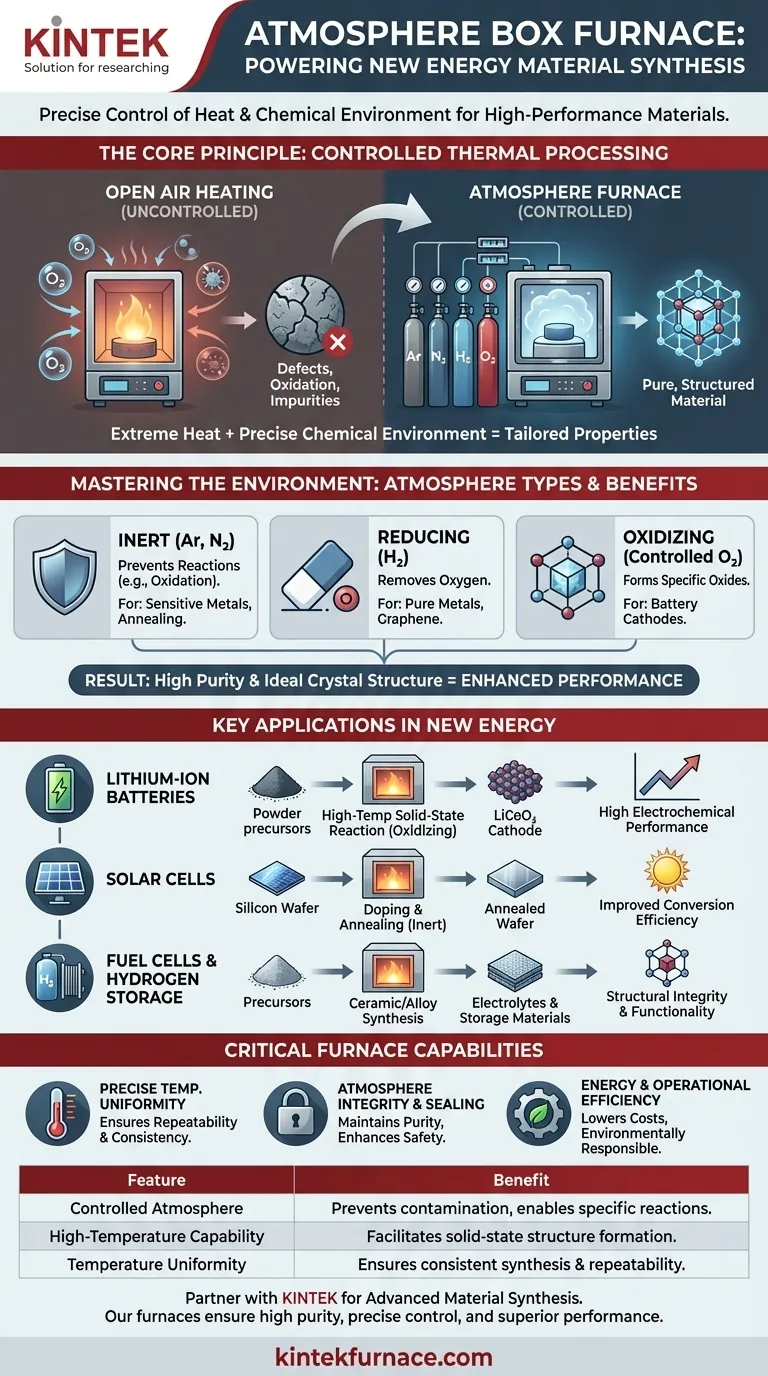

At its core, an atmosphere box furnace supports the synthesis of new energy materials by providing the two conditions essential for their creation: extreme heat and a precisely controlled chemical environment. This combination allows for high-temperature reactions that form the specific crystal structures and chemical compositions required for materials in batteries, solar cells, and fuel cells, while preventing contamination or unwanted side reactions from the ambient air.

The true value of an atmosphere furnace is not just its ability to get hot, but its power to dictate the exact chemical environment in which a material is formed. This atmospheric control is the key that unlocks the synthesis of high-performance materials with specific, tailored properties.

The Core Principle: Controlled Thermal Processing

The synthesis of advanced materials is a delicate process. Simply heating precursor materials in open air is often counterproductive, leading to defects, impurities, and poor performance. An atmosphere furnace solves this by mastering the processing environment.

Why Heat Isn't Enough

At high temperatures, most materials become highly reactive. When exposed to ambient air—which is roughly 21% oxygen—metals will oxidize, organic compounds will combust, and sensitive crystal structures can become contaminated.

This means that without atmospheric control, you are not creating the pure, high-performance material you intended. Instead, you are creating an uncontrolled mixture of oxides and other undesirable byproducts.

The Role of a Controlled Atmosphere

An atmosphere furnace replaces the ambient air in its chamber with a specific gas or gas mixture. This allows scientists and engineers to create the ideal chemical environment for a specific reaction.

Common atmospheres include:

- Inert: Using gases like Argon or Nitrogen to prevent any chemical reactions, especially oxidation. This is critical for processing sensitive metals or annealing materials without changing their chemistry.

- Reducing: Using gases like Hydrogen to actively remove oxygen from a material. This is used to create pure metals from their oxides or to synthesize certain carbon materials like graphene.

- Oxidizing: Using a controlled amount of Oxygen to intentionally form a specific oxide structure, which is essential for many battery cathode materials.

Achieving Material Purity and Structure

By preventing unwanted side reactions, the controlled atmosphere ensures the final product achieves high purity.

Furthermore, it allows for the formation of the desired crystallinity—the ordered, repeating arrangement of atoms in a solid. A well-defined crystal structure is directly linked to a material's performance, such as how efficiently ions move in a battery or electrons move in a solar cell.

Key Applications in New Energy Material Synthesis

The precise control offered by these furnaces makes them indispensable across the new energy sector.

For Lithium-Ion Batteries

The performance of a lithium-ion battery is largely determined by its cathode material. These are typically complex metal oxides, such as Lithium Cobalt Oxide (LiCoO2).

An atmosphere furnace is used to perform a high-temperature solid-state reaction, heating precursor powders in a precisely controlled oxygen atmosphere to form the exact crystal structure needed for excellent electrochemical performance.

For Solar Cells

In solar cell manufacturing, silicon wafers undergo processes like doping (introducing impurities to change electrical properties) and annealing (heating to relieve stress and repair crystal defects).

Performing these steps in an atmosphere furnace under an inert atmosphere prevents the formation of a performance-killing oxide layer on the silicon surface, directly improving the cell's photoelectric conversion efficiency.

For Fuel Cells and Hydrogen Storage

These furnaces are also critical for preparing materials central to other green technologies. This includes synthesizing ceramic electrolyte materials for solid oxide fuel cells and creating novel alloys and compounds for hydrogen storage.

In both cases, the ability to control the reaction environment at high temperatures is essential to produce materials with the required structural integrity and functional properties.

Understanding Key Furnace Capabilities

Not all furnaces are created equal. When evaluating or using an atmosphere furnace for material synthesis, several operational factors are critical for success and efficiency.

Precise Temperature Uniformity

For a process to be repeatable and scalable, every part of the material batch must experience the exact same temperature. Excellent thermal homogeneity ensures that the entire sample is synthesized uniformly, preventing inconsistencies in the final product.

Atmosphere Integrity and Sealing

The effectiveness of an atmosphere furnace hinges on its ability to maintain the purity of the internal gas. A high-quality seal is non-negotiable, as it prevents air from leaking in and contaminating the process, while also minimizing the waste of expensive process gases.

Energy and Operational Efficiency

Modern furnaces utilize advanced heating elements and superior insulation to minimize heat loss. This improves energy efficiency, reducing operational costs. Effective sealing also minimizes gas emissions, supporting safer and more environmentally responsible lab operations.

Making the Right Choice for Your Goal

The specific atmosphere and process you choose are dictated entirely by the chemistry of the material you are synthesizing.

- If your primary focus is oxide-based materials (e.g., battery cathodes, ceramics): You require precise control over an oxidizing atmosphere to form the correct chemical structure.

- If your primary focus is non-oxide materials (e.g., metal alloys, graphene, wafer annealing): You must use an inert or reducing atmosphere to prevent oxidation and ensure material purity.

- If your primary focus is process repeatability and quality control: Prioritize a furnace with certified temperature uniformity and automated, leak-proof atmosphere management systems.

Ultimately, the atmosphere box furnace is more than just a source of heat; it is an indispensable instrument for precisely engineering the materials that will power our future.

Summary Table:

| Feature | Benefit |

|---|---|

| Controlled Atmosphere | Prevents contamination and enables specific chemical reactions (e.g., inert, reducing, oxidizing) |

| High-Temperature Capability | Facilitates solid-state reactions for crystal structure formation |

| Temperature Uniformity | Ensures consistent material synthesis and repeatability |

| Atmosphere Integrity | Maintains gas purity, reducing waste and improving safety |

| Energy Efficiency | Lowers operational costs with advanced insulation and heating |

Ready to enhance your new energy material synthesis with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're working on batteries, solar cells, or fuel cells, our furnaces ensure high purity, precise control, and superior performance. Contact us today to discuss how we can support your innovative projects and drive your research forward!

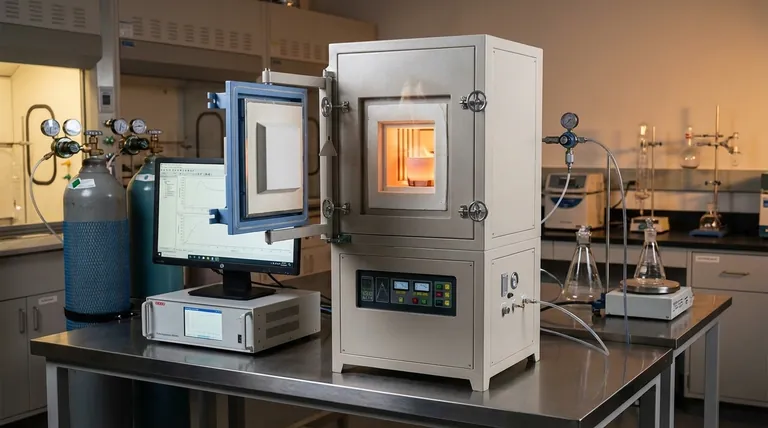

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation