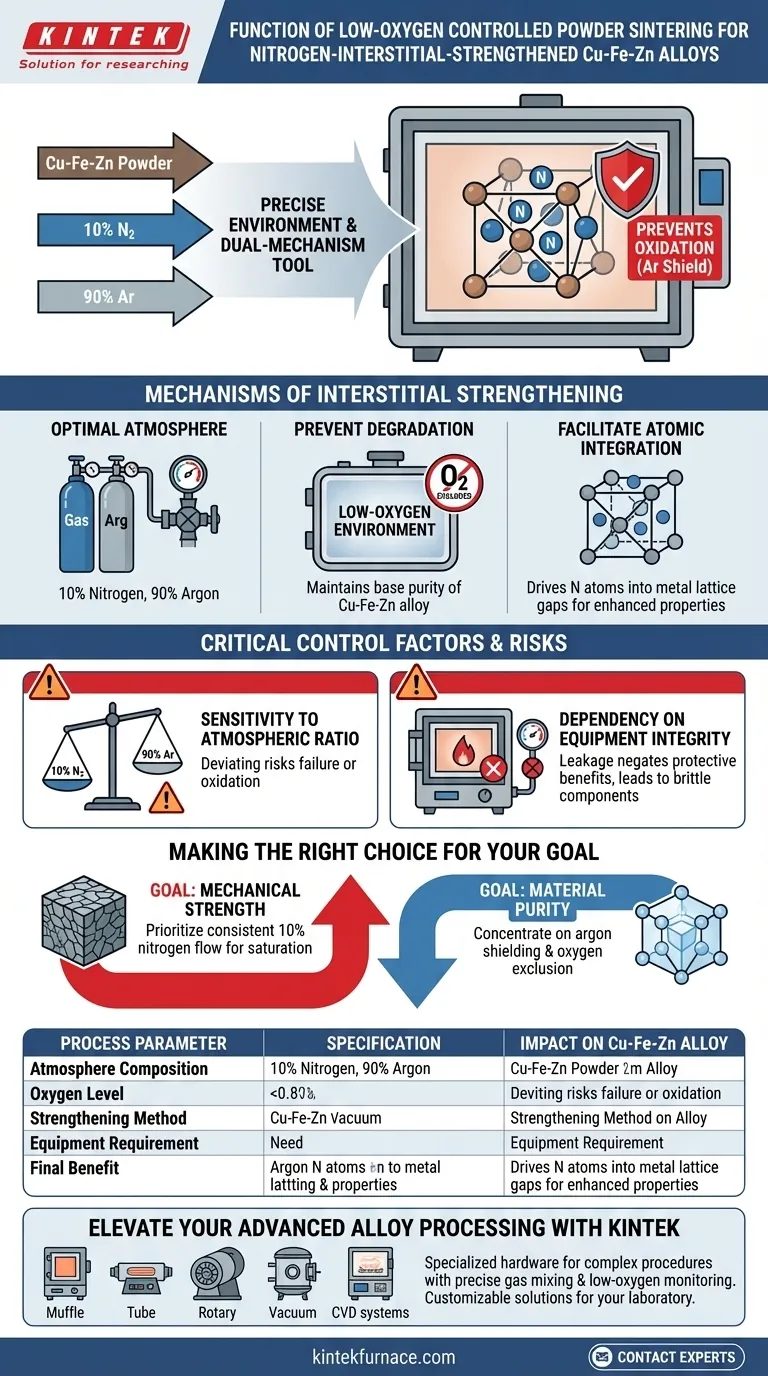

The primary function of the low-oxygen controlled powder sintering process is to create a precise environment that enables interstitial nitrogen solid solution. By utilizing a specific atmosphere of 10% Nitrogen (N2) and 90% Argon (Ar), this process simultaneously prevents raw material oxidation and facilitates the integration of nitrogen atoms into the metal lattice, resulting in significant mechanical strengthening.

By strictly controlling the atmospheric composition, this process acts as a dual-mechanism tool: it protects the Cu-Fe-Zn alloy from high-temperature degradation while actively utilizing nitrogen atoms to reinforce the material's internal structure.

Mechanisms of Interstitial Strengthening

The effectiveness of this sintering process relies on the manipulation of the atomic environment. It moves beyond simple heating to actively alter the chemical interaction between the gas phase and the solid metal.

Creating the Optimal Atmosphere

The process operates under a rigorously defined mixed atmosphere. This mixture consists of 10% Nitrogen and 90% Argon. This specific ratio is calculated to balance inert protection with active strengthening elements.

Preventing Material Degradation

Standard high-temperature sintering often exposes metal powders to oxygen, leading to structural weaknesses. This controlled process creates a low-oxygen environment that prevents excessive oxidation of the metal raw materials. This ensures the base purity of the Cu-Fe-Zn alloy is maintained throughout the thermal cycle.

Facilitating Atomic Integration

The core objective is to drive nitrogen atoms into the metal lattice gaps. The controlled atmosphere facilitates the effective entry of these atoms into the interstitial spaces of the crystal structure. This atomic "stuffing" is the fundamental driver behind the enhanced mechanical properties of the alloy.

Critical Control Factors and Risks

While this process offers significant strengthening benefits, it relies heavily on precision. The "trade-off" for superior mechanical properties is the requirement for exacting process control.

Sensitivity to Atmospheric Ratio

The success of the process hinges on the 10% N2 / 90% Ar balance. Deviating from this mixture risks failing to achieve the necessary solid solution state or allowing oxidation to compromise the metal.

Dependency on Equipment Integrity

To maintain a low-oxygen environment, the sintering equipment must be capable of rigorous sealing and monitoring. Any leakage or inability to sustain the specific gas pressure negates the protective benefits, leading to oxidized, brittle components rather than strengthened ones.

Making the Right Choice for Your Goal

To successfully implement this process for Cu-Fe-Zn alloys, you must align your processing parameters with your desired material outcomes.

- If your primary focus is mechanical strength: Prioritize the consistency of the 10% nitrogen flow to maximize the saturation of nitrogen atoms within the lattice gaps.

- If your primary focus is material purity: Concentrate on the integrity of the argon shielding and oxygen exclusion to prevent surface or internal oxidation of the raw materials.

Mastering the precise balance of this atmospheric control is the defining factor in producing high-performance nitrogen-interstitial-strengthened alloys.

Summary Table:

| Process Parameter | Specification / Mechanism | Impact on Cu-Fe-Zn Alloy |

|---|---|---|

| Atmosphere Composition | 10% N2 + 90% Ar | Balances inert protection with reactive strengthening |

| Oxygen Level | Ultra-Low (Controlled) | Prevents raw material oxidation and degradation |

| Strengthening Method | Interstitial Solid Solution | Drives nitrogen atoms into metal lattice gaps |

| Equipment Requirement | Rigorous Sealing & Monitoring | Ensures atmospheric integrity and material purity |

| Final Benefit | Mechanical Strengthening | Significantly enhanced structural properties |

Elevate Your Advanced Alloy Processing with KINTEK

Precise atmospheric control is the difference between a brittle component and a high-performance alloy. KINTEK provides the specialized hardware necessary for complex procedures like nitrogen-interstitial strengthening.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized with precise gas mixing and low-oxygen monitoring to meet your unique sintering needs. Whether you are developing Cu-Fe-Zn alloys or other advanced materials, our high-temperature furnaces provide the stability and purity your research demands.

Ready to optimize your sintering environment? Contact our experts today to find the perfect customizable solution for your laboratory.

Visual Guide

References

- Xiaohui Qiu, Jianda Zhou. Interstitial N‐Strengthened Copper‐Based Bioactive Conductive Dressings Combined with Electromagnetic Fields for Enhanced Wound Healing. DOI: 10.1002/adhm.202501303

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the relationship between temperature and furnace atmosphere effectiveness? Master Heat Treatment Control

- Which industries commonly use atmosphere furnaces? Unlock Precision in High-Temp Processing

- What factors should be considered when purchasing an inert oven? Ensure Optimal Performance and Safety

- What industries commonly use retort furnaces and for what purposes? Unlock High-Purity Thermal Processing

- What is a brazing furnace? Achieve Superior, Oxidation-Free Metal Joining

- What are the technical advantages of a Zero-reforming Vertical Furnace? Revolutionize Green DRI Production Today

- What are the main methods for containing furnace atmospheres? Choose the Best for Your Heat Treatment

- Why is an industrial calcination furnace required to process carbon-supported nickel catalysts at 600°C in nitrogen?