At its core, the function of adjustable speed control in a rotary kiln is to give operators precise command over the rotational velocity of the kiln shell. This capability, typically enabled by frequency conversion technology, allows for the fine-tuning of processing conditions to match the specific requirements of different materials and operational goals.

Adjustable speed control is not simply about going faster or slower; it is the primary mechanism for controlling material residence time and heat transfer, which are the two most critical variables determining the efficiency and quality of the final product.

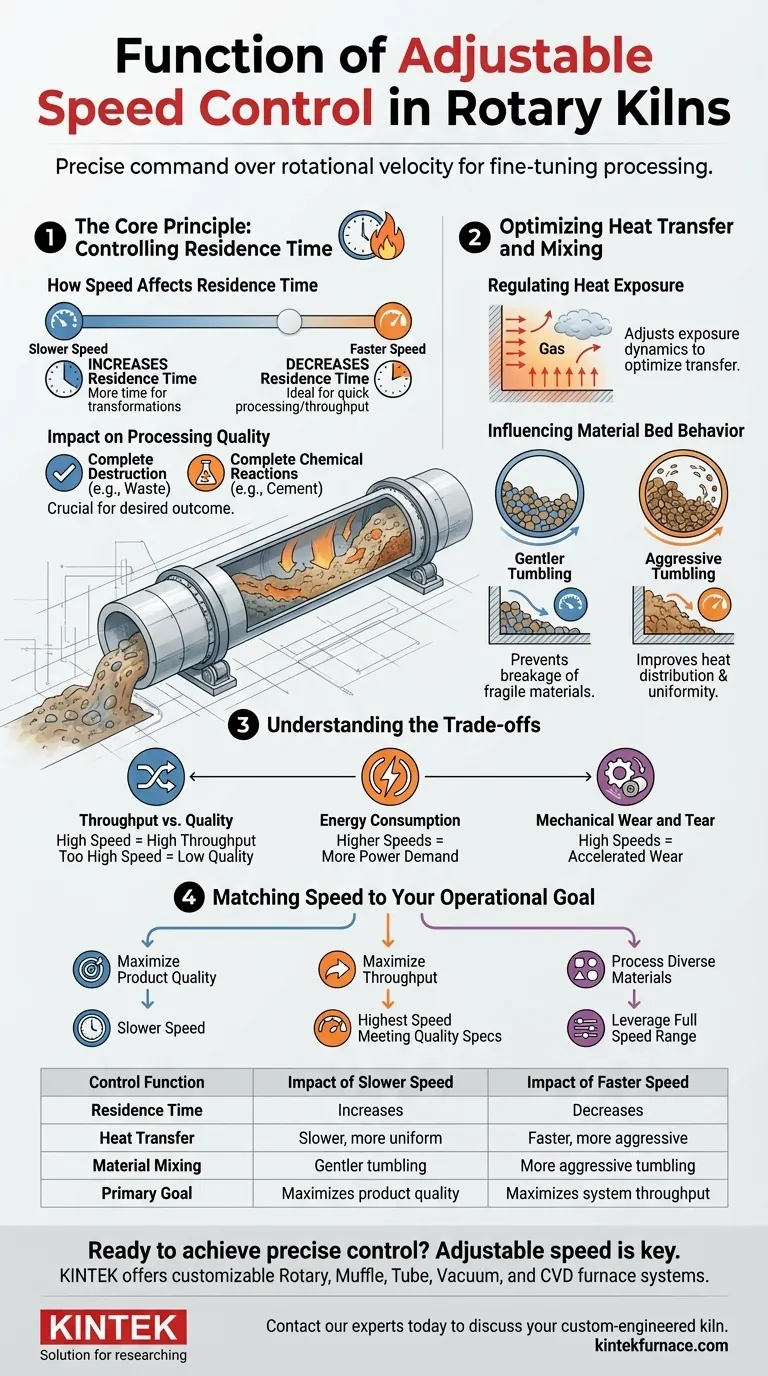

The Core Principle: Controlling Residence Time

The most direct impact of adjusting a kiln's rotational speed is on the amount of time material spends inside it. This duration is known as residence time.

How Speed Affects Residence Time

A slower rotation speed increases the residence time. This gives the material more time to absorb heat and undergo the necessary chemical or physical transformations.

A faster rotation speed decreases the residence time. This is ideal for materials that process quickly or for increasing the overall throughput of the system.

The Impact on Processing Quality

Controlling residence time is fundamental to achieving the desired outcome. For processes like hazardous waste incineration, a longer residence time ensures complete destruction of contaminants. In cement or lime production, it guarantees the chemical reactions have gone to completion.

Optimizing Heat Transfer and Mixing

Beyond residence time, speed control is crucial for managing how heat is transferred to the material and how the material bed behaves inside the kiln.

Regulating Heat Exposure

The material inside a kiln is heated by both direct contact with the hot refractory wall and the hot gases flowing through the kiln. Adjusting the speed changes the dynamics of this exposure, allowing operators to optimize heat transfer for specific material properties.

Influencing Material Bed Behavior

The tumbling action caused by the kiln's rotation is essential for mixing the material and exposing new surfaces to the heat. A faster speed creates a more aggressive tumbling action, which can improve heat distribution and process uniformity for certain materials. Conversely, a slower, gentler action may be required for fragile materials to prevent them from breaking down.

Understanding the Trade-offs

While flexible, adjustable speed control requires balancing competing operational priorities. Understanding these trade-offs is key to effective kiln management.

Throughput vs. Quality

There is a constant tension between processing speed and product quality. Running the kiln faster increases throughput (tons per hour), but if the speed is too high, the reduced residence time may lead to incomplete processing and a low-quality or out-of-spec product.

Energy Consumption

Higher rotational speeds typically demand more power from the main drive motor. Operators must balance the need for speed with the resulting impact on energy costs.

Mechanical Wear and Tear

Consistently operating at very high speeds can accelerate wear on mechanical components such as the drive train, support rollers, and riding rings. This can lead to increased maintenance requirements and potential downtime over the long term.

Matching Speed to Your Operational Goal

The ideal speed setting is entirely dependent on your primary objective.

- If your primary focus is maximizing product quality: Prioritize a slower, more deliberate speed that guarantees sufficient residence time for complete chemical and physical transformation.

- If your primary focus is maximizing throughput: Carefully increase the speed to the highest point that still meets the minimum acceptable quality specifications for your product.

- If your primary focus is processing diverse materials: Leverage the full range of speed control to develop unique operational profiles tailored to the specific thermal and chemical properties of each feedstock.

Ultimately, adjustable speed control transforms the rotary kiln from a static piece of hardware into a precise and highly adaptable processing instrument.

Summary Table:

| Control Function | Impact of Slower Speed | Impact of Faster Speed |

|---|---|---|

| Residence Time | Increases | Decreases |

| Heat Transfer | Slower, more uniform heating | Faster, more aggressive heating |

| Material Mixing | Gentler tumbling | More aggressive tumbling |

| Primary Goal | Maximizes product quality | Maximizes system throughput |

Ready to achieve precise control over your thermal processing?

Adjustable speed is key to optimizing your rotary kiln for maximum efficiency and product quality. Backed by expert R&D and manufacturing, KINTEK offers Rotary, Muffle, Tube, Vacuum, and CVD furnace systems, all customizable for your unique material and production needs.

Contact our experts today to discuss how a custom-engineered kiln or furnace can transform your operations.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results