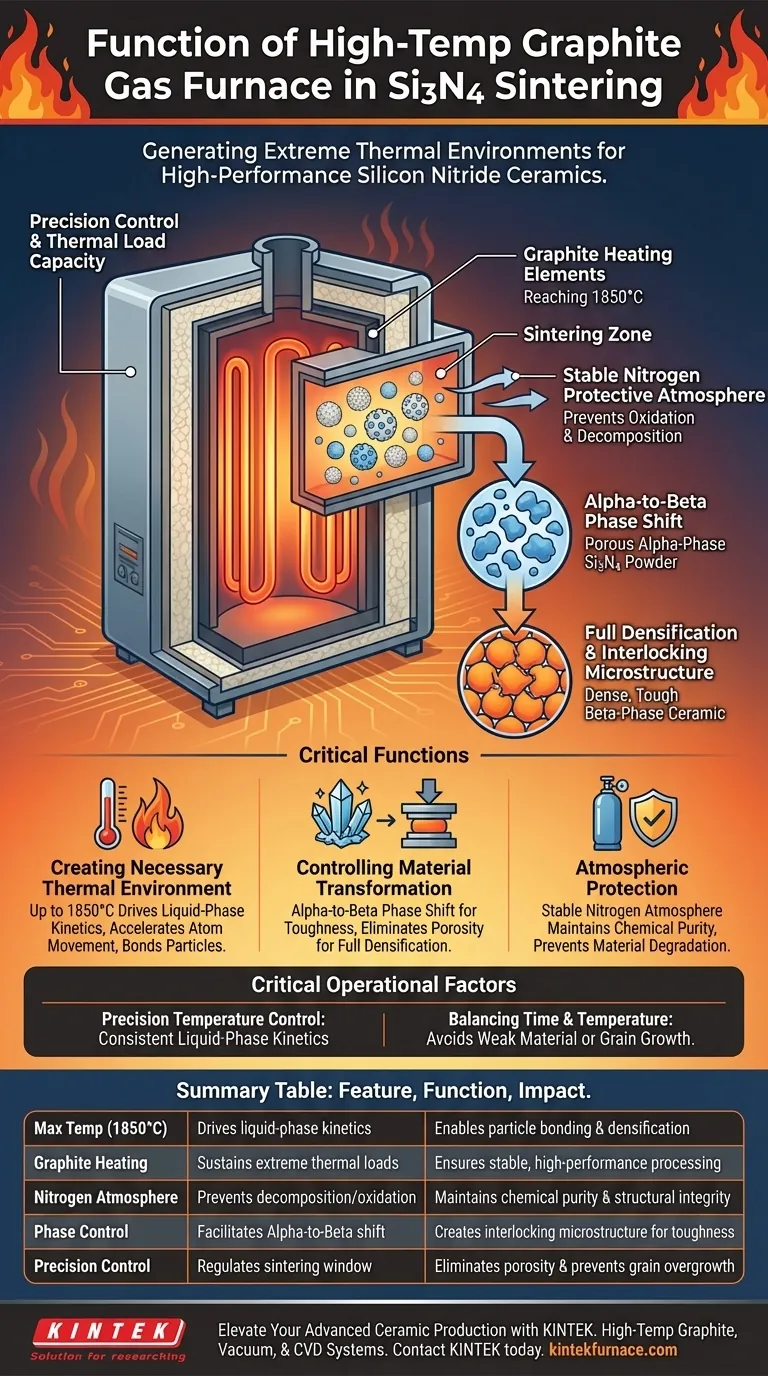

The primary function of a high-temperature graphite gas furnace is to generate the precise extreme thermal environment required to transform porous silicon nitride powder into a dense, high-performance ceramic. Specifically, it provides temperatures up to 1850°C within a stable nitrogen protective atmosphere to drive the sintering process.

Silicon nitride cannot achieve its necessary mechanical properties through heat alone; it requires a controlled microstructural evolution. This furnace enables the critical liquid-phase sintering kinetics that convert the material from the alpha-phase to the beta-phase, ensuring complete densification.

Creating the Necessary Thermal Environment

Reaching Extreme Temperatures

To process silicon nitride effectively, the furnace must reach and sustain temperatures up to 1850°C.

Standard furnaces cannot withstand this thermal load, necessitating the use of graphite heating elements and insulation capable of operating in this extreme range.

Driving Liquid-Phase Kinetics

The high heat is not merely for melting; it promotes liquid-phase sintering kinetics.

This mechanism accelerates the movement of atoms at the grain boundaries, allowing the particles to bond together efficiently.

Controlling Material Transformation

The Alpha-to-Beta Phase Shift

The most critical function of the furnace is enabling the complete transformation of silicon nitride from the alpha-phase to the beta-phase.

This crystallographic change is essential because the beta-phase morphology provides the interlocking microstructure responsible for the material's toughness.

Achieving Full Densification

Through precise temperature application, the furnace eliminates porosity within the material.

This results in material densification, which is directly correlated to the final mechanical strength and durability of the component.

The Role of Atmospheric Protection

Maintaining a Nitrogen Atmosphere

The furnace must maintain a stable nitrogen protective atmosphere throughout the heating cycle.

This prevents the silicon nitride from decomposing or reacting with oxygen at high temperatures, which would degrade the material's properties.

Critical Operational Factors

The Necessity of Precision

This process relies heavily on precise temperature control rather than just raw heat.

If the temperature fluctuates, the liquid-phase kinetics may become inconsistent, leading to incomplete phase transformation or uneven density.

Balancing Time and Temperature

The transition from alpha to beta phase is sensitive to the sintering window.

Insufficient time or temperature results in a weak, porous material, while excessive exposure can lead to exaggerated grain growth that reduces strength.

Making the Right Choice for Your Goal

To maximize the utility of a high-temperature graphite gas furnace, focus on the specific outcome you need for your application.

- If your primary focus is Maximum Mechanical Strength: Prioritize temperature stability at the upper range (near 1850°C) to ensure 100% conversion to the interlocking beta-phase.

- If your primary focus is Component Consistency: Ensure the furnace maintains a uniform nitrogen flow to prevent localized decomposition or surface defects.

Success in sintering silicon nitride depends entirely on the furnace's ability to synchronize extreme heat with atmospheric stability.

Summary Table:

| Feature | Function in Si3N4 Sintering | Impact on Material |

|---|---|---|

| Max Temp (1850°C) | Drives liquid-phase kinetics | Enables particle bonding & densification |

| Graphite Heating | Sustains extreme thermal loads | Ensures stable, high-performance processing |

| Nitrogen Atmosphere | Prevents decomposition/oxidation | Maintains chemical purity & structural integrity |

| Phase Control | Facilitates Alpha-to-Beta shift | Creates interlocking microstructure for toughness |

| Precision Control | Regulates sintering window | Eliminates porosity and prevents grain overgrowth |

Elevate Your Advanced Ceramic Production with KINTEK

Achieving the perfect alpha-to-beta phase transformation in silicon nitride requires more than just heat—it requires absolute precision. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized high-temperature Graphite, Vacuum, and CVD systems designed to meet the rigorous demands of Si3N4 sintering.

Whether you need custom dimensions or specific atmospheric controls, our lab furnaces provide the stability and uniformity your materials deserve. Contact KINTEK today to discuss your unique sintering requirements and discover how our customizable thermal solutions can optimize your mechanical properties and component consistency.

Visual Guide

References

- Masanori Horie, Rodney W. Trice. Slip casting porous silicon nitride for high‐temperature radar frequency radomes. DOI: 10.1111/ijac.70016

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the advantages of using a vacuum environment in sintering? Achieve Superior Purity and Strength

- What are the main components of a vacuum furnace's internal structure? Optimize Your Heat Treatment Process

- How does a precise temperature control system prevent Rubidium Chloride loss? Optimize Vacuum Distillation Yield

- Why is furnace brazing critical in modern manufacturing? Achieve Strong, Clean, and Complex Metal Assemblies

- What maintenance procedures are required for a vacuum heat treatment furnace? Ensure Peak Performance and Longevity

- What control options are available for vacuum annealing furnaces? Explore PLC, Modes, and Precision Control

- How does cooling speed affect the vacuum sintering process? Optimize Material Properties and Prevent Defects

- What is the value of laboratory-scale melting furnaces in researching micro-alloying elements for Medium-Manganese Steel?