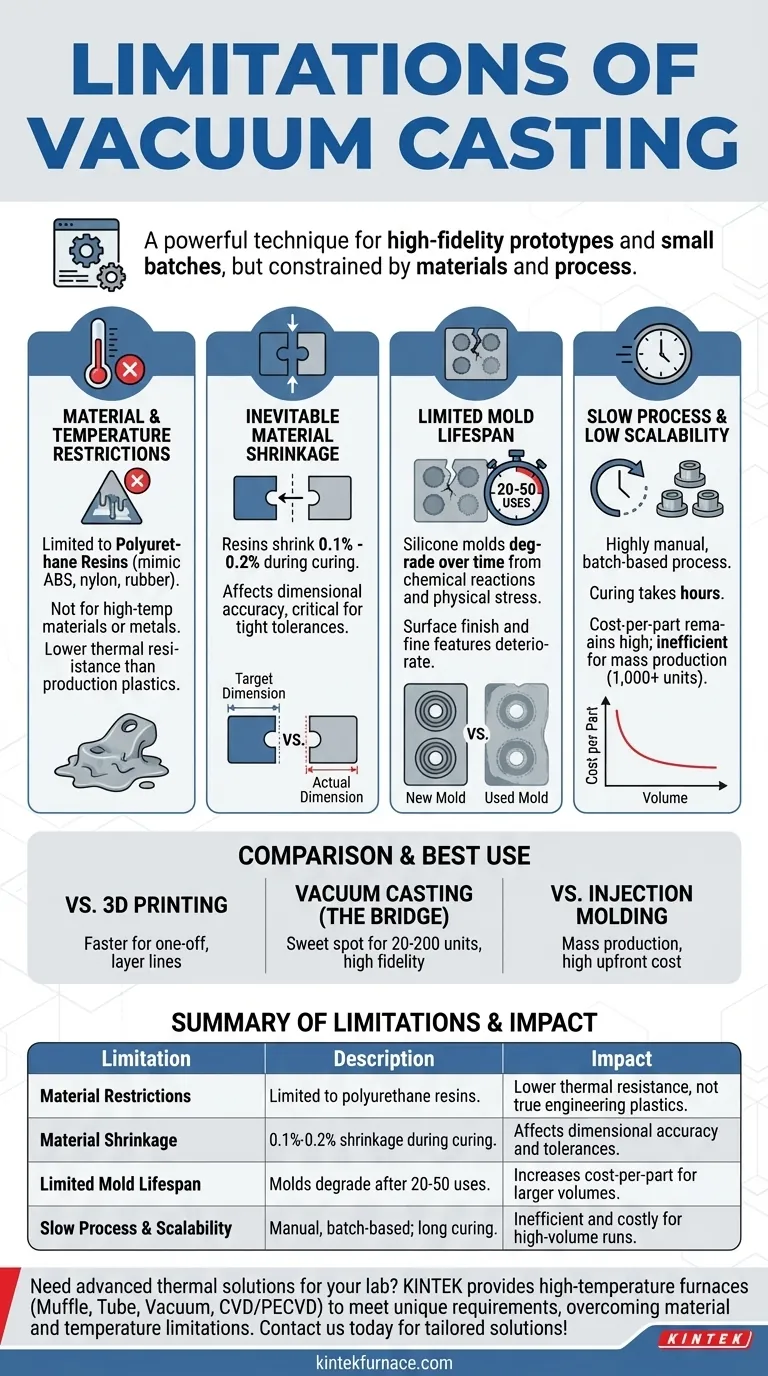

At its core, vacuum casting is a powerful technique for creating high-fidelity prototypes, but it is fundamentally constrained by its materials and process. Its primary limitations are a narrow range of usable polymers, inevitable part shrinkage, a slow production speed unsuitable for mass manufacturing, and the limited lifespan of its silicone molds.

While vacuum casting excels at producing small batches of visually and texturally accurate parts, it is not a direct replacement for mass-production methods like injection molding. Understanding its limitations is key to using it effectively for its intended purpose: rapid, high-quality prototyping and low-volume production runs.

To Understand the Limits, First Understand the Process

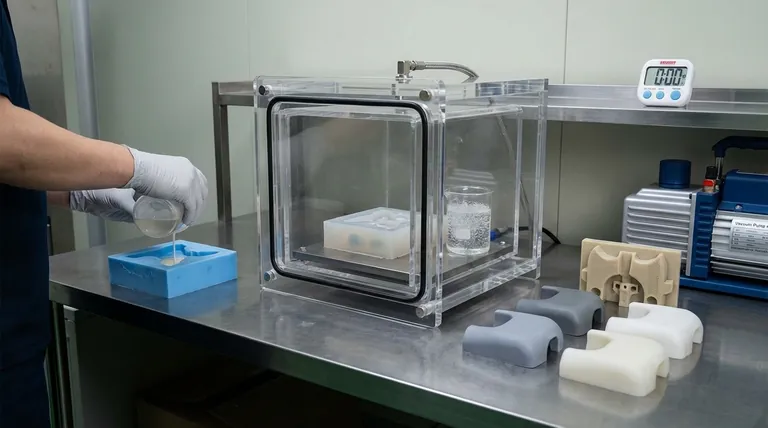

Vacuum casting is a multi-step process that uses a soft silicone mold to create plastic parts. The "vacuum" is critical because it removes air bubbles from the liquid resin as it's poured, ensuring a flawless, bubble-free final part that perfectly captures surface detail.

Step 1: The Master Pattern

First, a perfect "master" version of the part is created. This is typically done using a high-resolution 3D printer (like SLA) or CNC machining. The quality of the final cast parts can never exceed the quality of this master pattern.

Step 2: The Silicone Mold

This master pattern is suspended in a box and liquid silicone is poured around it. After curing in an oven, the silicone is carefully cut open and the master pattern is removed. This leaves a hollow cavity that is an exact negative impression of the part.

Step 3: Casting the Part

Two-part liquid polyurethane resins are mixed and then placed inside a vacuum chamber. The vacuum removes all dissolved air from the resin. The resin is then poured into the silicone mold, still under vacuum, filling the cavity completely before it is cured.

Key Limitations of Vacuum Casting Explained

The elegance of the vacuum casting process is also the source of its limitations. Each constraint stems directly from the materials and manual steps involved.

Material and Temperature Restrictions

The process is almost exclusively limited to a family of materials called polyurethane resins. While these resins can mimic the properties of production plastics like ABS, nylon, and rubber, they are not the real thing.

Furthermore, because the silicone mold is soft and has a low melting point, vacuum casting cannot be used for high-temperature materials or metals. The final parts themselves also generally have lower thermal resistance than their injection-molded counterparts.

Inevitable Material Shrinkage

All polyurethane resins shrink slightly as they cure and harden. This shrinkage rate, typically between 0.1% and 0.2%, can affect the final dimensions of the part.

While this is often negligible for many applications, it can be a critical issue for components that require extremely tight tolerances for assembly or function. The effect is often more pronounced in thicker sections of a part.

Limited Mold Lifespan

A single silicone mold is not permanent. The combination of chemical reactions with the resin and the physical stress of demolding each part causes the mold to degrade over time.

Typically, a single mold can produce only 20 to 50 parts before the surface finish degrades and fine features lose their sharpness. This inherent limitation is a primary reason why vacuum casting is not viable for large-scale production.

Slow Process and Low Scalability

Vacuum casting is a highly manual, batch-based process. The curing time for each part can range from under an hour to several hours, depending on the resin and part geometry.

When you combine the manual labor of mixing, pouring, and demolding with the limited mold life, it becomes clear that the process cannot scale efficiently. The cost-per-part remains relatively high and does not decrease significantly with volume, unlike injection molding.

Understanding the Trade-offs

Choosing a manufacturing process is always about balancing cost, speed, and quality. The limitations of vacuum casting become clearer when compared to other common methods.

Versus 3D Printing

3D printing is faster for a single, one-off part. However, vacuum casting is often faster and more cost-effective when you need 10-50 copies. Critically, vacuum casting produces parts with superior, isotropic material properties and a surface finish that is free of layer lines.

Versus Injection Molding

Injection molding is the undisputed champion of mass production. It uses durable steel molds that can produce millions of parts at a very low cost-per-part. However, the upfront cost and lead time to create that steel mold are immense (tens of thousands of dollars and weeks or months).

Vacuum casting serves as the perfect bridge, allowing you to test a design with a few dozen high-quality parts before committing to the massive expense of an injection mold.

Making the Right Choice for Your Goal

Use vacuum casting when its strengths align with your project stage and goals. Avoid it when its limitations conflict with your core requirements.

- If your primary focus is creating a few high-fidelity, market-ready prototypes: Vacuum casting is an excellent choice, delivering superior aesthetics and material properties compared to 3D printing.

- If your primary focus is a small production run (20-200 units): This is the sweet spot for vacuum casting, as creating multiple silicone molds is still far cheaper than tooling for injection molding.

- If your primary focus is high-volume manufacturing (1,000+ units): Vacuum casting is not a viable option; its cost and speed limitations make injection molding the only practical choice.

- If your primary focus is mechanical strength or high-temperature performance: You should use CNC machining for metal parts or choose a manufacturing process that uses true engineering-grade thermoplastics.

Ultimately, vacuum casting is a specialized tool designed to bridge the critical gap between a single prototype and full-scale production.

Summary Table:

| Limitation | Description | Impact |

|---|---|---|

| Material Restrictions | Limited to polyurethane resins; cannot use high-temperature materials or metals. | Parts have lower thermal resistance and may not mimic all production plastics accurately. |

| Material Shrinkage | Shrinkage rate of 0.1% to 0.2% during curing. | Can affect dimensional accuracy, especially in parts with tight tolerances. |

| Limited Mold Lifespan | Silicone molds degrade after 20-50 uses. | Not suitable for mass production; increases cost-per-part for larger volumes. |

| Slow Process and Low Scalability | Manual, batch-based process with curing times from under an hour to several hours. | Inefficient for high-volume runs; cost-per-part remains high. |

Need advanced thermal solutions for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, overcoming material and temperature limitations. Contact us today to discuss how our tailored solutions can enhance your research and production processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion