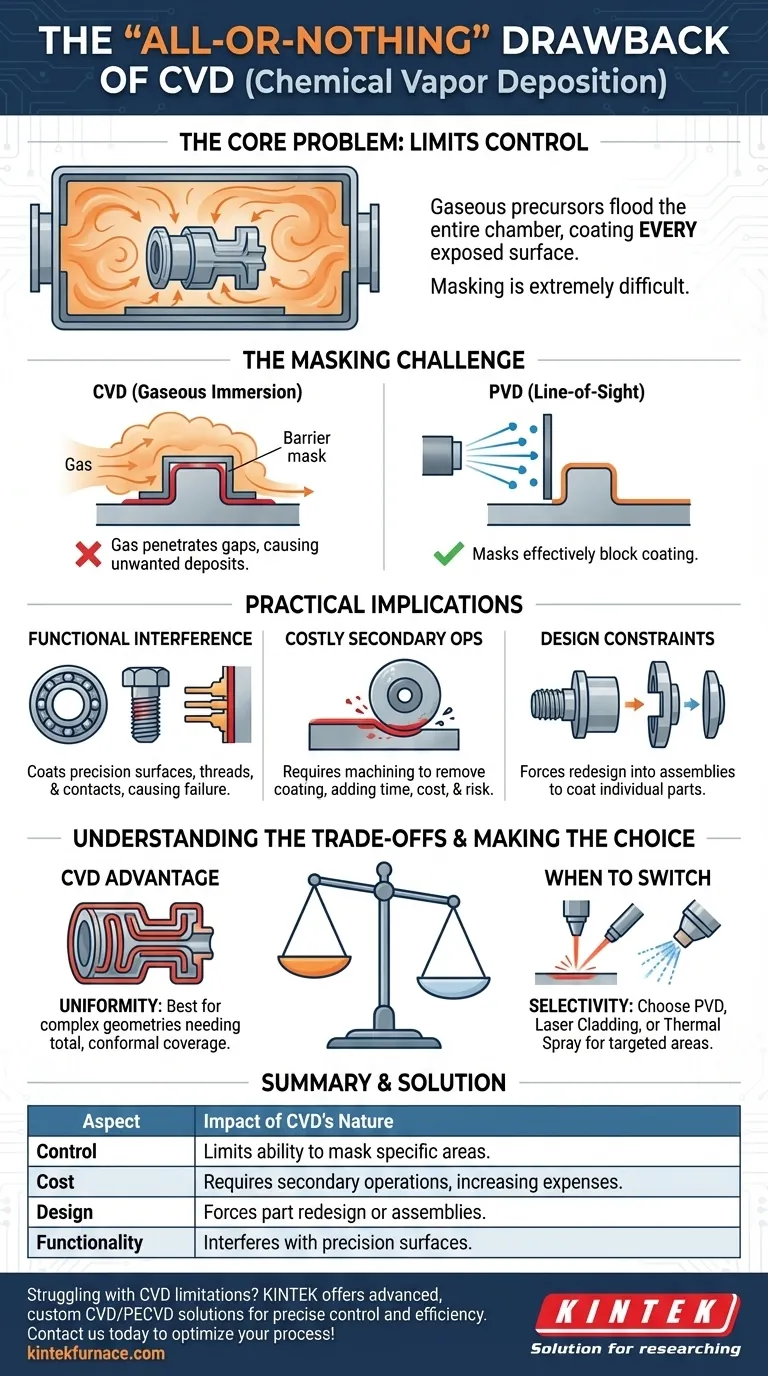

At its core, the "all-or-nothing" nature of Chemical Vapor Deposition (CVD) is a drawback because it fundamentally limits control. The process is designed to flood a reaction chamber with gaseous precursors that deposit a uniform coating on every exposed surface. This makes it extremely difficult to mask or protect specific areas, restricting its use in applications where only a portion of a component requires the coating's properties.

The primary challenge of CVD's "all-or-nothing" behavior stems from the extreme difficulty of effectively masking parts within its gaseous environment. This makes it impractical for components that require both coated and uncoated functional surfaces to operate correctly.

The Challenge: Masking in a Gaseous Environment

To understand why selective coating is so difficult, you must first understand the CVD process itself. It isn't like painting a liquid or powder that can be blocked by simple tape or fixtures.

How CVD Achieves Total Coverage

The CVD process involves heating a substrate (the part to be coated) inside a vacuum chamber. Volatile precursor gases are then introduced, which react and decompose on the hot surfaces to form a solid, thin film.

Because the component is immersed in this reactive gas, the coating deposits on every surface the gas can reach, including complex internal geometries, undercuts, and blind holes. This ability to create a perfectly conformal and uniform layer is one of CVD's greatest strengths.

Why Typical Masking Fails

This gaseous immersion is also the source of the drawback. The precursor gases can easily penetrate the smallest gaps, seeping under the edges of traditional masks.

Unlike a line-of-sight process like spraying, you cannot simply block off an area. The gas will flow around any barrier, rendering most simple masking techniques ineffective and resulting in an unwanted coating deposit.

Practical Implications of Uncontrolled Coating

When a design requires both coated and uncoated surfaces on a single part, the all-or-nothing nature of CVD introduces significant engineering and cost challenges.

Interference with Functionality

Many components have areas that must remain uncoated to function. A coating, no matter how thin, can be detrimental on:

- Precision-fit surfaces like bearing journals.

- Threaded holes where tolerances are critical.

- Electrical contact points that require conductivity.

An unwanted coating in these areas can cause part failure, require costly rework, or render the component useless.

The Need for Secondary Operations

The most common workaround is to coat the entire part and then use a secondary process, like grinding or precision machining, to remove the coating from the areas where it's not wanted.

This approach adds significant time and cost to production and introduces the risk of damaging the part or the desired coating during the removal process.

Constraints on Part Design

This limitation forces engineers to design around the process. A single, complex part that needs partial coating might have to be redesigned as a multi-part assembly.

Each piece can be coated individually and then assembled, adding complexity to the manufacturing, inventory, and assembly stages of production.

Understanding the Trade-offs

The "all-or-nothing" characteristic is only a drawback when partial coating is the goal. In many cases, this same characteristic is a distinct advantage.

Uniformity as a Key Strength

When you need to coat an entire component, especially one with complex shapes or internal channels, CVD is often the superior choice. Its ability to deliver a completely uniform layer is unmatched by many other techniques.

Comparison to Line-of-Sight Processes

Processes like Physical Vapor Deposition (PVD) are "line-of-sight," meaning the coating material travels in a straight line from the source to the substrate.

This makes masking and partial coating much easier in PVD. However, it also makes it very difficult to coat complex geometries, internal bores, or the "shadowed" side of a part without complex rotation and fixtures.

Other CVD Limitations to Consider

Beyond masking, other factors can make CVD unsuitable. The process often requires high temperatures that can damage or warp sensitive substrates. The size of the component is also limited by the dimensions of the reaction chamber.

Making the Right Choice for Your Application

The decision to use CVD must be based on the functional requirements of your component and the geometry you need to coat.

- If your primary focus is coating an entire component with a highly uniform, conformal layer: CVD is an excellent choice, as its "all-or-nothing" nature becomes a significant advantage.

- If your primary focus is coating only a specific, targeted area of a part: You should explore alternatives like PVD, laser cladding, or thermal spray, as the difficulty and cost of masking make CVD impractical.

- If your component requires both coated and uncoated surfaces and cannot be easily disassembled: Carefully weigh the cost and risk of secondary machining to remove unwanted CVD coating against using a different, more selective process.

By understanding that CVD's greatest strength is also the source of its primary limitation, you can select the most effective and economical coating strategy for your project.

Summary Table:

| Aspect | Impact of CVD's All-or-Nothing Nature |

|---|---|

| Control | Limits ability to mask specific areas, leading to uniform coating on all exposed surfaces |

| Cost | Requires secondary operations like machining to remove unwanted coatings, increasing expenses |

| Design | Forces part redesign or multi-part assemblies for partial coating needs |

| Functionality | Can interfere with precision-fit surfaces, threads, or electrical contacts |

| Alternatives | PVD, laser cladding, or thermal spray offer better selectivity for targeted coating |

Struggling with CVD's limitations in your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions, including CVD/PECVD Systems, to overcome these challenges. Leveraging our exceptional R&D and in-house manufacturing, we provide deep customization to meet your unique experimental needs, ensuring precise control and efficiency. Contact us today via our contact form to discuss how our Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces can optimize your coating processes and reduce costs!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Which industries and research fields benefit from CVD tube furnace sintering systems for 2D materials? Unlock Next-Gen Tech Innovations

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision