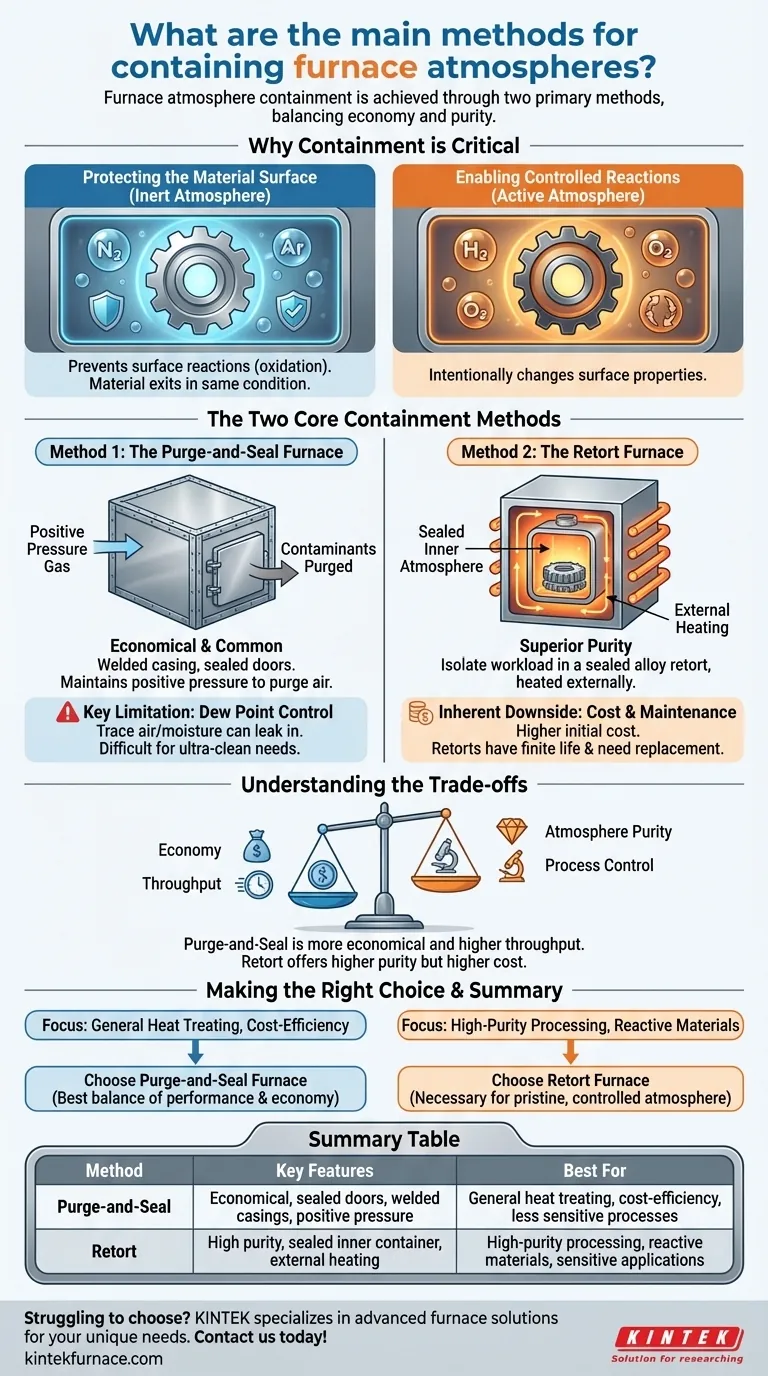

At its core, furnace atmosphere containment is achieved through two primary methods: the purge-and-seal design and the retort design. The purge-and-seal method relies on sealed doors and welded casings to contain the atmosphere and is more economical, while the retort method uses a sealed inner container (the retort) that is heated externally, offering superior atmospheric purity at a higher cost.

The choice between furnace containment methods is not about which is "better," but which provides the necessary level of atmospheric control for your specific process. It is a direct trade-off between the economic efficiency of a purge-and-seal system and the high-purity results of a retort furnace.

Why Atmosphere Containment is Critical

The entire purpose of a controlled furnace atmosphere is to govern what happens to a material's surface at high temperatures. The containment method you choose directly impacts your ability to achieve the desired outcome.

Protecting the Material Surface

Many heat-treating processes require a chemically inert atmosphere, typically using gases like nitrogen or argon. The goal is simply to prevent surface reactions like oxidation, ensuring the material exits the furnace in the same surface condition it entered.

Enabling Controlled Reactions

Conversely, some processes use a chemically active atmosphere to intentionally change the material's surface. These can be reducing gases like hydrogen or oxidizing gases like oxygen, which are used for processes such as carburizing or decarburizing.

The Two Core Containment Methods

Understanding the fundamental design of each method reveals its inherent strengths and weaknesses.

Method 1: The Purge-and-Seal Furnace

This design is the most common and cost-effective approach for many heat-treating applications. The furnace chamber is constructed with welded seams and features seals around doors and other openings.

A positive pressure of the desired atmosphere gas is maintained inside, which purges any contaminants and prevents outside air from leaking in.

The Key Limitation: Dew Point Control

The primary challenge with purge-and-seal furnaces is achieving a very low dew point, which is a measure of moisture content. Because the chamber is not perfectly sealed, trace amounts of air and moisture can leak in, making it difficult to maintain the ultra-clean atmosphere required for highly sensitive materials.

Method 2: The Retort Furnace

A retort furnace isolates the workload and its atmosphere inside a separate, sealed container—the retort—which is typically made of a high-temperature alloy. This container is then placed inside the furnace and heated externally.

Because the workload is in a fully sealed vessel, this method provides exceptional atmospheric purity and precise control over gas composition.

The Inherent Downside: Cost and Maintenance

The benefits of a retort come at a price. Retort furnaces are more expensive to build, and the alloy retorts themselves have a finite lifespan and require periodic replacement. This leads to higher initial investment and ongoing maintenance costs.

Understanding the Trade-offs: Economy vs. Purity

The decision to use a purge-and-seal or a retort furnace is a classic engineering trade-off.

Cost Considerations

Purge-and-seal furnaces are significantly more economical to purchase and operate for general-purpose applications. Retort furnaces carry a higher capital cost and recurring operational expenses due to retort replacement and more complex handling.

Atmosphere Purity and Process Sensitivity

If your process is tolerant of slight variations in atmosphere or does not require an extremely low dew point, a purge-and-seal design is often sufficient. For materials that are highly reactive or for processes requiring absolute gas purity, a retort is non-negotiable.

Operational Footprint and Throughput

Purge-and-seal furnaces are often simpler and can be designed for continuous operation, offering higher throughput. Retort furnaces are typically used in batch processes, which can be slower due to the need to load, seal, and handle the individual retorts.

Making the Right Choice for Your Process

Your process requirements, not a general preference, should dictate your choice of furnace.

- If your primary focus is general heat treating or cost-efficiency: A purge-and-seal furnace offers the best balance of performance and economy for applications that are not highly sensitive to atmospheric impurities.

- If your primary focus is high-purity processing or reactive materials: A retort furnace is the necessary choice for achieving the pristine, tightly controlled atmosphere required for sensitive components and advanced processes.

Ultimately, selecting the right containment method is about matching the tool precisely to the task at hand.

Summary Table:

| Method | Key Features | Best For |

|---|---|---|

| Purge-and-Seal | Economical, sealed doors, welded casings, positive pressure | General heat treating, cost-efficiency, less sensitive processes |

| Retort | High purity, sealed inner container, external heating | High-purity processing, reactive materials, sensitive applications |

Struggling to choose the right furnace for your lab's atmosphere control needs? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental requirements—ensuring optimal performance and efficiency. Contact us today to discuss how we can enhance your heat treatment processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance