At its core, a retort furnace's design is defined by two primary factors: its physical orientation and its heating method. These fundamental choices dictate how the furnace operates, what processes it excels at, and how it integrates into a workflow, with the most common configurations being horizontal or vertical and heated by either electric elements or gas burners.

The optimal retort furnace configuration is not a matter of preference but a direct consequence of your process needs. The decision between horizontal, vertical, electric, or gas designs hinges on your specific requirements for material handling, floor space, atmospheric control, and temperature precision.

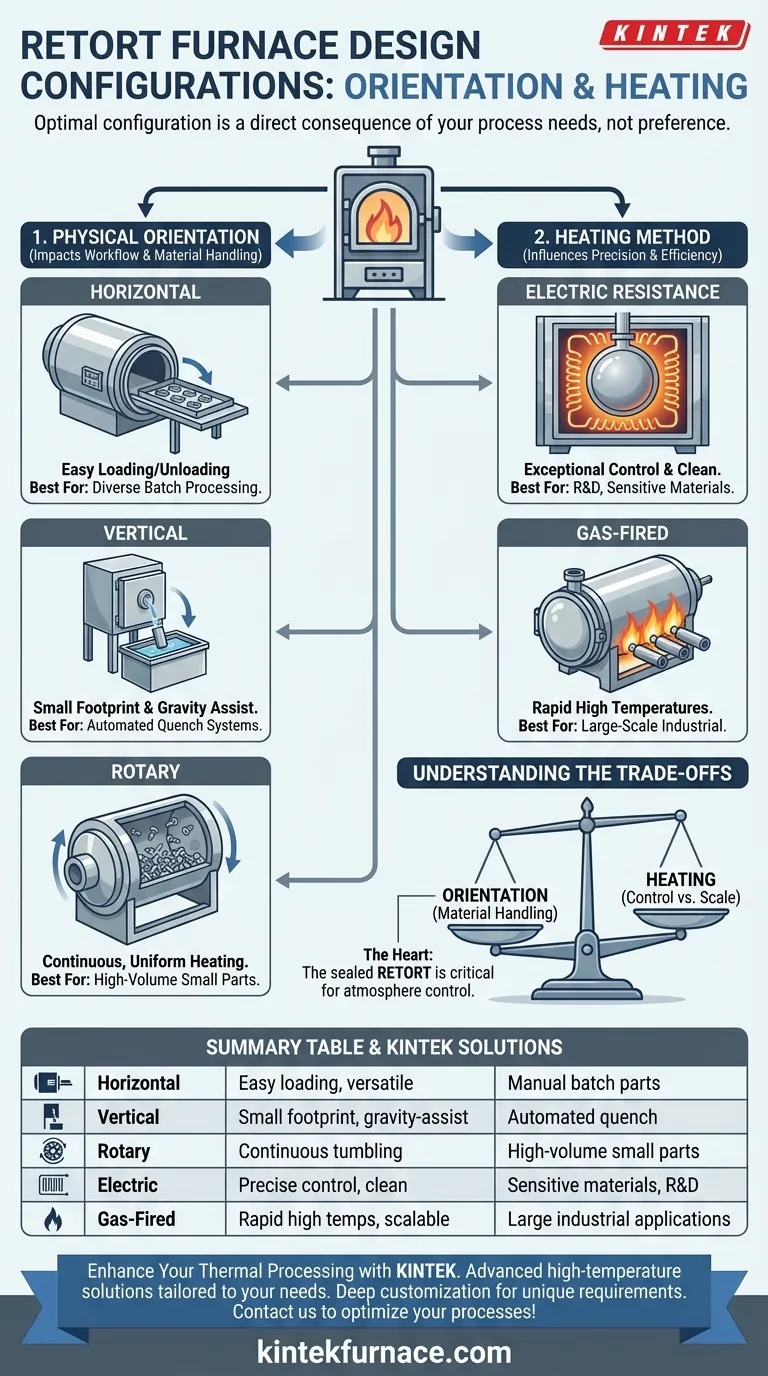

The Primary Configuration: Furnace Orientation

The physical layout of the furnace is the most visible design choice. This determines how material is loaded, processed, and unloaded, directly impacting workflow efficiency and the types of parts that can be treated.

The Horizontal Retort Furnace

A horizontal retort furnace orients the sealed chamber parallel to the ground. This is a common and highly versatile configuration.

Its primary advantage is ease of loading and unloading. Operators can easily place parts, trays, or fixtures into the chamber manually or with simple loading equipment, making it ideal for batch processing of various part sizes.

The Vertical Retort Furnace

In a vertical design, the chamber is oriented upright. This configuration offers two distinct benefits: a smaller footprint and the ability to leverage gravity.

Vertical furnaces are excellent for facilities with limited floor space. Furthermore, they are perfectly suited for gravity-assisted processes, where parts can be dropped from the hot zone directly into a quench tank below for rapid cooling.

The Rotary Retort Furnace

This is a specialized variation, typically horizontal, that features a slowly rotating cylindrical retort. This design is not for static batch processing.

Instead, it provides continuous, uniform heating for a high volume of small parts, such as fasteners or bearings. The tumbling action ensures every surface of each part is exposed to the controlled atmosphere and temperature, making it ideal for processes like continuous annealing or quench hardening.

The Critical Choice: Heating Method

How the furnace generates heat is just as critical as its orientation. The heating method directly influences temperature uniformity, control precision, and operational efficiency.

Electric Resistance Heating

Most modern laboratory and high-precision industrial retort furnaces use electric resistance heaters. These elements surround the retort to provide heat.

The key benefit is exceptional temperature control and uniformity. Electric heating is clean, quiet, and allows for very precise programming of heating and cooling cycles, which is essential for sensitive materials, scientific experiments, and processes like furnace brazing.

Gas-Fired Heating

In some large-scale industrial applications, gas burners are used as the heat source. These burners heat the exterior of the retort.

Gas-fired systems can achieve very high temperatures rapidly and can sometimes be more cost-effective to operate at a massive scale compared to electricity. However, achieving the same level of temperature uniformity as an electric system can be more challenging.

Understanding the Trade-offs

Selecting a retort furnace involves balancing competing priorities. Each design choice comes with inherent advantages and disadvantages that must be weighed against your specific application.

Horizontal vs. Vertical: A Matter of Process Flow

The choice between horizontal and vertical is fundamentally a question of material handling. Horizontal designs are simpler for manual or semi-automated batch work. Vertical designs excel when integrated into automated, top-loading, or bottom-unloading systems, especially those involving a quench.

Electric vs. Gas: Control vs. Scale

This decision balances precision against operational scale. Electric heating offers unparalleled control, making it the standard for research, electronics, and aerospace applications. Gas firing provides raw power for high-volume, heavy industrial processes where minor temperature fluctuations are acceptable.

The Importance of the Retort

Regardless of configuration, the heart of the furnace is the retort itself. This sealed vessel contains the special atmosphere (e.g., nitrogen, argon, hydrogen) and isolates the workload from the heating elements and outside air. The retort's material—typically a high-nickel alloy or ceramic—is a critical design choice that dictates the furnace's maximum temperature and chemical compatibility.

Matching the Furnace to Your Process

Choosing the right design configuration is a matter of aligning the furnace's strengths with your primary objective.

- If your primary focus is easy manual loading of diverse parts in batches: A horizontal, electrically heated furnace provides the best combination of flexibility and control.

- If your primary focus is conserving floor space or integrating a gravity-drop quench: A vertical furnace is the superior choice.

- If your primary focus is high-volume, continuous processing of small, uniform parts: A rotary retort furnace is the most efficient solution.

- If your primary focus is high-purity processing or R&D with sensitive materials: An electrically heated furnace is non-negotiable for its precision and clean operation.

By understanding these core design principles, you can select a retort furnace that functions as a precision tool engineered for your specific thermal processing goal.

Summary Table:

| Configuration Type | Key Features | Best For |

|---|---|---|

| Horizontal | Easy loading/unloading, versatile for batch processing | Manual handling of diverse parts |

| Vertical | Small footprint, gravity-assisted processes | Space-saving, automated quench systems |

| Rotary | Continuous, uniform heating, tumbling action | High-volume small parts like fasteners |

| Electric Heating | Precise temperature control, clean operation | Sensitive materials, R&D, high-purity processes |

| Gas-Fired Heating | Rapid high temperatures, cost-effective at scale | Large industrial applications with less precision needs |

Ready to enhance your lab's thermal processing capabilities? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet unique experimental requirements. Whether you're in research, electronics, or heavy industry, we can help you achieve superior temperature control and efficiency. Contact us today to discuss how our retort furnaces can optimize your processes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments