The primary advantage of PECVD over conventional CVD tube furnaces is its ability to deposit high-quality thin films at significantly lower temperatures. By using plasma instead of high heat to drive the chemical reaction, PECVD opens up a range of benefits related to speed, energy efficiency, cost, and the types of materials you can work with. This fundamental difference is the source of nearly every other advantage the technology offers.

While both conventional CVD and PECVD are used for thin-film deposition, they operate on different principles. CVD relies on high thermal energy, whereas PECVD uses lower-temperature plasma. This makes PECVD a faster, more energy-efficient, and more versatile process for many modern applications.

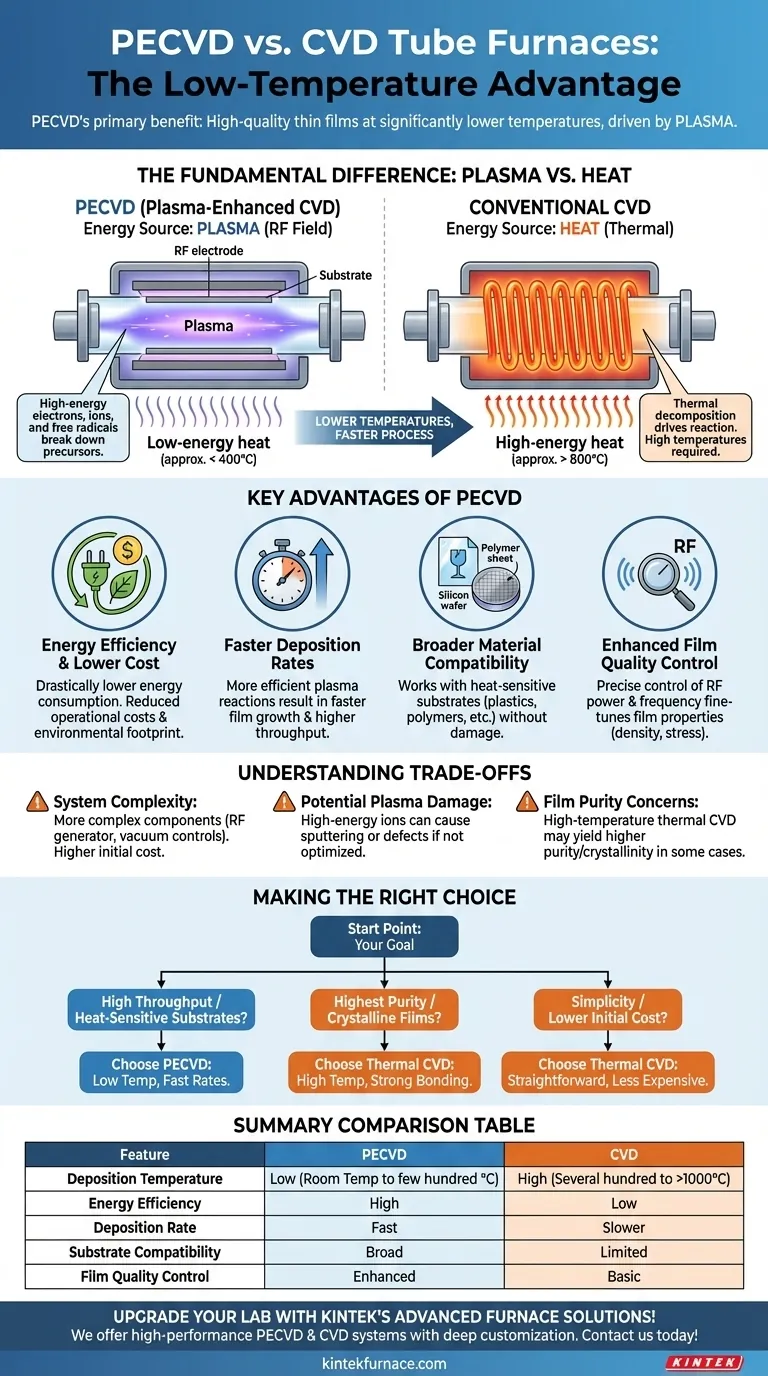

The Fundamental Difference: Plasma vs. Heat

To understand the advantages, you must first grasp the core operational difference between the two technologies. The method of energy input dictates the entire process.

How Conventional CVD Works

A traditional Chemical Vapor Deposition (CVD) process is purely thermal. It requires very high temperatures, often from several hundred to over a thousand degrees Celsius, to give precursor gas molecules enough energy to react and deposit onto a substrate.

The furnace's sole purpose is to generate and sustain this intense heat uniformly. The reaction is driven entirely by thermal decomposition.

How PECVD Works

Plasma-Enhanced Chemical Vapor Deposition (PECVD) uses a different energy source. Instead of relying solely on heat, it introduces energy via a radio frequency (RF) field, which ionizes the gases into a state of matter called plasma.

This plasma contains high-energy electrons, ions, and free radicals. These energized particles, not high temperatures, are what break apart the precursor gas molecules and drive the deposition reaction. This allows the process to run at much lower temperatures, from room temperature up to a few hundred degrees Celsius.

Key Advantages of PECVD Operation

The ability to operate at low temperatures creates several critical downstream advantages for manufacturing and research.

Superior Energy Efficiency and Lower Cost

Because PECVD does not require a furnace to reach extremely high temperatures, its overall energy consumption is drastically lower.

This directly translates to reduced operational costs and a smaller environmental footprint. Lower temperatures mean less energy spent per run and less wear on furnace components.

Faster Deposition Rates

The plasma-driven reactions in a PECVD system are often more efficient and rapid than their thermal counterparts.

This results in faster film growth and higher sample throughput, which is a major cost and time advantage in production environments.

Broader Material and Substrate Compatibility

This is arguably one of the most significant benefits. The high temperatures of conventional CVD can damage or destroy heat-sensitive substrates, such as plastics, polymers, or certain semiconductor devices.

PECVD's low-temperature process makes it possible to deposit high-quality films on these materials without causing thermal damage, vastly expanding its range of applications.

Enhanced Film Quality Control

In a PECVD system, you have more variables to control the deposition. Beyond temperature and gas flow, you can precisely adjust the RF power and frequency.

These additional control levers allow for fine-tuning of the plasma environment, which in turn influences film properties like density, stress, and chemical composition.

Understanding the Trade-offs

While powerful, PECVD is not a universal replacement for all CVD processes. Understanding its limitations is key to making an objective decision.

System Complexity

A PECVD furnace is inherently more complex than a standard thermal CVD furnace. It requires an RF power generator, an impedance-matching network, and more sophisticated vacuum system controls.

This added complexity can increase the initial equipment cost and introduce more potential points of maintenance or failure compared to a simpler thermal system.

Potential for Plasma-Induced Damage

While the low temperature is gentle on substrates, the high-energy ions within the plasma can sometimes cause physical damage (sputtering) or create defects in the growing film or the substrate itself.

Controlling the plasma process to achieve a high deposition rate without causing damage is a key challenge that requires process expertise.

Film Purity Concerns

In some specific applications, high-temperature thermal CVD can produce films with higher purity or better crystallinity. The intense heat can be more effective at driving off contaminants, like hydrogen, which can sometimes become incorporated into films grown via PECVD.

Making the Right Choice for Your Application

The choice between PECVD and conventional CVD is a strategic one that hinges entirely on your specific goals and constraints.

- If your primary focus is high-throughput production or working with heat-sensitive substrates: PECVD is almost always the superior choice due to its low-temperature operation and fast deposition rates.

- If your primary focus is depositing highly pure, crystalline films on robust substrates where film quality is paramount: High-temperature thermal CVD may still be necessary to achieve the required material structure.

- If your primary focus is simplicity and lower initial equipment cost for foundational research: A conventional thermal CVD tube furnace can be a more straightforward and less expensive entry point.

Ultimately, selecting the right technology depends on a clear understanding of your material requirements, substrate limitations, and production goals.

Summary Table:

| Advantage | PECVD | CVD |

|---|---|---|

| Deposition Temperature | Low (room temp to a few hundred °C) | High (several hundred to over 1000°C) |

| Energy Efficiency | High (lower energy use) | Low (high energy consumption) |

| Deposition Rate | Fast | Slower |

| Substrate Compatibility | Broad (works with heat-sensitive materials) | Limited (can damage sensitive substrates) |

| Film Quality Control | Enhanced (via RF power and frequency) | Basic (via temperature and gas flow) |

Upgrade your lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance PECVD and CVD tube furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether for high-throughput production, heat-sensitive substrates, or pure film deposition. Contact us today to discuss how our tailored solutions can enhance your research and efficiency!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition