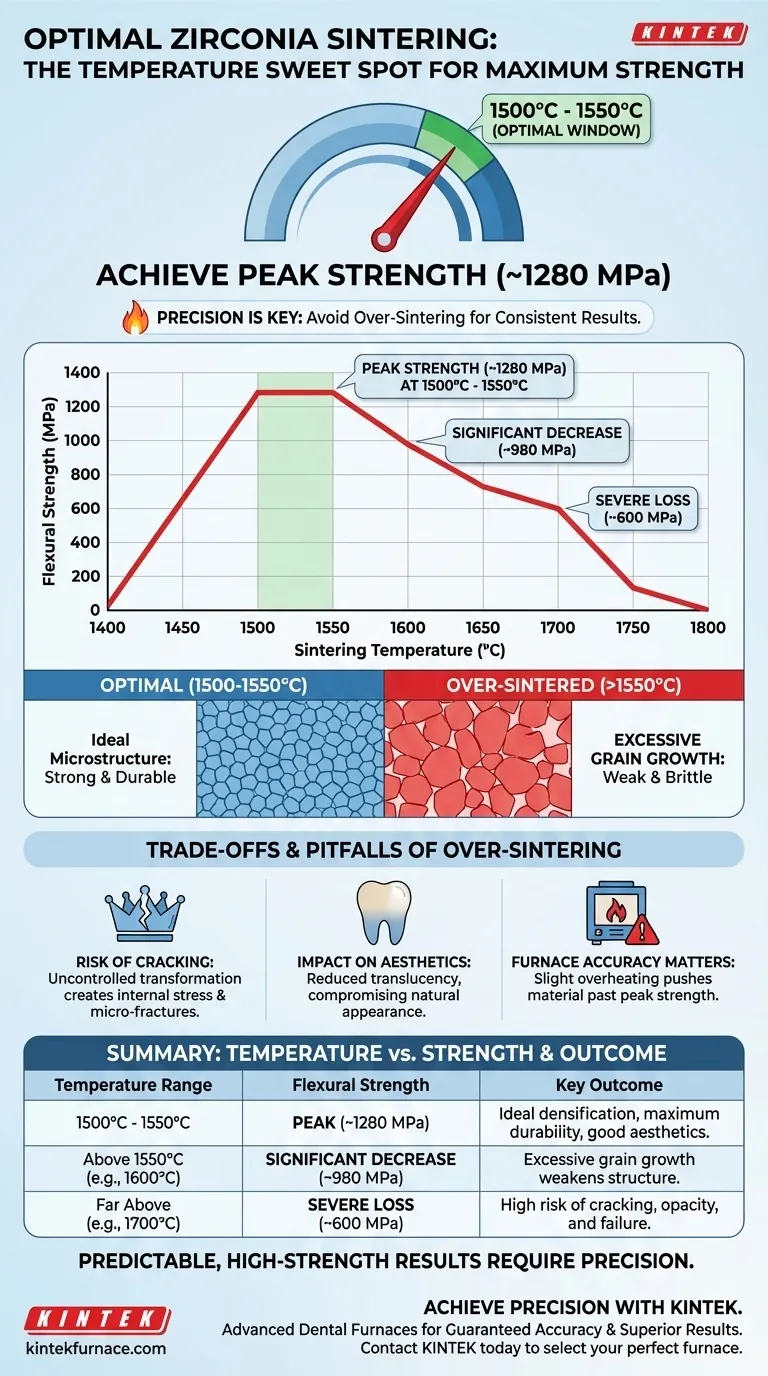

To achieve maximum flexural strength, the optimal sintering temperature for yttria-stabilized zirconia is a precise window between 1500°C and 1550°C. Sintering above this range causes a significant and rapid decline in strength. For example, strength can drop from approximately 1280 MPa at 1500°C to only 980 MPa if the temperature is increased to 1600°C.

The goal of sintering zirconia is not to use the highest possible heat, but to achieve a specific temperature sweet spot. Exceeding this optimal range initiates excessive grain growth, which fundamentally weakens the material's structure and compromises both its strength and aesthetics.

