At its core, using a vacuum for sintering provides an exceptionally pure environment that is impossible to achieve with atmospheric gases. This prevents unwanted chemical reactions like oxidation and contamination, while actively promoting the material densification process, resulting in components with superior purity, density, and mechanical strength.

The fundamental advantage of vacuum sintering is not just the removal of air, but the creation of an active environment that purifies the material and accelerates atomic diffusion. This transforms the process from simply heating a powder to fundamentally re-engineering its internal structure for optimal performance.

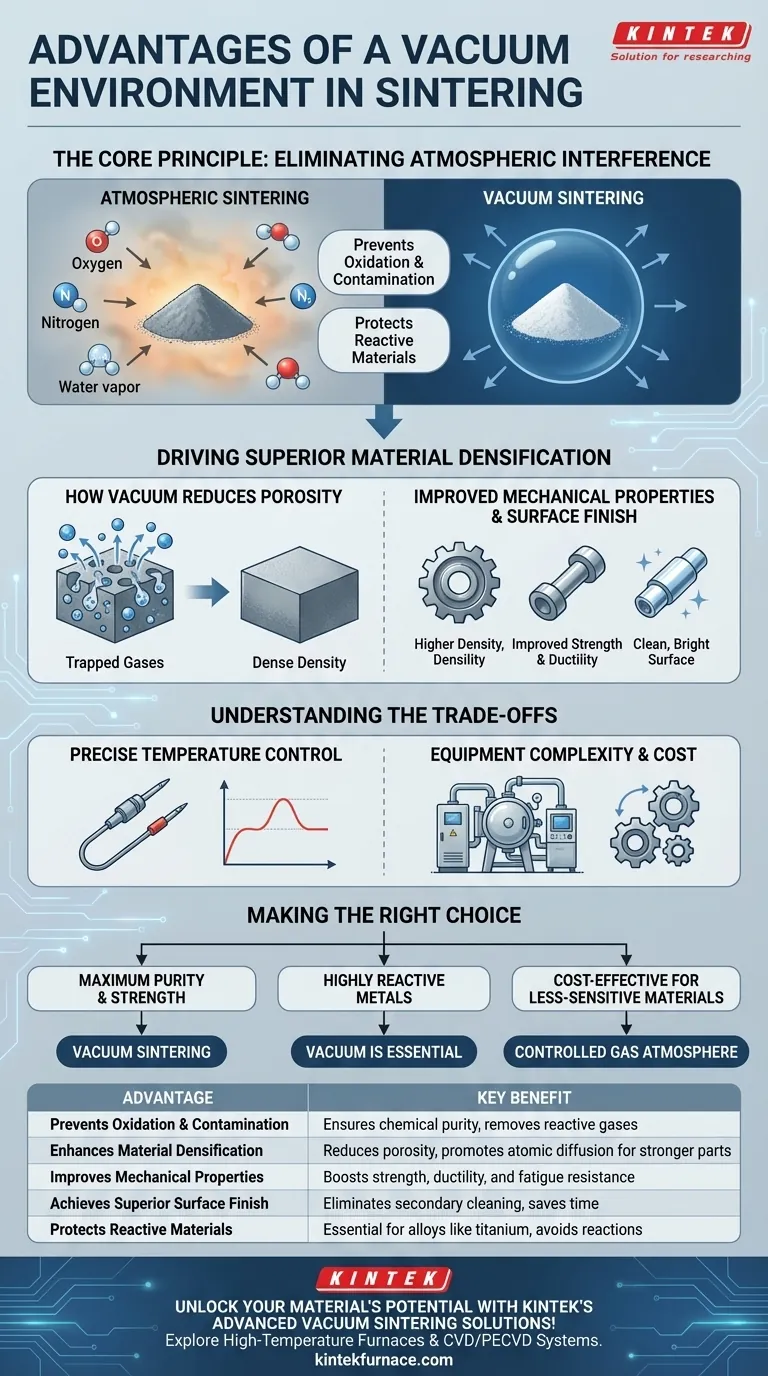

The Core Principle: Eliminating Atmospheric Interference

The primary function of the vacuum is to remove the reactive and unpredictable gases present in a normal atmosphere. This provides a stable, controlled foundation for the entire sintering process.

Preventing Oxidation and Contamination

Atmospheric air contains oxygen, nitrogen, water vapor, and other trace gases. At the high temperatures required for sintering, these components readily react with most materials, forming oxides and nitrides that act as impurities.

A vacuum environment removes these reactants. This preserves the chemical purity of the base material, which is critical for achieving the desired final properties in high-performance alloys, ceramics, and composites.

Protecting Reactive and Specialty Materials

Some advanced materials are so reactive that even a so-called "inert" gas atmosphere is insufficient. For example, certain alloys are prone to decarburization or carburization when trace hydrocarbons or carbon monoxide are present.

Vacuum is the ultimate inert environment, preventing these subtle but detrimental side reactions. This makes it essential for processing materials like titanium, refractory metals, and certain stainless steels.

Driving Superior Material Densification

Beyond preventing contamination, a vacuum actively aids in the consolidation of the powdered material into a solid, dense part.

How Vacuum Reduces Porosity

As the material heats up, gases trapped within the pores of the powdered compact expand. A vacuum environment creates a pressure differential, effectively pulling these trapped gases out of the part.

Removing this internal gas pressure allows the material particles to bond more effectively. This process, known as atomic diffusion, is greatly facilitated, leading to the collapse of internal voids and a significant reduction in porosity.

The Impact on Mechanical Properties

A direct result of reduced porosity is higher density. A denser part is a stronger part.

By eliminating internal defects and pores, vacuum sintering produces components with significantly improved strength, ductility, and fatigue resistance. These optimized mechanical properties are often the primary goal of the entire manufacturing process.

Achieving a Superior Surface Finish

Because vacuum prevents surface oxidation, the finished part emerges from the furnace clean and bright. This often reduces or eliminates the need for secondary operations like sandblasting, grinding, or chemical cleaning, saving both time and cost.

Understanding the Trade-offs and Process Demands

While powerful, vacuum sintering is a sophisticated process with specific requirements that must be managed for success.

The Need for Precise Temperature Control

The sintering process operates in a very narrow temperature window. The goal is to heat the material enough for atoms to diffuse and bond, but not so high that the material begins to liquefy.

Modern vacuum furnaces use advanced thermocouple systems and optimized heating elements to ensure uniform furnace temperature. This precise control is critical to achieving consistent, high-quality results.

Equipment Complexity and Cost

Vacuum furnaces are complex systems. They require robust vacuum pumps, water-cooled chambers to manage heat, and sophisticated automation and safety interlocks.

This level of technology represents a higher initial capital investment compared to conventional atmospheric furnaces. The decision to use vacuum sintering must be justified by the need for superior material properties that other methods cannot deliver.

Making the Right Choice for Your Goal

Selecting the correct sintering environment depends entirely on the material requirements and project goals.

- If your primary focus is maximum purity and mechanical strength: Vacuum sintering is the definitive choice for creating dense, clean, high-performance parts.

- If your primary focus is processing highly reactive metals: Vacuum is non-negotiable to prevent the formation of oxides, nitrides, or other detrimental reactions.

- If your primary focus is cost-effectiveness for less-sensitive materials: A controlled gas atmosphere (e.g., nitrogen, argon, or hydrogen) may provide sufficient protection for many standard metals and applications.

Ultimately, mastering the sintering environment is the key to unlocking the full potential of your material.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Prevents Oxidation & Contamination | Ensures chemical purity by removing reactive gases like oxygen and water vapor |

| Enhances Material Densification | Reduces porosity and promotes atomic diffusion for stronger, denser parts |

| Improves Mechanical Properties | Boosts strength, ductility, and fatigue resistance in final components |

| Achieves Superior Surface Finish | Eliminates need for secondary cleaning, saving time and costs |

| Protects Reactive Materials | Essential for alloys like titanium to avoid decarburization and other reactions |

Unlock the full potential of your materials with KINTEK's advanced vacuum sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior purity, density, and mechanical strength for high-performance parts. Contact us today to discuss how we can optimize your sintering process and achieve outstanding results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments