In essence, a Plasma-Enhanced Chemical Vapor Deposition (PECVD) configuration is a specialized vacuum system designed to grow thin films on a substrate. It primarily consists of a reaction chamber containing parallel electrodes, where one is powered to generate a plasma. This plasma breaks down precursor gases, which then react and deposit as a solid film onto the substrate, all at significantly lower temperatures than traditional Chemical Vapor Deposition (CVD).

The core principle of a PECVD configuration is its use of radio-frequency (RF) plasma to supply the energy for chemical reactions. This allows for high-quality film deposition on temperature-sensitive materials that would be damaged by the high heat of conventional CVD processes.

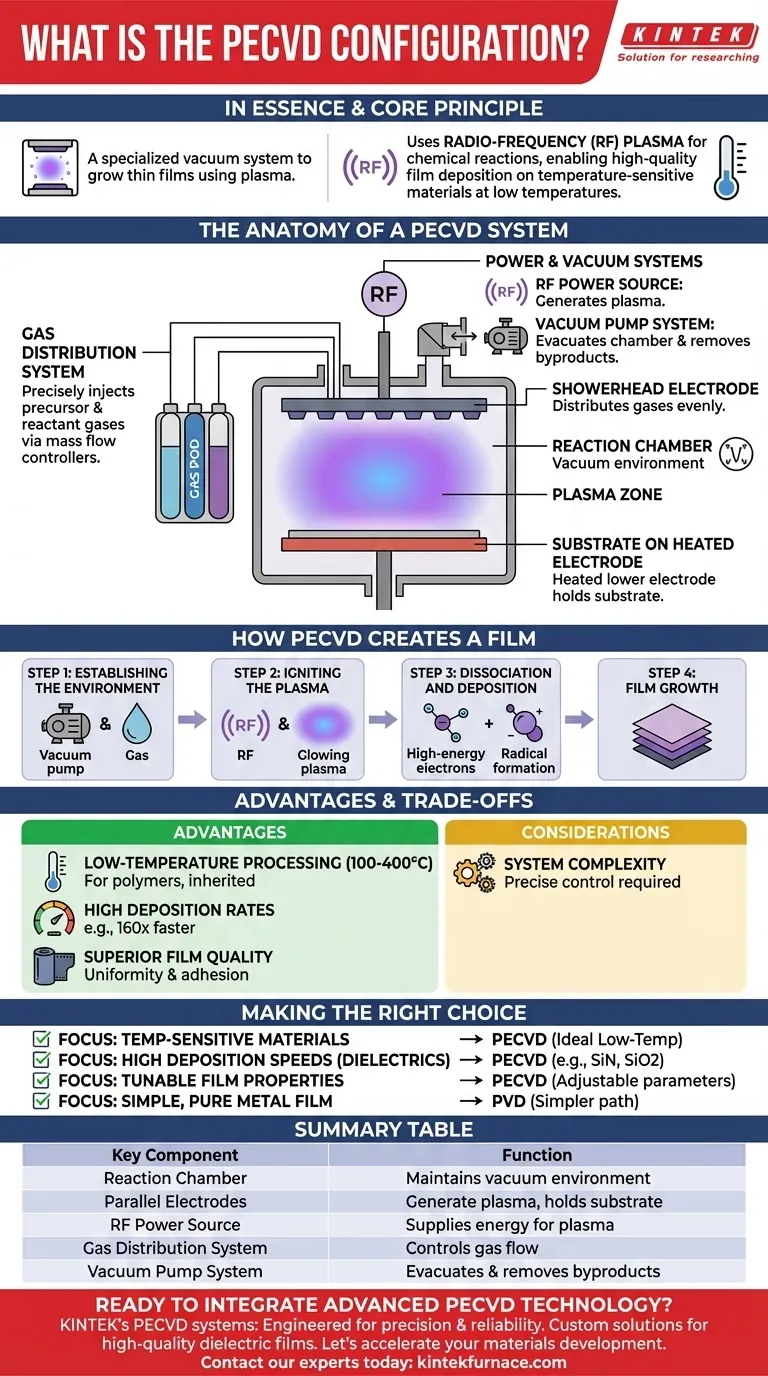

The Anatomy of a PECVD System

A PECVD system is an assembly of several critical subsystems working in concert to control a complex chemical process within a vacuum.

The Reaction Chamber and Electrodes

The process takes place within a vacuum chamber. Inside, a parallel-plate reactor is the most common setup. This consists of two parallel electrodes.

The substrate, such as a silicon wafer, is placed on the lower electrode, which is often heated to a controlled, moderate temperature.

The upper electrode is connected to a power source and acts as the plasma generator. This electrode is frequently designed as a "showerhead" to ensure precursor gases are distributed evenly across the substrate, which is critical for achieving film uniformity.

The Gas Distribution System

A sophisticated gas delivery system, often a multi-line gas pod, uses mass flow controllers to precisely inject precursor and reactant gases into the chamber. The composition and flow rate of these gases are key parameters for controlling the final properties of the deposited film.

The Power and Vacuum Systems

An RF (Radio Frequency) power source is applied to the upper electrode to excite the gases and create the plasma. The plasma is a state of ionized gas containing a mix of ions, electrons, and highly reactive neutral species.

A vacuum pump system is used to evacuate the chamber to a low base pressure before the process begins and to continuously remove excess gas and byproducts during deposition.

How PECVD Creates a Film

The deposition process is a carefully orchestrated sequence of physical and chemical events.

Step 1: Establishing the Environment

First, the chamber is pumped down to a high vacuum. Then, a controlled flow of precursor and reactant gases is introduced, raising the pressure to the desired processing level.

Step 2: Igniting the Plasma

RF power is applied to the top electrode. This energy strips electrons from the gas molecules, creating the glowing, chemically reactive plasma that gives the process its name.

Step 3: Dissociation and Deposition

Within the plasma, the high-energy electrons collide with the gas molecules, breaking them down into smaller, highly reactive fragments (radicals). These radicals diffuse through the chamber and adsorb onto the surface of the substrate.

Step 4: Film Growth

On the substrate surface, these reactive species undergo chemical reactions, forming a solid, stable thin film. The continuous supply of radicals from the plasma allows the film to grow layer by layer.

Understanding the Advantages and Trade-offs

The unique configuration of PECVD provides distinct benefits but also introduces complexity.

Advantage: Low-Temperature Processing

This is the primary benefit of PECVD. By using plasma energy instead of purely thermal energy, deposition can occur at temperatures (typically 100-400°C) low enough for plastics, polymers, and other temperature-sensitive materials.

Advantage: High Deposition Rates

PECVD can be significantly faster than other methods. For example, silicon nitride deposition can be up to 160 times faster than with conventional high-temperature CVD.

Advantage: Superior Film Quality

Films deposited by PECVD are known for their high quality. They exhibit excellent uniformity, strong adhesion to the substrate, and a reduced likelihood of pinholes or cracking compared to other techniques. They also provide excellent coverage on complex, three-dimensional surfaces.

Consideration: System Complexity

While powerful, the PECVD process is more complex than a purely physical method like PVD. It requires precise control over gas chemistry, flow rates, pressure, and plasma power to achieve repeatable results. The configuration itself, with its RF power systems and complex gas handling, is inherently more intricate.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the material you are depositing and the substrate you are using.

- If your primary focus is depositing on temperature-sensitive materials: PECVD is the ideal choice due to its low-temperature operation.

- If your primary focus is achieving very high deposition speeds for dielectrics: PECVD is a leading candidate for materials like silicon nitride and silicon dioxide.

- If your primary focus is creating films with tunable properties: PECVD offers excellent control over film characteristics by adjusting gas mixtures and plasma parameters.

- If your primary focus is depositing a simple, pure metal film: Physical Vapor Deposition (PVD) may offer a simpler and more direct path.

Understanding this configuration empowers you to select the precise tool needed to transform raw gases into advanced material films.

Summary Table:

| Key Component | Function |

|---|---|

| Reaction Chamber | Maintains a vacuum environment for the deposition process. |

| Parallel Electrodes | Generate plasma; the substrate is placed on the lower, heated electrode. |

| RF Power Source | Supplies energy to create the reactive plasma from precursor gases. |

| Gas Distribution System | Precisely controls the flow of precursor and reactant gases into the chamber. |

| Vacuum Pump System | Evacuates the chamber and removes process byproducts. |

Ready to integrate advanced PECVD technology into your lab?

KINTEK's PECVD systems are engineered for researchers and engineers who demand precision and reliability. Leveraging our exceptional in-house R&D and manufacturing, we deliver robust solutions for depositing high-quality dielectric films on temperature-sensitive substrates.

Our systems are backed by deep customization capabilities to meet your unique experimental requirements. Let's discuss how a KINTEK PECVD system can accelerate your materials development.

Contact our experts today to explore your specific needs

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What forms of energy can be applied in CVD to initiate chemical reactions? Explore Heat, Plasma, and Light for Optimal Thin Films

- What are the main advantages of PECVD tube furnaces compared to CVD tube furnaces? Lower Temp, Faster Deposition, and More