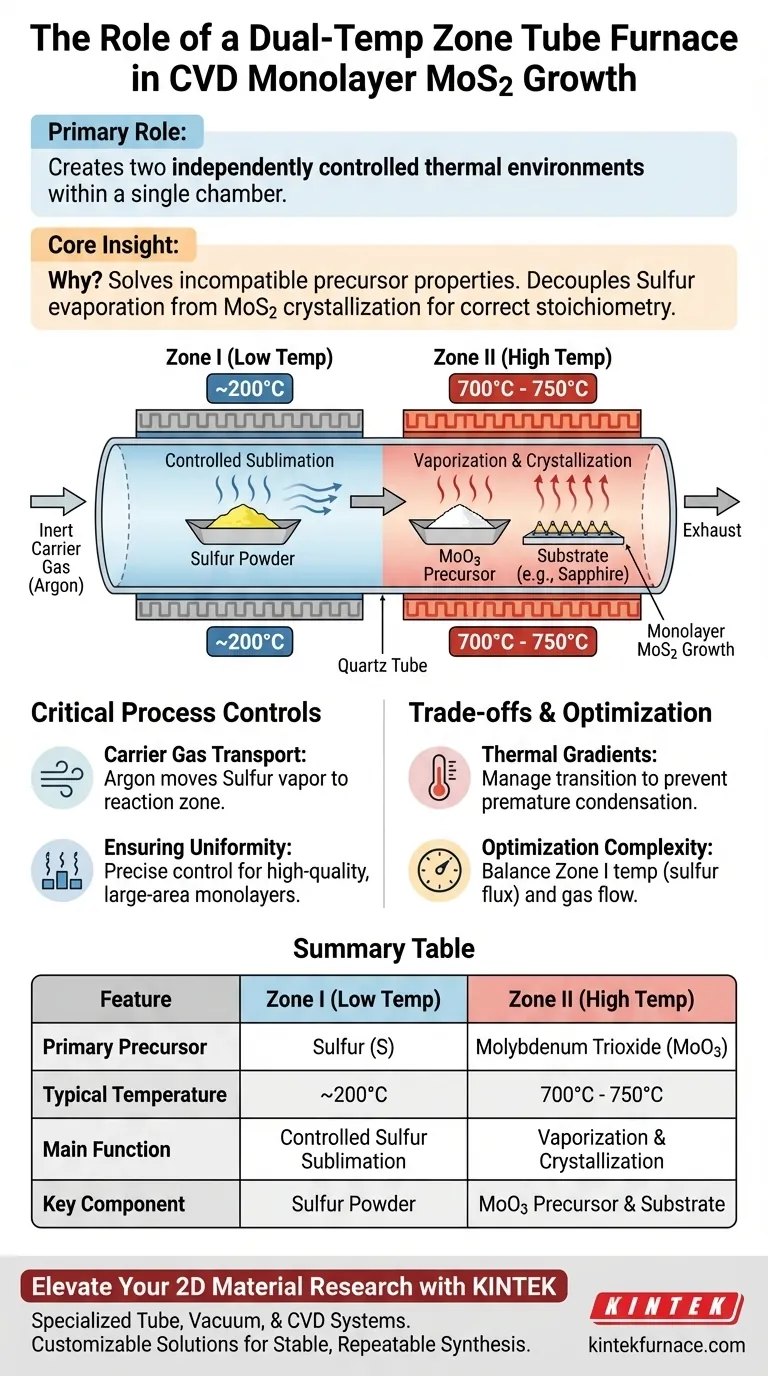

The primary role of a dual-temperature zone tube furnace in CVD is to create two distinct, independently controlled thermal environments within a single reaction chamber. This configuration is essential because the two precursor materials—Sulfur and Molybdenum Trioxide (MoO3)—have vastly different sublimation points. By maintaining a low-temperature zone (approximately 200°C) for sulfur and a high-temperature zone (approximately 700°C) for the molybdenum source and substrate, the system ensures stable vapor generation and facilitates the precise chemical reaction required for monolayer growth.

Core Insight: The dual-zone configuration solves the problem of incompatible precursor properties. It allows you to decouple the evaporation rate of the sulfur from the crystallization temperature of the molybdenum disulfide, ensuring the correct stoichiometric ratio reaches the substrate.

The Mechanics of Dual-Zone CVD

Managing Disparate Sublimation Points

The synthesis of Molybdenum Disulfide (MoS2) requires two solid precursors: Sulfur powder and Molybdenum Trioxide (MoO3) powder.

These materials cannot be processed at the same temperature. Sulfur sublimates at a relatively low temperature, while MoO3 requires significantly higher heat to vaporize and react.

The Low-Temperature Zone (Zone I)

This zone is typically set to approximately 200°C (though specific protocols may vary).

Its sole purpose is the controlled sublimation of the sulfur powder. By isolating the sulfur in this cooler zone, the furnace prevents rapid, uncontrolled evaporation that would occur if the sulfur were exposed to the high reaction temperatures immediately.

The High-Temperature Zone (Zone II)

This zone is maintained at a much higher temperature, typically around 700°C to 750°C.

This zone houses both the MoO3 precursor and the deposition substrate (often sapphire or silica). The high heat triggers the vaporization of MoO3 and provides the thermal energy necessary for the chemical reaction and subsequent crystallization of MoS2 on the substrate surface.

Critical Process Controls

Transport via Carrier Gas

While the furnace provides the heat, an inert carrier gas (typically high-purity Argon) provides the transport mechanism.

The gas flows from the low-temperature zone to the high-temperature zone. It carries the sulfur vapor downstream, where it mixes with the MoO3 vapor to react at the substrate site.

Ensuring Uniformity and Quality

The precise control of the two temperature zones ensures that precursor vapors arrive at the substrate at specific, controlled rates.

This stability is what enables the growth of high-quality, large-area monolayers with uniform atomic thickness and triangular morphology. Without this balance, the growth results in uneven, bulk, or low-quality crystals.

Understanding the Trade-offs

Sensitivity to Thermal Gradients

While dual-zone furnaces offer precision, they introduce complexity regarding the thermal gradient between zones.

If the transition between the 200°C zone and the 700°C zone is not managed correctly, vapors may condense prematurely in the cooler region between the heaters. This can starve the reaction zone of necessary precursors.

Optimization Complexity

Dual-zone systems require more parameters to be optimized compared to single-zone systems.

You must balance the temperature of Zone I (which dictates sulfur flux) against the flow rate of the carrier gas. If Zone I is too hot, sulfur is exhausted too quickly; if it is too cool, the reaction becomes sulfur-deficient, leading to poor film quality.

Making the Right Choice for Your Goal

The dual-zone tube furnace is the industry standard for research-grade MoS2 synthesis. How you configure it depends on your specific output requirements.

- If your primary focus is Monolayer Purity: Prioritize the precision of the low-temperature zone to prevent sulfur oversaturation, which can lead to multilayer growth.

- If your primary focus is Crystal Size: Focus on optimizing the high-temperature zone (700°C+) to encourage slower, more ordered thermodynamic growth on the substrate.

Summary: The dual-temperature zone furnace transforms a complex chemical incompatibility into a controllable variable, acting as the fundamental enabler for growing high-quality 2D materials.

Summary Table:

| Feature | Zone I (Low Temp) | Zone II (High Temp) |

|---|---|---|

| Primary Precursor | Sulfur (S) | Molybdenum Trioxide (MoO3) |

| Typical Temperature | ~200°C | 700°C - 750°C |

| Main Function | Controlled Sulfur Sublimation | Vaporization & Crystallization |

| Key Component | Sulfur Powder | MoO3 Precursor & Substrate |

Elevate Your 2D Material Research with KINTEK

Precise thermal gradients are the secret to high-quality monolayer growth. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems designed specifically for the rigorous demands of material science.

Whether you need a standard dual-zone configuration or a fully customizable high-temp furnace tailored to your unique research needs, our team provides the technical expertise to ensure your synthesis is stable and repeatable.

Ready to optimize your CVD process?

Contact us today to find your custom furnace solution!

Visual Guide

References

- Krishna Rani Sahoo, Tharangattu N. Narayanan. Vanadium Doped Magnetic MoS<sub>2</sub> Monolayers of Improved Electrical Conductivity as Spin‐Orbit Torque Layer. DOI: 10.1002/adfm.202502408

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What core physical conditions does a tube furnace provide in the two-step synthesis of WS2? Master Film Growth

- How does a programmable tube furnace facilitate Al/SiC material transformation? Precision Heat for Ceramic Coatings

- Why is a dual-zone tube furnace necessary for MnO2/CF phosphorization? Master CVD Synthesis with Precision Control

- What is the core function of a dual-zone tube CVD system? Precision Synthesis for MnS Nanosheets

- How does a dual-zone tube furnace facilitate Bi4I4 single crystal growth? Master Precision Thermal Gradient Control