The primary function of a vacuum sealed tube furnace in this context is to act as a precision thermal reactor that facilitates the phase transformation of red phosphorus into black phosphorus. It creates a stable high-temperature environment within a vacuum-sealed quartz tube and executes a specific cooling program to drive crystal growth.

The furnace ensures the success of the synthesis not merely by heating the material, but by controlling the rate of cooling. By maintaining a vacuum and slowly lowering the temperature from 923 K to 773 K, the system allows mineralizing agents to effectively convert red phosphorus into high-crystallinity black phosphorus.

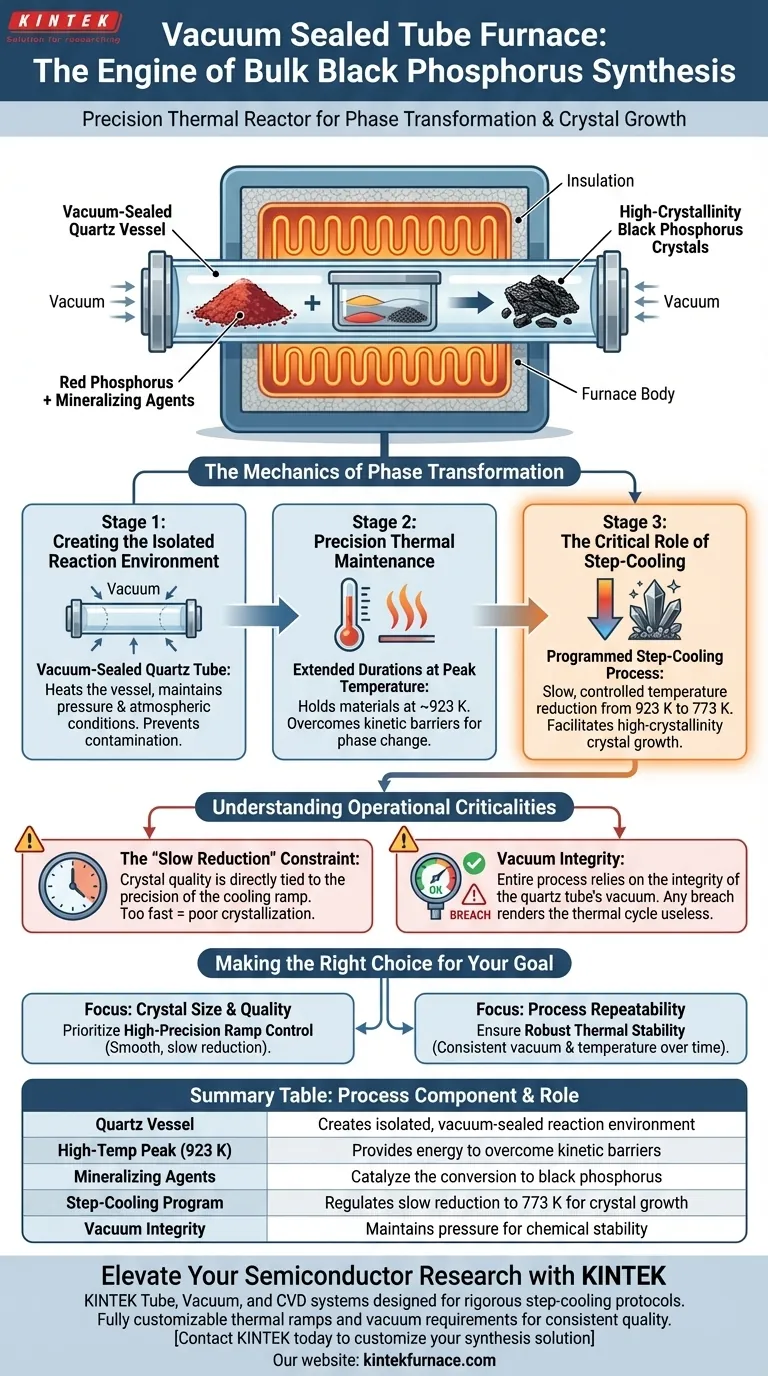

The Mechanics of Phase Transformation

Creating the Isolated Reaction Environment

The foundation of this process is the vacuum-sealed quartz tube.

The furnace does not act directly on the phosphorus; rather, it heats the quartz vessel. This isolation is critical for maintaining the specific pressure and atmospheric conditions required for the reaction.

Inside this vacuum, the red phosphorus is exposed to mineralizing agents. The sealed environment ensures that these agents can catalyze the phase change without external contamination or atmospheric interference.

Precision Thermal Maintenance

The synthesis of bulk Black Phosphorus is not an instantaneous event; it requires extended durations of heat.

The tube furnace provides the necessary thermal stability to hold materials at peak temperatures (starting around 923 K). This prolonged exposure energy overcomes the kinetic barriers associated with changing the material's atomic structure.

The Critical Role of Step-Cooling

The most distinct function of the furnace in this specific synthesis is the execution of a programmed step-cooling process.

Unlike processes that simply heat and hold, this method requires a slow, controlled reduction in temperature. The furnace regulates the decline from 923 K down to 773 K.

It is during this slow cooling phase that the high-crystallinity black phosphorus crystals actually grow.

Understanding Operational Criticalities

While the tube furnace is a versatile tool, its application in black phosphorus synthesis relies on strict adherence to thermal profiles.

The "Slow Reduction" Constraint The quality of the final crystal is directly tied to the precision of the cooling ramp. A furnace that cools too quickly, or fluctuates during the step-down process, will likely result in poor crystallization or incomplete phase transformation.

Vacuum Integrity The process relies entirely on the integrity of the quartz tube's vacuum. While the furnace provides the heat, any breach in the vacuum seal compromises the pressure conditions required for the mineralizing agents to function, rendering the thermal cycle useless.

Making the Right Choice for Your Goal

To achieve the best results in black phosphorus synthesis, focus on the programmable features of your equipment.

- If your primary focus is Crystal Size and Quality: Prioritize a furnace with high-precision ramp control to ensure the temperature reduction between 923 K and 773 K is as smooth and slow as possible.

- If your primary focus is Process Repeatability: Ensure your furnace offers robust thermal stability to maintain the exact vacuum and temperature conditions over the extended durations required for synthesis.

Mastering the use of the vacuum sealed tube furnace allows you to turn a volatile raw material into a stable, high-performance semiconductor.

Summary Table:

| Process Component | Role in Synthesis |

|---|---|

| Quartz Vessel | Creates an isolated, vacuum-sealed reaction environment |

| High-Temp Peak (923 K) | Provides energy to overcome kinetic barriers for phase change |

| Mineralizing Agents | Catalyze the conversion of red phosphorus to black phosphorus |

| Step-Cooling Program | Regulates the slow reduction to 773 K for crystal growth |

| Vacuum Integrity | Maintains pressure conditions required for chemical stability |

Elevate Your Semiconductor Research with KINTEK

Precision phase transformation requires uncompromising thermal stability. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed to handle the rigorous step-cooling protocols essential for high-crystallinity Black Phosphorus synthesis.

Backed by expert R&D and manufacturing, our lab high-temp furnaces are fully customizable to your specific cooling ramps and vacuum requirements. Ensure consistent repeatability and superior crystal quality in every batch.

Contact KINTEK today to customize your synthesis solution

Visual Guide

References

- Jian Feng, Ke Xu. Effectively Enhanced Photocatalytic Performance of BP/BiOBr 2D/2D Z-Scheme Heterojunction. DOI: 10.3390/molecules30030538

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a horizontal dual-zone tube furnace facilitate WSe2 CVT growth? Precision Thermal Gradient Control

- How do controlled tube furnace systems achieve atmosphere regulation? Study Zirconia Phase Transformation Laws

- How does a tube furnace contribute to the synthesis of electrocatalysts from hydrochar? Precision Thermal Engineering

- What is the significance of the gas path control system in a laboratory tube furnace during activated carbon synthesis?

- What is the function of a tube furnace in pRF preparation? Optimize Carbonization & Conductivity

- What is the role of a tube sintering furnace during the activation of carbon materials? Expert Guide to CO2 Activation

- How does a tube furnace facilitate the structural stabilization of lignin? Mastering Lignin-to-Carbon Transformation

- Why are controlled atmosphere and vacuum operations important for tube furnaces? Protect Materials and Enable Precision Reactions