The Critical Relationship Between Temperature and Strength

Understanding how temperature affects zirconia's microstructure is key to producing strong, reliable restorations. The process is a balance between achieving full density and preventing structural degradation.

The Peak Strength Window

The ideal physical and mechanical properties of zirconia are achieved at approximately 1550°C. Within the 1500°C to 1550°C range, the material undergoes the necessary densification and crystallization to become strong and durable.

The Point of Diminishing Returns

Sintering above this optimal window leads to a sharp decrease in strength. The material's integrity begins to degrade quickly as the temperature rises.

Data clearly shows that strength falls from a peak of ~1280 MPa at 1500°C to ~980 MPa at 1600°C. If the temperature reaches 1700°C, the strength can plummet to as low as ~600 MPa, a reduction of over 50%.

Why Higher Temperatures Weaken Zirconia

This strength reduction is caused by uncontrolled grain growth within the zirconia's crystalline structure. Excessive heat causes the grains to enlarge beyond their optimal size, leading to lowered material stability and creating internal stresses that weaken the final restoration.

Understanding the Trade-offs and Pitfalls

Pushing the temperature beyond the recommended range introduces significant risks that extend beyond just a loss of strength. It can negatively impact the entire outcome of the restoration.

The Risk of Cracking

Over-sintering leads to uncontrolled material transformation. This instability can introduce micro-fractures or even cause catastrophic cracking of the restoration during or after the cooling process.

The Impact on Aesthetics

Excessively high temperatures also have a negative effect on the material's translucency. Over-firing can make the zirconia appear more opaque, compromising the esthetic properties required for a natural-looking final result.

The Importance of Furnace Accuracy

Given the narrow window for optimal sintering, the accuracy and calibration of your dental furnace are paramount. A furnace that runs even slightly hotter than its displayed temperature can inadvertently push the zirconia past its peak strength, leading to inconsistent and inferior results.

Making the Right Choice for Your Goal

Your sintering protocol should be guided by a clear understanding of these material principles to ensure predictable outcomes.

- If your primary focus is maximum strength and durability: Target the 1500°C to 1550°C range with precision, and ensure your furnace is calibrated regularly to avoid over-shooting this critical window.

- If your primary focus is balancing strength with aesthetics: Adhering to the 1550°C upper limit is essential, as exceeding it compromises both the flexural strength and the final translucency of the restoration.

Mastering zirconia sintering is about precision, not brute force, ensuring predictable and superior results for every case.

Summary Table:

| Temperature Range | Impact on Flexural Strength | Key Outcome |

|---|---|---|

| 1500°C - 1550°C (Optimal) | Peak Strength (~1280 MPa) | Ideal densification, maximum durability, and good aesthetics. |

| Above 1550°C (e.g., 1600°C) | Significant Decrease (~980 MPa) | Excessive grain growth begins, weakening the structure. |

| Far Above Range (e.g., 1700°C) | Severe Loss (~600 MPa) | High risk of cracking, opacity, and structural failure. |

Achieve Predictable, High-Strength Zirconia Restorations with KINTEK

Mastering the precise temperature control required for optimal zirconia sintering is critical for the success of your dental lab. Inconsistent furnace performance can lead to weakened restorations, increased failure rates, and unhappy clients.

KINTEK's advanced dental furnaces are engineered for the precision you need. Our Muffle and Vacuum furnaces deliver the accurate, uniform heating required to consistently hit the 1500-1550°C sweet spot, case after case.

Why choose KINTEK for your sintering needs?

- Guaranteed Accuracy: Avoid the risks of over-sintering with our precisely calibrated heating elements and advanced controllers.

- Superior Results: Achieve maximum flexural strength and perfect aesthetics for every restoration.

- Customizable Solutions: Our expert R&D team can tailor a furnace system to fit your lab's unique workflow and volume requirements.

Stop leaving your results to chance. Ensure every zirconia case reaches its maximum potential strength and beauty.

Contact KINTEK today for a consultation and let our experts help you select the perfect furnace for predictable, high-performance sintering.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations