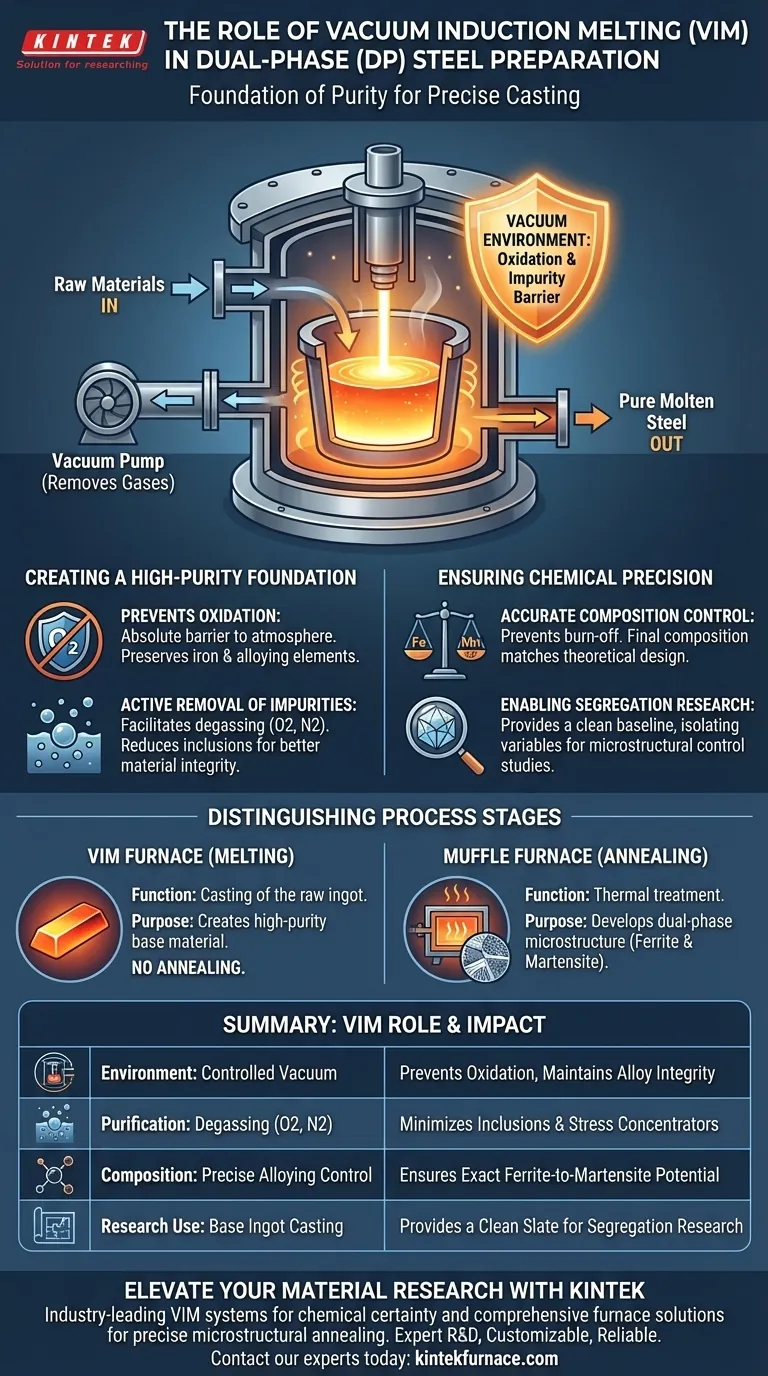

The Vacuum Induction Melting (VIM) furnace serves as the foundational processing unit for the preparation of Dual-Phase (DP) steel, specifically utilized for the precise casting of steel ingots. By operating within a vacuum environment, this furnace prevents the oxidation of the melt and actively removes gas impurities, ensuring the base material meets exact chemical specifications.

Core Takeaway: The VIM furnace is not merely a melting tool; it is a purification system. Its ability to eliminate oxidation and gas impurities creates a chemically precise "clean slate," which is a prerequisite for conducting accurate research into segregation neutralization and microstructural control.

Creating a High-Purity Foundation

The preparation of high-quality Dual-Phase steel begins with the quality of the initial ingot. The VIM furnace addresses the most critical risks present during the melting phase.

Prevention of Melt Oxidation

Standard melting processes expose molten steel to oxygen, leading to the formation of oxides that degrade material quality.

The VIM furnace operates in a vacuum environment, acting as an absolute barrier between the melt and the atmosphere. This prevents the oxidation of the iron and critical alloying elements, preserving the integrity of the mix.

Active Removal of Impurities

Beyond preventing new oxidation, the VIM process actively cleans the material.

The vacuum conditions facilitate the removal of volatile gas impurities, such as oxygen and nitrogen. Reducing these inclusions is vital, as they can act as stress concentrators or interfere with the intended phase transformations in DP steel.

Ensuring Chemical Precision

For Dual-Phase steel, the mechanical properties rely heavily on the precise ratio of ferrite to martensite. This ratio is dictated by the chemical composition established during the melting stage.

Accurate Composition Control

Because the vacuum environment prevents alloying elements from burning off or oxidizing, the final chemical composition remains highly consistent with the input materials.

This ensures that the experimental steel matches the theoretical design, providing a reliable baseline for subsequent testing.

Enabling Segregation Research

The primary reference highlights that VIM-prepared ingots are used specifically for research into segregation neutralization strategies.

By guaranteeing a high-quality base material with no unexpected impurities, researchers can isolate variables. This allows them to attribute changes in performance directly to their experimental strategies rather than defects in the casting.

Distinguishing the Process Stages

It is critical to distinguish between the preparation of the steel and the treatment of the steel, as different equipment is required for each.

Melting vs. Annealing

The VIM furnace is used solely for the casting of the ingot. It creates the raw material.

It does not perform the annealing treatment required to develop the dual-phase microstructure (ferrite and martensite). As noted in the supplementary data, a Laboratory Muffle Furnace is typically used later in the process to regulate martensite volume fraction through precise heating curves.

Making the Right Choice for Your Goal

To ensure the success of your Dual-Phase steel development, apply the equipment based on your specific process stage:

- If your primary focus is Material Synthesis: Use the VIM furnace to ensure your base ingots are free of inclusions and chemically accurate, preventing data skewing in later stages.

- If your primary focus is Microstructural Control: Recognize that while the VIM furnace provides the necessary purity, the actual phase transformation (martensite formation) must be managed separately in an annealing furnace.

The VIM furnace provides the chemical certainty required to make all subsequent thermal treatments and structural analysis valid.

Summary Table:

| Feature | VIM Furnace Role in DP Steel Preparation | Impact on Material Quality |

|---|---|---|

| Environment | Controlled Vacuum | Prevents oxidation and maintains alloy integrity |

| Purification | Degassing (O2, N2 removal) | Minimizes inclusions and stress concentrators |

| Composition | Precise Alloying Control | Ensures exact ferrite-to-martensite potential |

| Research Use | Base Ingot Casting | Provides a clean slate for segregation research |

Elevate Your Material Research with KINTEK

Precise Dual-Phase steel development demands a foundation of absolute purity. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems alongside a comprehensive range of Laboratory Muffle, Tube, and Vacuum furnaces designed to transition your research from high-purity casting to precise microstructural annealing.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems are engineered for chemical precision and gas impurity removal.

- Customizable Solutions: Whether you need a VIM system for material synthesis or a Muffle furnace for phase transformation, we tailor equipment to your unique lab specifications.

- End-to-End Reliability: Backed by technical expertise to ensure your experimental data is never skewed by impurities.

Ready to achieve chemical certainty? Contact our experts today to find the perfect furnace solution for your DP steel research.

Visual Guide

References

- Pedram Dastur, Claire Davis. Development of a High Ductility DP Steel Using a Segregation Neutralization Approach: Benchmarked Against a Commercial Dual Phase Steel. DOI: 10.1007/s11661-024-07427-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What is the primary objective of using a VIM furnace in magnet production? Ensure Purity and Homogeneity

- What is the primary function of an arc melting furnace? Master Homogenization of Fe-based Alloy Ingots

- What is an induction-heated vacuum furnace and what is its primary use? Achieve Ultimate Metal Purity for High-Performance Alloys

- Why is an argon atmosphere maintained during VIM of Chromium-Silicon alloys? Prevent High Chromium Loss

- Why is a vacuum induction furnace necessary for Seebeck coefficient measurement? Achieve Precise Thermal Data

- What are the benefits of the compact and lightweight design of induction furnaces? Maximize Efficiency in Limited Space

- What advantages do induction furnaces offer for aluminum melting? Boost Speed, Purity, and Efficiency