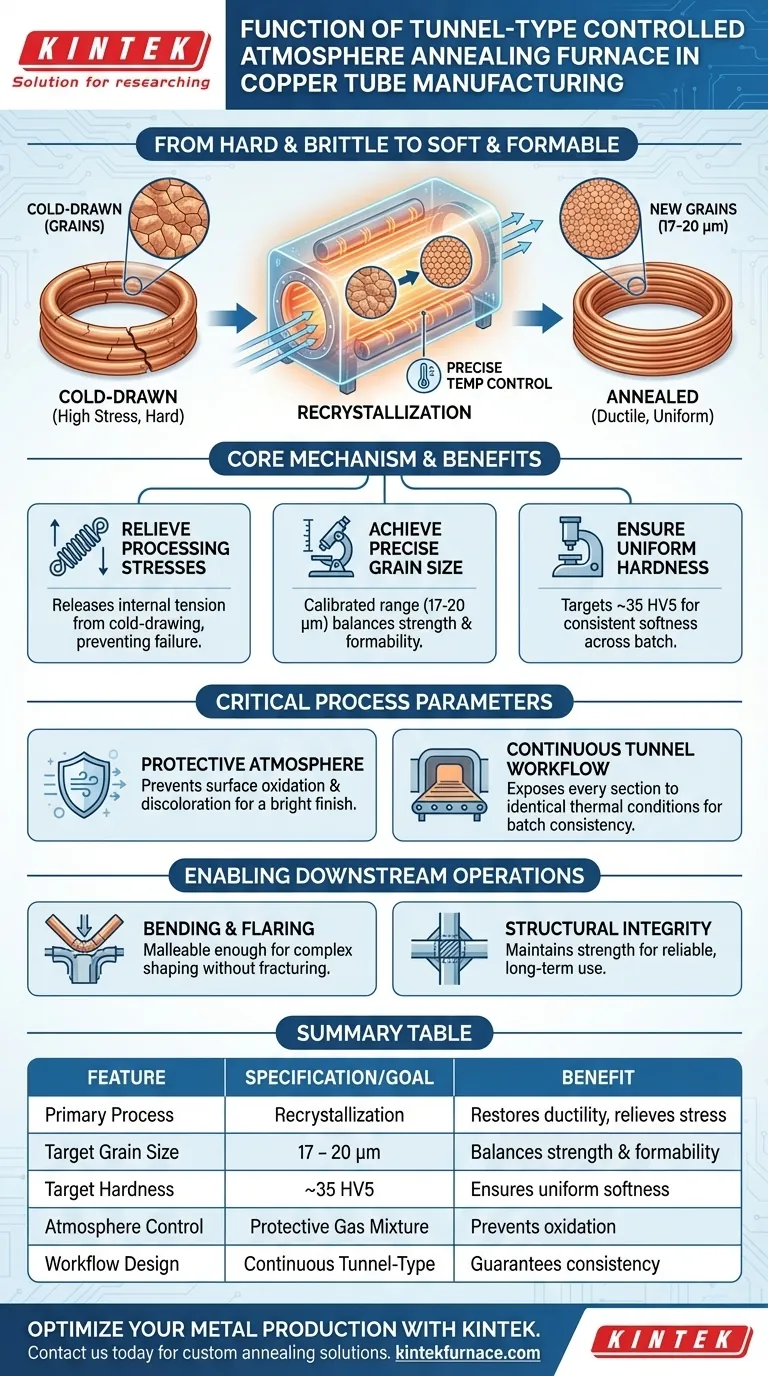

The function of a tunnel-type controlled atmosphere annealing furnace is to restore ductility to cold-drawn copper tubes through precise recrystallization. This continuous thermal process relieves internal stresses caused by previous manufacturing steps and modifies the metal's internal structure. By maintaining a specific protective atmosphere, it ensures the tubes achieve uniform softness without surface oxidation, preparing them for complex mechanical shaping.

Core Takeaway Cold drawing makes copper hard and brittle; this furnace reverses that effect to prevent cracking during installation or fabrication. By controlling grain size and hardness within tight tolerances, the furnace ensures the material becomes malleable enough for bending and flaring while maintaining structural integrity.

The Mechanism of Recrystallization

Relieving Processing Stresses

During the cold-drawing process, copper tubes are stretched and compressed, creating significant internal tension. This makes the material hard but prone to failure under further stress. The primary function of the annealing furnace is to heat the material sufficiently to release these accumulated processing stresses.

Formation of New Grains

The heat treatment triggers recrystallization, a process where deformed grains in the metal structure are replaced by a new set of defect-free grains. This microstructural reset is essential for transforming the physical properties of the copper from rigid to flexible.

Precise Grain Size Control

Controlling the size of these new grains is critical for performance. The furnace is calibrated to maintain a grain size typically between 17 and 20 µm. Keeping the grains within this specific range ensures the optimal balance between strength and formability.

Ensuring Material Uniformity

Achieving Consistent Hardness

A key output of this process is the reduction of hardness to a uniform level across the entire batch. The furnace typically targets a hardness value of approximately 35 HV5. This specific level of softness allows the copper to be worked easily without fracturing.

Enabling Mechanical Operations

The restoration of ductility is not an end in itself; it is a requirement for downstream manufacturing. Because of this annealing process, the copper tubes can successfully undergo rigorous mechanical operations, such as bending and flaring, which would shatter untreated, cold-drawn copper.

Continuous Batch Consistency

The "tunnel-type" design facilitates a continuous workflow rather than a static batch process. This ensures that every section of the copper tubing is exposed to identical thermal conditions, resulting in uniform properties throughout the entire production run.

Critical Process Parameters

The Role of Protective Atmosphere

The "controlled atmosphere" aspect is vital to maintaining surface quality. By surrounding the copper with a protective gas mixture during heating, the furnace prevents oxygen from reacting with the hot metal. This ensures the tubes emerge bright and clean, rather than oxidized or discolored.

Temperature Stability

To achieve the specific grain size (17–20 µm) and hardness (35 HV5) mentioned above, temperature stability is non-negotiable. Fluctuations in the furnace temperature would lead to inconsistent grain growth, resulting in sections of tubing that are either too soft or too brittle.

Making the Right Choice for Your Goal

When evaluating the annealing process for copper tubing, focus on the specific mechanical requirements of your final application.

- If your primary focus is intricate shaping (Bending/Flaring): Ensure the process strictly verifies the grain size is kept between 17 and 20 µm to maximize ductility.

- If your primary focus is material consistency: Verify that the furnace achieves a uniform hardness of ~35 HV5 to prevent weak spots in long production runs.

Ultimately, the value of this furnace lies in its ability to turn rigid, stressed copper into a reliable, formable component ready for industrial use.

Summary Table:

| Feature | Specification/Goal | Benefit |

|---|---|---|

| Primary Process | Recrystallization | Restores ductility and relieves internal stress |

| Target Grain Size | 17 - 20 µm | Balances material strength and formability |

| Target Hardness | ~35 HV5 | Ensures uniform softness for bending and flaring |

| Atmosphere Control | Protective Gas Mixture | Prevents surface oxidation and discoloration |

| Workflow Design | Continuous Tunnel-Type | Guarantees batch consistency and thermal uniformity |

Optimize Your Metal Production with KINTEK

Don't let brittle materials stall your manufacturing. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your specific thermal processing needs. Whether you are aiming for precise grain size control or oxidation-free finishes, our lab and industrial furnaces provide the stability your high-temp applications demand.

Ready to enhance your lab's efficiency and material quality? Contact KINTEK today to consult with our experts on the perfect annealing solution for your unique requirements.

Visual Guide

References

- Zeynep Sirel, Mehmet Ali Akoy. Influence of Phosphorus Content and Preheating Conditions on Grain Size of Cu-DHP Copper Tubes. DOI: 10.34088/kojose.1475031

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What core processing conditions does a tube atmosphere furnace provide? Key Factors for fMC Carbonization

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the design configurations of retort furnaces? Optimize Your Thermal Processing with the Right Setup

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- What are the technical advantages of a Zero-reforming Vertical Furnace? Revolutionize Green DRI Production Today

- How does an atmosphere box furnace support the synthesis of new energy materials? Unlock Precise Control for High-Performance Materials

- What are endothermic atmospheres and how are they produced? Master Precise Heat Treatment for Metals

- What role does atmosphere control play in ruthenium loading for catalyst synthesis? Master Precision Kinetics