The primary function of a composite tungsten wire mesh wick is to optimize the circulation of liquid sodium by decoupling capillary pressure from flow resistance. By layering meshes of different specifications, specifically 50 mesh and 400 mesh, the structure creates a powerful driving force to move the fluid while simultaneously ensuring the pathway remains open enough for efficient backflow.

Core Takeaway A single mesh size forces a compromise between pumping power and flow restriction. The composite wick eliminates this bottleneck, providing the high capillary pressure needed to prevent dry-out without choking the flow of liquid sodium, particularly in long, thin heat pipes.

The Mechanics of Composite Wicks

The Dual-Layer Strategy

The effectiveness of this wick relies on combining tungsten wire meshes of vastly different specifications.

The design typically integrates a coarse layer (such as 50 mesh) with a fine layer (such as 400 mesh). This hybrid approach allows the heat pipe to leverage the physical advantages of both geometries simultaneously.

Generating Capillary Driving Force

The finer mesh layer (400 mesh) is responsible for the capillary driving force.

Because the pores are smaller, they generate significantly higher capillary pressure. This pressure acts as the "pump" that pulls the liquid sodium from the condenser back to the evaporator, ensuring continuous movement even against gravity.

Maintaining Fluid Permeability

The coarser mesh layer (50 mesh) addresses the issue of flow resistance.

If the entire wick were made of fine mesh, the friction would be too high for the fluid to move quickly. The coarser layer creates a more open structure, providing high permeability that allows the liquid sodium to flow back with minimal resistance.

Operational Benefits

Preventing Evaporator Dry-Out

The most critical function of this composite structure is ensuring the evaporation section never runs dry.

By balancing the driving force with low resistance, the wick supplies liquid sodium to the hot zone faster than it evaporates. This stability is essential for maintaining the heat pipe's thermal conductivity and preventing failure.

Supporting High-Aspect-Ratio Structures

This wick design is particularly beneficial for high-aspect-ratio structures (long and thin pipes).

In these geometries, the fluid must travel longer distances, which typically increases flow resistance. The composite tungsten mesh overcomes this distance challenge, maintaining effective circulation where a standard homogenous wick might fail.

Understanding the Trade-offs

Complexity vs. Performance

While the reference highlights cost-effective manufacturing, composite wicks are inherently more complex than single-layer designs.

The engineering challenge lies in ensuring perfect contact between the layers. If the interface between the 50 mesh and 400 mesh is not uniform, the capillary continuity can break, disrupting the fluid loop.

The Specificity of Sodium

This specific configuration is optimized for liquid sodium, which is used in high-temperature applications.

The mesh sizes (50/400) are selected specifically for the surface tension and viscosity properties of sodium. Using this exact composite structure for a different working fluid (like water or ammonia) would likely require re-optimizing the mesh specifications to achieve the same balance.

Making the Right Choice for Your Goal

If you are evaluating heat pipe designs, consider how the wick structure aligns with your operational constraints:

- If your primary focus is Reliability: Prioritize the composite design to ensure the evaporation section does not dry out under high thermal loads.

- If your primary focus is Geometry: Use this wick type for high-aspect-ratio applications where fluid must travel long distances without losing pressure.

The composite wick effectively solves the hydrodynamic conflict between pumping and flow, enabling high performance in demanding thermal environments.

Summary Table:

| Feature | Layer Specification | Primary Function |

|---|---|---|

| Capillary Layer | 400 Mesh (Fine) | Generates high capillary pressure to pump liquid sodium. |

| Permeability Layer | 50 Mesh (Coarse) | Reduces flow resistance to ensure rapid fluid backflow. |

| Total System | Composite Structure | Decouples pressure from friction for high-aspect-ratio pipes. |

Elevate Your High-Temperature Research with KINTEK

Don’t let thermal bottlenecks compromise your precision. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all backed by our expert R&D and manufacturing. Whether you need specialized heat pipe components or fully customizable lab furnaces, our engineering team is ready to deliver systems tailored to your unique requirements.

Ready to optimize your thermal performance? Contact KINTEK today and let us design the perfect solution for your lab.

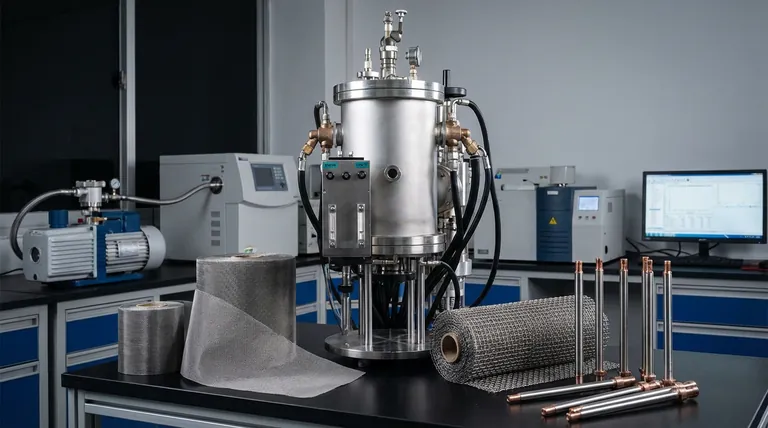

Visual Guide

References

- Shuaijie Sha, Junjie Wang. Experimental and numerical simulation study of sodium heat pipe with large aspect ratio. DOI: 10.2298/tsci231030059s

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a W/Re-20 thermocouple play in SHS of tungsten carbide? Precision Monitoring for Extreme 2300°C Reactions

- What are the applications of SC Type Silicon Carbide Heating Elements in heat treatment? Achieve Uniform High-Temperature Control

- What are the key features of Silicon Carbide Heating Elements? Unlock High-Temp Precision and Durability

- How does Joule heating work in heating elements? Master Efficient Heat Generation for Your Lab

- What scientific instruments use heating elements? Essential Tools for Precise Temperature Control

- What are the advantages of using a C-type thermocouple in high-temperature experiments? Unlock Precision Above 1000 °C

- Which heating element is more brittle, SiC or MoSi2? Choose the Right Element for Your High-Temp Needs

- How does an electric heating system ensure stable ignition during coal gasification? Achieving Reliable Process Control