From a purely mechanical standpoint, Silicon Carbide (SiC) heating elements are more brittle than Molybdenum Disilicide (MoSi2) elements. This inherent brittleness makes SiC more susceptible to fracture and failure when subjected to the stress of repeated thermal cycling—the process of heating up and cooling down.

While SiC is indeed more brittle, the choice between these two materials is not a simple matter of durability. The correct decision depends on a critical trade-off between your required operating temperature, desired heating speed, and your team's capacity for furnace maintenance.

The Core Difference: Mechanical vs. Thermal Performance

The choice between SiC and MoSi2 is fundamentally a choice between different operational strengths. Each material excels under specific conditions, and understanding these differences is key to ensuring furnace reliability and efficiency.

Brittleness and Thermal Shock

SiC's higher brittleness means it has a lower tolerance for the mechanical stress induced by rapid temperature changes. This can lead to cracking and a shorter operational lifespan, especially in processes that require frequent cycles.

MoSi2 elements are mechanically tougher at operating temperatures and better withstand thermal shock, giving them an advantage in terms of raw durability against temperature swings.

Maximum Operating Temperature

This is often the most significant deciding factor. MoSi2 elements can operate at significantly higher temperatures. They can reach surface temperatures of 1800-1900°C, allowing for stable furnace operation in the 1600-1700°C range.

SiC elements have a lower maximum surface temperature of around 1600°C. This translates to a reliable maximum furnace temperature of approximately 1530-1540°C.

Lifespan and Aging

SiC elements tend to have a shorter lifespan, partly due to their brittleness. Critically, their electrical resistance increases as they age. When one element fails, you often must replace the entire set to maintain balanced electrical loads.

MoSi2 elements generally last longer, especially when operated consistently above 1500°C. Their resistance is more stable over time, simplifying replacement.

Understanding the Trade-offs

Neither material is universally superior. Your specific process requirements will expose the advantages and disadvantages of each.

The Speed of SiC: Thermal Conductivity

SiC has a higher thermal conductivity. This allows it to transfer heat more efficiently, resulting in faster furnace heat-up times. This is a major advantage for processes requiring rapid thermal response.

MoSi2, with its lower thermal conductivity, is better suited for slower, more controlled heating processes where maximum temperature is the priority.

The Sensitivity of MoSi2: Contamination Risk

This is the primary weakness of MoSi2. These elements are highly susceptible to contamination. Improper furnace maintenance or the presence of certain process byproducts can lead to rapid degradation and premature failure.

SiC elements are generally more forgiving of atmospheric variations and less sensitive to contamination, making them more robust in less-controlled process environments.

The Practicality of Replacement

SiC elements are typically wired in parallel. Combined with their tendency to age and change resistance, this often necessitates replacing them in matched sets, which can increase maintenance costs and downtime.

MoSi2 elements are wired in series. While a single failure can take down a heating circuit, their stable resistance makes individual replacement more feasible, though the elements themselves can carry a higher initial cost.

Making the Right Choice for Your Application

Your operational goal is the ultimate guide. Select the element that aligns with your process priorities, not just one based on a single material property.

- If your primary focus is maximum temperature and longevity: Choose MoSi2 for processes running consistently above 1540°C, but commit to a rigorous maintenance schedule to prevent contamination.

- If your primary focus is rapid heating cycles below 1500°C: Choose SiC for its excellent thermal response and greater forgiveness in varied atmospheres, but plan for shorter lifespans and set-based replacements.

- If your primary focus is balancing performance and maintenance: Carefully evaluate your process. If temperatures are borderline (around 1500-1540°C), weigh the faster heating of SiC against the longer potential life of a well-maintained MoSi2 system.

Ultimately, an informed choice is based on a complete picture of your process needs, not just a single material characteristic.

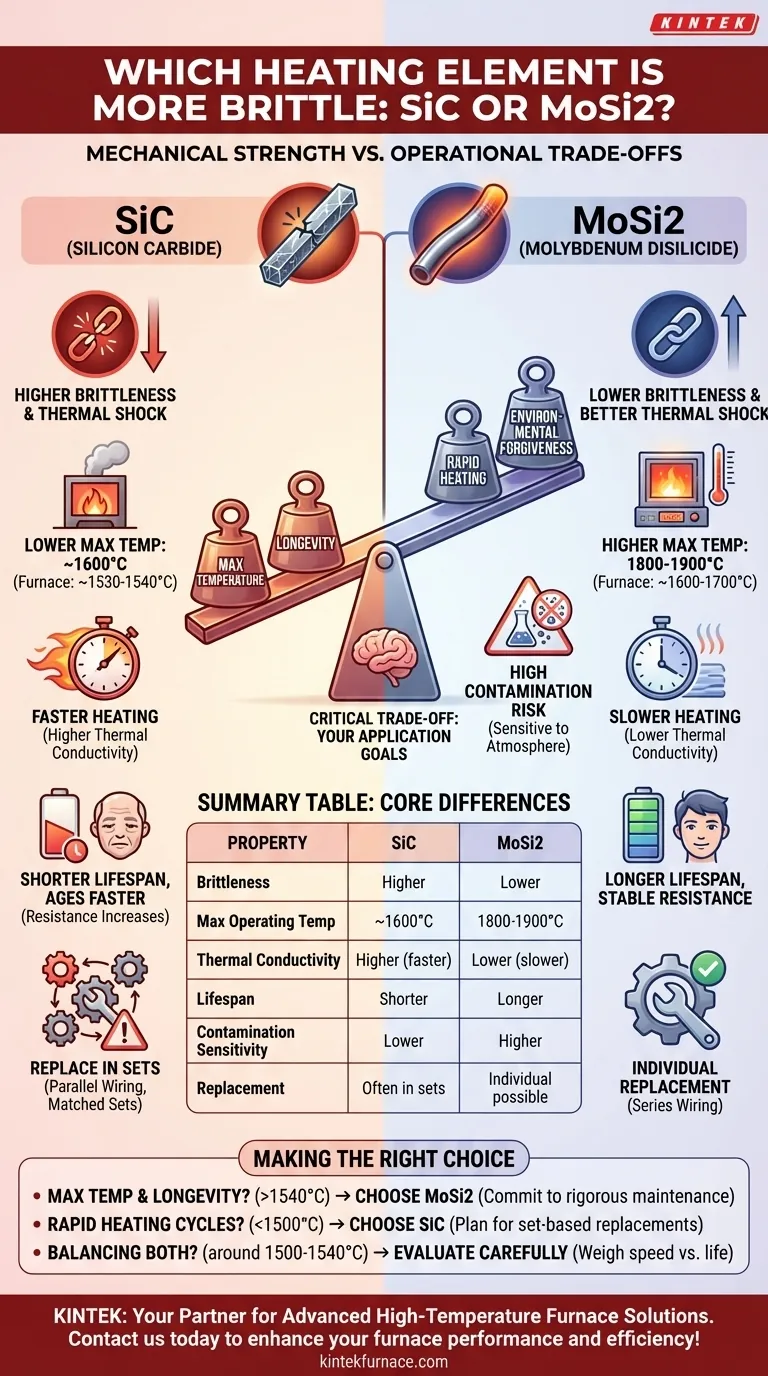

Summary Table:

| Property | SiC | MoSi2 |

|---|---|---|

| Brittleness | Higher | Lower |

| Max Operating Temperature | ~1600°C | 1800-1900°C |

| Thermal Conductivity | Higher (faster heating) | Lower (slower heating) |

| Lifespan | Shorter | Longer |

| Contamination Sensitivity | Lower | Higher |

| Replacement | Often in sets | Individual possible |

Struggling to choose the right heating element for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your furnace performance and efficiency!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer