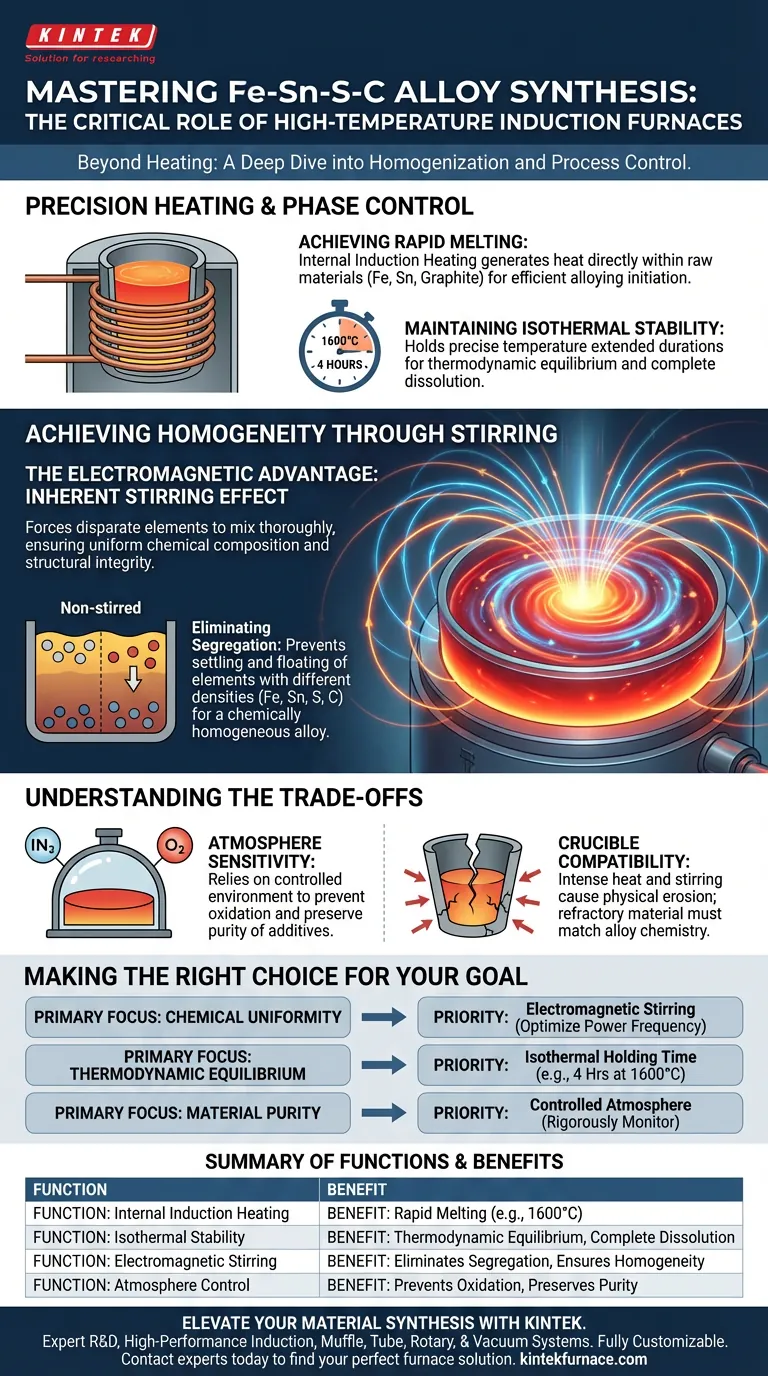

The high-temperature induction furnace acts as the critical processing vessel for synthesizing Fe-Sn-S-C alloys, serving functions far beyond simple heating. Its primary role is to rapidly melt the specific raw materials—electrolytic iron, tin particles, ferrous sulfide powder, and graphite powder—under a strictly controlled atmosphere. Crucially, it maintains precise isothermal conditions, such as holding the melt at 1600°C for extended periods (e.g., four hours), while utilizing electromagnetic forces to actively mix the alloy.

The Core Takeaway A high-temperature induction furnace does not just melt metal; it homogenizes it. Its defining advantage is the inherent electromagnetic stirring effect, which forces disparate elements to mix thoroughly, ensuring the final alloy has a uniform chemical composition and structural integrity.

Precision Heating and Phase Control

Achieving Rapid Melting

The induction furnace is specifically designed to bring materials to the liquid state quickly.

By inducing electrical currents directly within the conductive raw materials (iron, tin, graphite), it generates heat internally rather than relying on external radiation. This mechanism ensures that high melting points are reached efficiently, initiating the alloying process for the Fe-Sn-S-C system.

Maintaining Isothermal Stability

Creating a stable alloy requires more than just reaching a peak temperature; it requires thermal consistency.

For Fe-Sn-S-C alloys, the furnace must maintain a stable temperature of approximately 1600°C for durations as long as four hours. This extended holding time allows the various components to reach thermodynamic equilibrium, ensuring the complete dissolution of the graphite and sulfide powders into the iron matrix.

Achieving Homogeneity Through Stirring

The Electromagnetic Advantage

The most distinct function of an induction furnace is its electromagnetic stirring effect.

Unlike resistance furnaces (such as muffle or box furnaces) which provide static heat, the magnetic field in an induction furnace generates physical movement within the molten pool. This "stirring" action is automatic and continuous as long as the induction power is active.

Eliminating Segregation

Uniformity is the primary challenge in alloying elements with different densities, such as iron and tin.

The electromagnetic agitation continually circulates the melt, preventing heavier elements from settling and lighter elements from floating. This ensures that the Carbon (C) and Sulfur (S) are evenly distributed throughout the Iron (Fe) and Tin (Sn) matrix, resulting in a chemically homogeneous alloy.

Understanding the Trade-offs

Atmosphere Sensitivity

While the furnace provides excellent heat and stirring, it relies heavily on a controlled atmosphere to maintain purity.

If the protective atmosphere is compromised, active elements in the melt can react with oxygen. As seen in similar vacuum induction processes, failure to control the environment can lead to the loss of alloying elements or the formation of unwanted oxides, compromising the material's mechanical properties.

Crucible Compatibility

The intense heat and stirring action place significant stress on the furnace lining (crucible).

At 1600°C, the molten Fe-Sn-S-C alloy is highly reactive. The stirring action can increase the physical erosion of the crucible, potentially introducing non-metallic inclusions into the melt if the refractory material is not perfectly matched to the alloy's chemistry.

Making the Right Choice for Your Goal

To ensure the successful preparation of your alloy, consider these strategic priorities:

- If your primary focus is Chemical Uniformity: Rely on the electromagnetic stirring capability of the induction furnace; ensure the power frequency is set to optimize this agitation during the holding phase.

- If your primary focus is Thermodynamic Equilibrium: Prioritize the isothermal holding time (e.g., 4 hours at 1600°C) to allow full diffusion of carbon and sulfur into the iron lattice.

- If your primary focus is Material Purity: Rigorously monitor the controlled atmosphere, as induction stirring is ineffective against oxidation if the environment is not sealed or inert.

Success in preparing Fe-Sn-S-C alloys lies in leveraging the induction furnace not just as a heater, but as a precision mixer.

Summary Table:

| Function | Description | Benefit for Fe-Sn-S-C Alloys |

|---|---|---|

| Internal Induction Heating | Generates heat directly within conductive raw materials. | Rapidly reaches melting points (e.g., 1600°C) for iron and graphite. |

| Isothermal Stability | Maintains a constant temperature for extended durations. | Ensures thermodynamic equilibrium and complete dissolution of components. |

| Electromagnetic Stirring | Uses magnetic fields to physically circulate the melt. | Eliminates segregation of tin and iron, ensuring chemical homogeneity. |

| Atmosphere Control | Operates under vacuum or inert gas conditions. | Prevents oxidation and preserves the purity of carbon and sulfur additives. |

Elevate Your Material Synthesis with KINTEK

Precision in metallurgy demands more than just heat; it requires absolute control over homogenization and environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Induction, Muffle, Tube, Rotary, and Vacuum systems designed to meet the rigorous demands of alloy preparation.

Whether you are synthesizing complex Fe-Sn-S-C systems or developing next-generation ceramics, our lab high-temperature furnaces are fully customizable to your unique research needs. Ensure chemical uniformity and structural integrity in every melt.

Ready to optimize your alloying process? Contact our experts today to find your perfect furnace solution!

Visual Guide

References

- Hyunjae Kim, Youn‐Bae Kang. Evaporation of Sn from Molten Fe–C–S Alloy Under Reduced Pressure at 1650 $$^\circ $$C for Developing Sustainable Ferrous Scrap Recycling Process. DOI: 10.1007/s11663-025-03579-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a vacuum induction melting furnace required for microalloyed steel ingots? Ensure Experimental Precision

- Why are graphene induction coils able to maintain more stable heating rates? Achieve Precision at 2000°C+

- Can aluminium be melted in an induction furnace? Discover the Efficient, High-Quality Method

- What role does a Vacuum Induction Melting Furnace play in the production of weather-resistant steel? Precision Engineering

- What is the primary function of an arc-melting furnace in Cr0.82Mn0.18Ge synthesis? Achieve High-Purity Alloy Fusion

- What role does a vacuum induction melting furnace play in AHSS research? Master Purity in High-Strength Steel Ingots

- Why is the yield of inductive heating evaporation significantly higher than that of resistive heating? Maximize Your Evaporation Rate

- What are the fundamental principles behind induction heating? Unlock Efficient, Non-Contact Heat for Your Lab