At its core, a brazing furnace is specialized industrial equipment that joins metal components by heating them in a highly controlled environment. It uses a filler metal with a lower melting point than the base parts, which melts and flows into the joint through capillary action. Upon cooling, this filler solidifies to create a strong, clean, metallurgical bond without ever melting the components themselves.

The true value of a brazing furnace is not simply the heat it provides, but the precise environmental control it offers. By managing the atmosphere, particularly by creating a vacuum, it eliminates contaminants like oxygen to produce exceptionally strong and clean bonds that are unattainable with open-air methods.

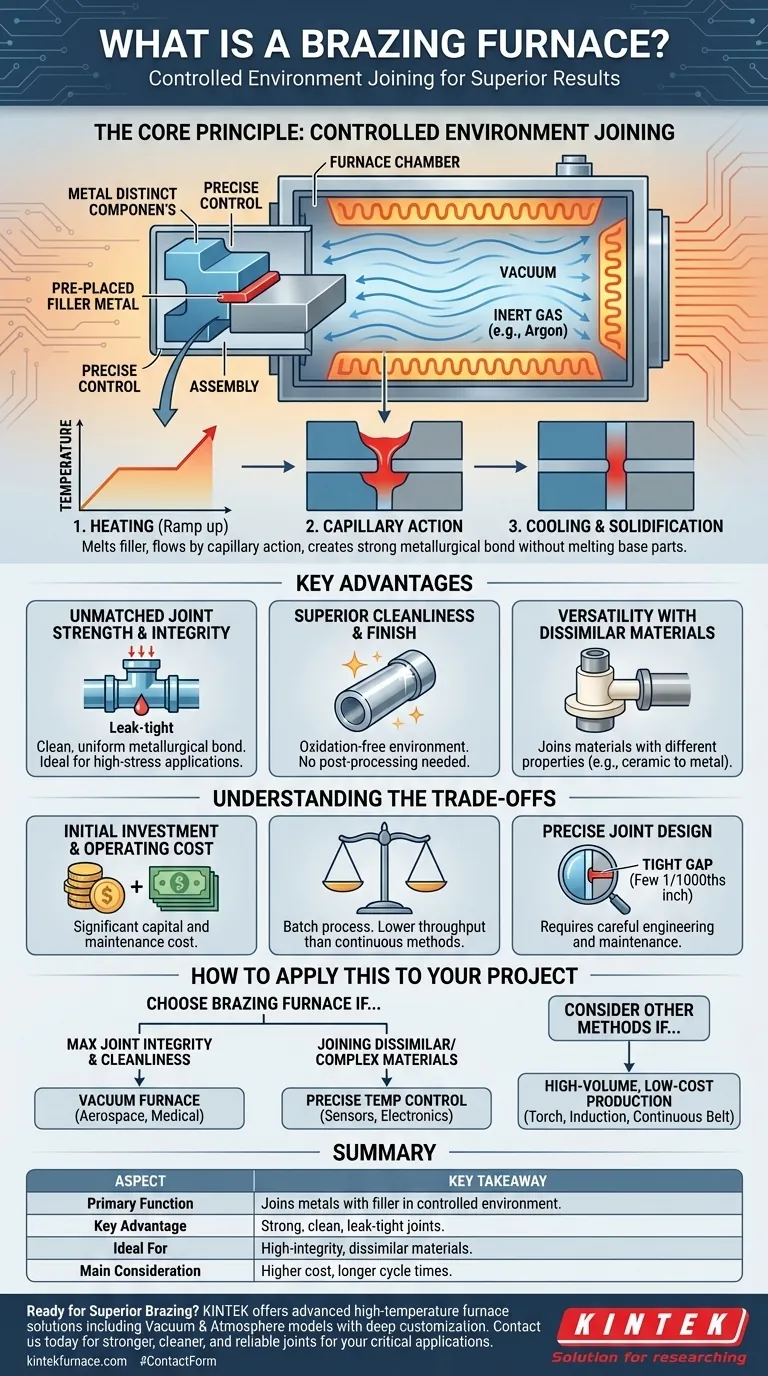

The Core Principle: Controlled Environment Joining

Furnace brazing is fundamentally a process of precision. It moves beyond the brute-force heating of a torch to a meticulously managed thermal cycle within a contained atmosphere.

How the Process Unfolds

First, the metal components are assembled with the filler metal pre-placed at the joint. The entire assembly is then loaded into the furnace. The furnace chamber is sealed, and the atmosphere is modified—often by pulling a vacuum or introducing an inert gas. The temperature is then ramped up to a precise point above the filler metal's melting point but safely below that of the base metals.

The molten filler is drawn into the tight gap between the parts by capillary action. After a set time at temperature, the assembly is cooled in a controlled manner. The filler metal solidifies, forming a permanent, high-integrity bond between the parts.

The Critical Role of the Atmosphere

The controlled environment is what separates furnace brazing from other methods. In open air, heating metals causes oxidation, a form of corrosion that creates a weak, brittle oxide layer on the surface. This layer prevents the filler metal from properly wetting the base materials, resulting in a poor or failed joint.

A vacuum brazing furnace is the gold standard for control. By removing almost all of the air, it creates a clean, oxidation-free environment, ensuring the final joint is as strong and pure as possible.

Key Advantages in Industrial Applications

The control offered by a brazing furnace translates directly into tangible benefits for manufacturing complex or high-performance parts.

Unmatched Joint Strength and Integrity

Because the process creates a clean, uniform metallurgical bond across the entire joint surface, the resulting connection is incredibly strong and often leak-tight. This makes furnace brazing ideal for components that must withstand high pressure or stress.

Superior Cleanliness and Finish

With no oxidation, the brazed assembly emerges from the furnace clean and often requires no post-processing or cleaning. This saves time and resources while producing a visually superior product.

Versatility with Dissimilar Materials

The furnace's precise temperature control allows for the joining of materials with very different properties, such as ceramics and metals. This is extremely difficult to achieve with less controlled heating methods, making furnace brazing essential for advanced components like sensors and high-performance electronics.

Understanding the Trade-offs

While powerful, furnace brazing is not the solution for every joining challenge. Objectivity requires acknowledging its limitations.

Initial Investment and Operating Cost

Brazing furnaces, particularly advanced vacuum models, represent a significant capital investment. They are complex machines that require specialized infrastructure and maintenance, leading to higher operating costs compared to simpler methods like torch brazing.

Cycle Time and Throughput

Furnace brazing is typically a batch process. The time required to load the furnace, pull a vacuum, run the thermal cycle, and cool down can be lengthy. This results in a lower throughput than continuous or manual brazing methods, making it less suitable for certain high-volume production lines.

Requirement for Precise Joint Design

The process relies on capillary action to distribute the filler metal. This means the gap between the components being joined must be carefully engineered and maintained—typically just a few thousandths of an inch. This adds a layer of complexity to the part design and manufacturing process.

How to Apply This to Your Project

Choosing the right joining method depends entirely on your project's technical requirements and business goals.

- If your primary focus is maximum joint integrity and cleanliness: A vacuum brazing furnace is the superior choice for creating oxidation-free, high-strength bonds, especially for critical aerospace, medical, or electronic applications.

- If your primary focus is joining dissimilar or complex materials: The precise temperature control of a furnace is essential for successfully bonding materials like ceramics to metals or parts with intricate geometries.

- If your primary focus is high-volume, low-cost production: Simpler methods like torch, induction, or continuous belt furnace brazing might be more cost-effective, as they offer faster cycle times for less critical applications.

Ultimately, choosing to use a brazing furnace is a strategic decision to prioritize quality, reliability, and material versatility in your design.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Joins metal components using a filler metal in a controlled environment. |

| Key Advantage | Creates exceptionally strong, clean, and leak-tight joints without melting the base parts. |

| Ideal For | High-integrity applications in aerospace, medical, and electronics; joining dissimilar materials. |

| Main Consideration | Higher initial investment and longer cycle times compared to simpler methods. |

Ready to Achieve Superior Brazing Results?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique brazing requirements.

Contact us today to discuss how our expertise can help you create stronger, cleaner, and more reliable joints for your critical applications.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems