In short, atmosphere furnaces create a chemically controlled environment essential for the high-temperature processing of ceramics. During critical stages like sintering and firing, this control prevents unwanted reactions with the air, which would otherwise compromise the material's purity, strength, and final performance characteristics.

The crucial function of an atmosphere furnace is not just to provide heat, but to master the chemical environment in which the ceramic is formed. This control is what allows manufacturers to transform raw powders into dense, pure, and structurally sound components with highly specific properties.

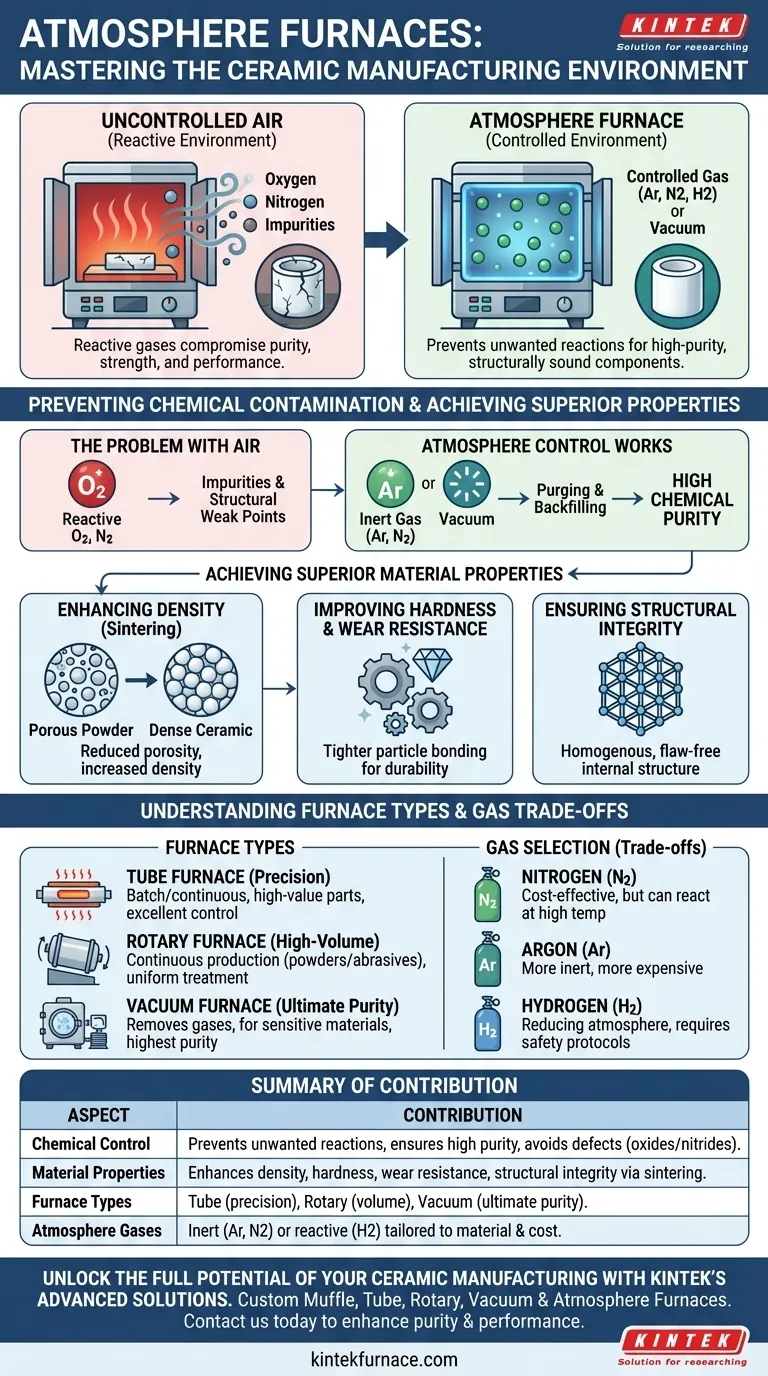

The Core Principle: Preventing Chemical Contamination

The primary purpose of an atmosphere furnace is to eliminate the variable and destructive influence of ambient air during high-temperature ceramic processing.

The Problem with Air

At the high temperatures required for sintering (often exceeding 1000°C), the oxygen and nitrogen in the air become highly reactive. These gases can readily form unwanted oxides and nitrides within the ceramic material, creating impurities that act as structural weak points.

How Atmosphere Control Works

An atmosphere furnace replaces the ambient air with a specific, controlled gas or a vacuum. This is achieved by first purging the chamber and then backfilling it with a desired gas, such as an inert gas like argon or nitrogen, or a reactive gas like hydrogen for specific chemical purposes.

The Impact on Material Purity

By creating an inert or precisely controlled reactive environment, the furnace prevents the formation of these contaminants. This ensures the final ceramic product achieves its intended chemical purity, which is critical for applications in electronics, medical implants, and aerospace.

Achieving Superior Material Properties

Controlling the atmosphere directly translates to measurable improvements in the final ceramic part's physical and mechanical properties.

Enhancing Density Through Sintering

Sintering is the process where ceramic powder particles are heated to fuse together, reducing porosity and increasing density. A controlled atmosphere allows these particles to form strong, direct bonds without interference from oxidative reactions, resulting in a significantly denser and less porous final product.

Improving Hardness and Wear Resistance

The higher density and tight particle bonding achieved through controlled sintering directly lead to increased hardness and wear resistance. This is essential for components like cutting tools, bearings, and abrasive materials.

Ensuring Structural Integrity

Chemical impurities and voids from uncontrolled reactions act as stress concentrators, compromising the part's structural integrity. Atmosphere furnaces produce a more homogenous and flaw-free internal structure, making the final component stronger and more reliable under mechanical or thermal stress.

Understanding Furnace Types and Trade-offs

The choice of furnace and atmosphere involves trade-offs between process requirements, material compatibility, and cost.

Tube vs. Rotary Furnaces

Tube furnaces are ideal for precise, batch-based processes or continuous processing of smaller parts. They offer excellent temperature uniformity and atmosphere control for high-value components.

Rotary furnaces are used for high-volume production, particularly for powders and abrasives. Their continuous rotation ensures every particle receives uniform heat treatment, guaranteeing consistent material properties across a large batch.

The Role of Vacuum

A vacuum furnace represents the ultimate level of atmosphere control by removing virtually all gases. This is used for the most sensitive materials where even trace amounts of an inert gas could be problematic. It offers the highest purity but is often a more complex and costly process.

Gas Selection and Cost

The choice of atmosphere gas is a critical decision. Nitrogen is a cost-effective choice for many ceramics, but it can react with certain materials at high temperatures. Argon is more inert but significantly more expensive. Hydrogen is used to create a "reducing" atmosphere to actively remove oxygen, but it requires stringent safety protocols.

How to Apply This to Your Goal

Your manufacturing goal will dictate the ideal furnace and atmosphere configuration.

- If your primary focus is maximum purity for advanced electronics: A vacuum furnace or a high-purity inert gas (argon) tube furnace is necessary to prevent any contamination.

- If your primary focus is high-volume production of ceramic powders: A rotary furnace will provide the thermal uniformity and throughput needed for consistent quality at scale.

- If your primary focus is cost-effective sintering of structural components: A furnace using a nitrogen atmosphere offers a good balance of chemical control and operational cost, provided the material is not reactive with nitrogen.

Ultimately, mastering the atmosphere inside the furnace is the key to unlocking the full performance potential of advanced ceramic materials.

Summary Table:

| Aspect | Contribution to Ceramic Manufacturing |

|---|---|

| Chemical Control | Prevents unwanted reactions with air, ensuring high purity and preventing defects like oxides and nitrides. |

| Material Properties | Enhances density, hardness, wear resistance, and structural integrity through controlled sintering processes. |

| Furnace Types | Tube furnaces for precision; Rotary furnaces for high volume; Vacuum for ultimate purity. |

| Atmosphere Gases | Inert gases (argon, nitrogen) or reactive gases (hydrogen) tailored to material needs and cost. |

Unlock the full potential of your ceramic manufacturing with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental requirements. Contact us today to enhance purity, performance, and efficiency in your lab!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling