The essential maintenance for a vacuum heat treatment furnace is a disciplined, multi-faceted process. It involves the regular inspection, cleaning, and scheduled replacement of components across the vacuum chamber, heating system, pumping system, and cooling system to ensure the integrity of the controlled environment.

Effective maintenance is not merely about preventing equipment failure. It is the fundamental practice that preserves the core benefits of a vacuum furnace—process purity, temperature uniformity, and part quality—ensuring consistent, high-value output.

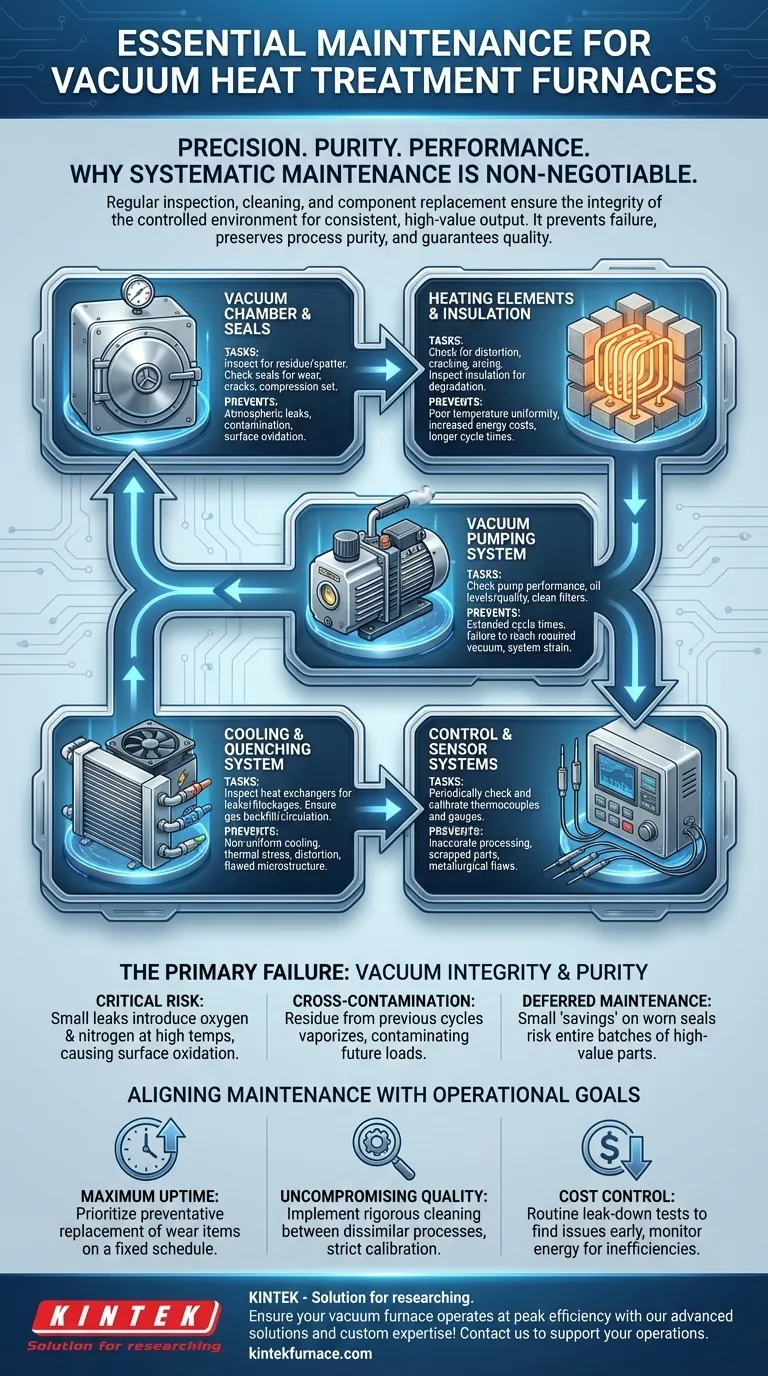

Why Systematic Maintenance is Non-Negotiable

A vacuum furnace is a precision instrument. Its primary function is to create a pure, controlled environment free from oxygen and other contaminants that would otherwise compromise the metallurgical properties of a part during heat treatment.

Even minor deviations from this ideal environment, such as a small leak or internal contamination, can negate the entire purpose of using a vacuum furnace. This leads to oxidation, decarburization, and inconsistent results, directly impacting product quality and scrap rates.

Component-Specific Maintenance Protocols

A robust maintenance plan is best organized by focusing on the key systems that work together to create the vacuum environment and execute the thermal cycle.

The Vacuum Chamber and Seals

The chamber is the sealed vessel where the entire process takes place. Its integrity is paramount. Maintenance involves inspecting the interior for any residue or spatter from previous cycles, which can vaporize and contaminate future loads.

Most importantly, the door seals and any other sealing surfaces must be regularly inspected for wear, cracks, or compression set. These seals are the primary barrier against atmospheric leaks and are a common point of failure.

The Heating Elements and Insulation

Heating elements and the surrounding insulation are critical for achieving fast, uniform heating. Elements should be inspected for distortion, cracking, or signs of arcing. The insulation pack (often graphite or ceramic) should be checked for degradation or contamination.

Degraded elements or insulation lead to poor temperature uniformity across the workload, resulting in inconsistent material properties. They also reduce thermal efficiency, increasing cycle times and energy costs.

The Vacuum Pumping System

The pumping system is the heart of the furnace, responsible for creating and maintaining the vacuum. Maintenance procedures depend on the type of pumps used (e.g., oil-sealed rotary vane, dry pumps, diffusion pumps).

This typically includes checking pump performance, verifying oil levels and quality (for oil-sealed pumps), and ensuring all filters are clean. A struggling pump will extend cycle times and may fail to reach the required vacuum level for sensitive processes.

The Cooling and Quenching System

For processes that require rapid cooling, the quenching system is vital. This involves inspecting the heat exchanger for leaks or blockages and ensuring the inert gas backfill and circulation systems are functioning correctly.

Clogged gas nozzles can cause non-uniform cooling, leading to thermal stress, distortion, and failure to achieve the desired hardness or microstructure in the final part.

The Control and Sensor Systems

The furnace’s "senses" rely on thermocouples for temperature measurement and gauges for vacuum measurement. These instruments require periodic checks and calibration.

Inaccurate readings from a drifting thermocouple or vacuum gauge can cause an entire batch to be processed outside of its required parameters, leading to scrapped parts that may appear dimensionally correct but are metallurgically flawed.

Understanding the Primary Point of Failure: The Vacuum Itself

While mechanical failures can occur, the most common and costly issues stem from a loss of vacuum integrity or purity.

The Critical Risk of Small Leaks

Even a microscopic leak that is difficult to detect can continuously introduce oxygen and nitrogen into the chamber. At high temperatures, this leads to surface oxidation and discoloration, defeating a primary advantage of vacuum processing.

The Impact of Cross-Contamination

Residue left in the furnace from one process, such as excess flux from a brazing cycle, can vaporize during the next cycle. This vapor can then contaminate a completely different load of sensitive parts, rendering them unusable. Rigorous cleaning between dissimilar processes is crucial.

The True Cost of Deferred Maintenance

Deferring the replacement of a worn door seal to "save" a small amount of money is a classic pitfall. This perceived saving is insignificant compared to the cost of a single scrapped batch of high-value aerospace or medical components due to a compromised vacuum environment.

Aligning Maintenance with Your Operational Goals

Your maintenance strategy should be tailored to your most critical business drivers.

- If your primary focus is Maximum Uptime: Prioritize preventative replacement of known wear items like seals, thermocouples, and pump filters on a fixed, data-driven schedule.

- If your primary focus is Uncompromising Part Quality: Implement rigorous chamber cleaning protocols between dissimilar processes and a strict, regular calibration schedule for all control sensors.

- If your primary focus is Cost Control: Routinely perform leak-down tests to identify vacuum integrity issues early and monitor energy consumption to spot inefficiencies caused by failing heating or insulation components.

Ultimately, disciplined maintenance transforms your vacuum furnace from a piece of equipment into a reliable, precision manufacturing asset.

Summary Table:

| Component | Key Maintenance Tasks | Common Issues Prevented |

|---|---|---|

| Vacuum Chamber & Seals | Inspect for residue, check seals for wear | Leaks, contamination, oxidation |

| Heating Elements & Insulation | Check for distortion, inspect insulation | Poor temperature uniformity, energy inefficiency |

| Vacuum Pumping System | Verify oil levels, clean filters | Extended cycle times, vacuum level failures |

| Cooling & Quenching System | Inspect heat exchangers, check gas nozzles | Non-uniform cooling, part distortion |

| Control & Sensor Systems | Calibrate thermocouples and gauges | Inaccurate processing, scrapped parts |

Ensure your vacuum furnace operates at peak efficiency with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace expertise, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs, enhancing uptime, part quality, and cost control. Don't let maintenance issues compromise your results—contact us today to discuss how we can support your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance