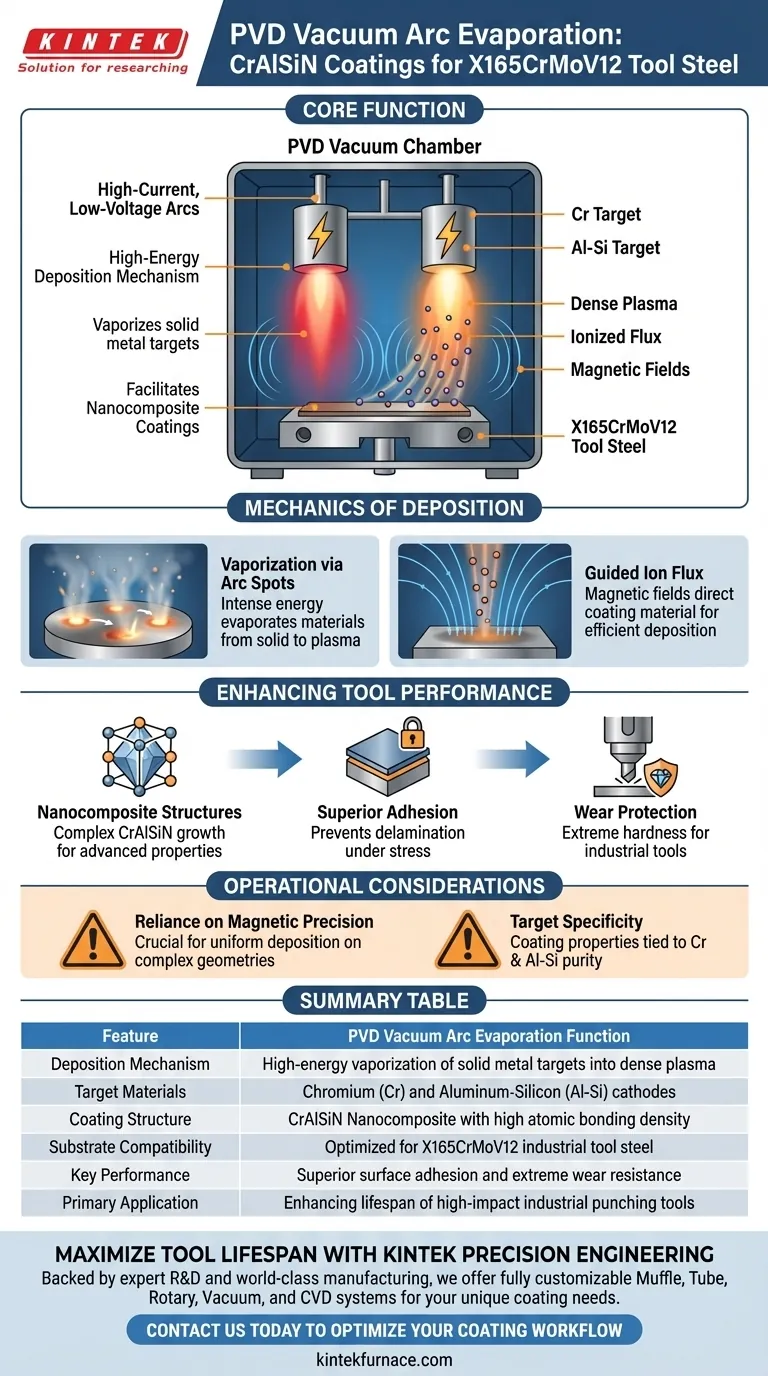

PVD Vacuum Arc Evaporation functions as a high-energy deposition mechanism that vaporizes solid metal targets into a dense plasma for coating applications. By utilizing high-current, low-voltage arcs on Chromium (Cr) and Aluminum-Silicon (Al-Si) cathodes, the technology generates an ionized flux that is magnetically guided to bond directly to the X165CrMoV12 tool steel substrate.

Core Insight: The primary function of this technology is to facilitate the formation of nanocomposite coatings through controlled atomic evaporation. This process creates a surface layer with superior adhesion and extreme hardness, specifically engineered to extend the lifespan of industrial punching tools.

The Mechanics of Deposition

Vaporization via Arc Spots

The core of this technology lies in the generation of moving spots on the surface of cathode targets. High-current, low-voltage vacuum arcs are applied to specific materials, such as Chromium (Cr) and Aluminum-Silicon (Al-Si). This intense energy causes the target materials to evaporate rapidly, transitioning from a solid state into a plasma.

Guided Ion Flux

Once the material is evaporated, it creates a flux of ions. This ion flux is not random; it is actively guided by magnetic fields within the vacuum chamber. These fields direct the coating material precisely onto the surface of the X165CrMoV12 tool steel, ensuring efficient deposition.

Enhancing Tool Performance

Creation of Nanocomposite Structures

The simultaneous evaporation of Cr and Al-Si targets facilitates the growth of CrAlSiN nanocomposite coatings. This complex structural arrangement is key to the coating's advanced physical properties. It moves beyond simple layering to create a robust, integrated material structure.

Achieving Superior Adhesion

A critical function of the vacuum arc process is ensuring the coating stays attached under stress. The high-energy nature of the ion flux results in high adhesion between the coating and the tool steel substrate. This prevents delamination (peeling) during high-impact operations.

Wear Protection for Industrial Tools

The ultimate functional goal is to harden the tool surface. The resulting coating provides extreme hardness and wear protection. This is particularly vital for industrial punching tools, which are subjected to repetitive mechanical stress and abrasion.

Operational Considerations and Trade-offs

Reliance on Magnetic Precision

The quality of the deposition is heavily dependent on the control of the magnetic fields. Without precise magnetic guidance, the ion flux may not deposit uniformly across the complex geometries of a tool. This adds a layer of complexity to the equipment setup and calibration compared to non-directed deposition methods.

Target Specificity

The process described relies specifically on the availability and purity of Cr and Al-Si targets. The properties of the final nanocomposite are directly tied to the composition of these cathodes. Any inconsistency in the target material will directly impact the hardness and adhesion of the final coating.

Making the Right Choice for Your Goal

The PVD Vacuum Arc Evaporation process is a specialized solution for high-stress industrial applications. Here is how to verify if it aligns with your objectives:

- If your primary focus is Durability: This technology is ideal because it generates extreme hardness required to protect punching tools from premature wear.

- If your primary focus is Reliability: The process is recommended due to its ability to create high adhesion, minimizing the risk of coating failure during operation.

Summary: PVD Vacuum Arc Evaporation is the definitive method for transforming standard tool steel into a high-performance, wear-resistant asset through the precise application of nanocomposite coatings.

Summary Table:

| Feature | PVD Vacuum Arc Evaporation Function |

|---|---|

| Deposition Mechanism | High-energy vaporization of solid metal targets into dense plasma |

| Target Materials | Chromium (Cr) and Aluminum-Silicon (Al-Si) cathodes |

| Coating Structure | CrAlSiN Nanocomposite with high atomic bonding density |

| Substrate Compatibility | Optimized for X165CrMoV12 industrial tool steel |

| Key Performance | Superior surface adhesion and extreme wear resistance |

| Primary Application | Enhancing lifespan of high-impact industrial punching tools |

Maximize Tool Lifespan with KINTEK Precision Engineering

Is your production line suffering from premature tool wear? KINTEK provides the advanced heating and deposition solutions needed to master the PVD process. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique coating and heat treatment specifications.

Whether you are depositing nanocomposites for punching tools or researching the next generation of thin films, KINTEK’s lab high-temp furnaces deliver the thermal precision required for superior adhesion and hardness. Contact us today to optimize your coating workflow!

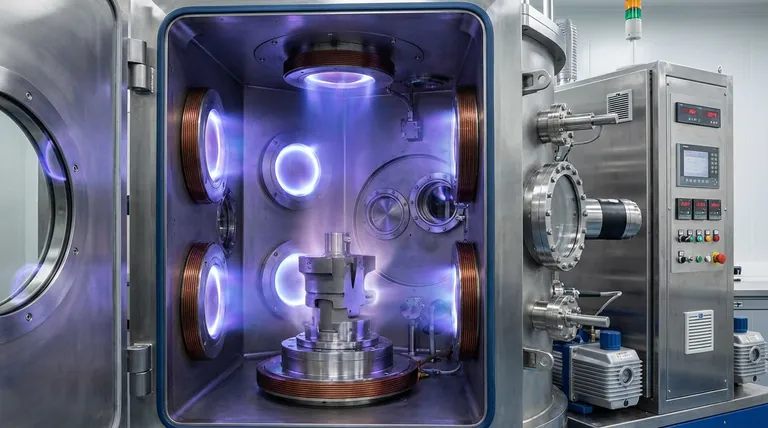

Visual Guide

References

- Sergey N. Grigoriev, Anna A. Okunkova. Increasing the Wear Resistance of Stamping Tools for Coordinate Punching of Sheet Steel Using CrAlSiN and DLC:Si Coatings. DOI: 10.3390/technologies13010030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How does a phosphorus diffusion furnace contribute to defect engineering? Transform UMG-Si into High-Efficiency Solar

- What is the difference between chemical vapor transport and chemical vapor deposition? A Guide to Coating vs. Crystal Growth

- What role does a Chemical Vapor Deposition (CVD) tube furnace system play in the preparation of monolayer graphene?

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- In which fields are CVD furnaces widely applied? Essential for Semiconductors, Aerospace, and More

- Why is the all-or-nothing nature of CVD a drawback? Limits Control and Increases Costs

- What are the quartz tube sizes compatible with these CVD systems? Optimize Your Process with 1-Inch or 2-Inch Tubes

- Why is the CVD furnace considered a cornerstone of advanced material synthesis? Unlock Atomic-Level Material Control