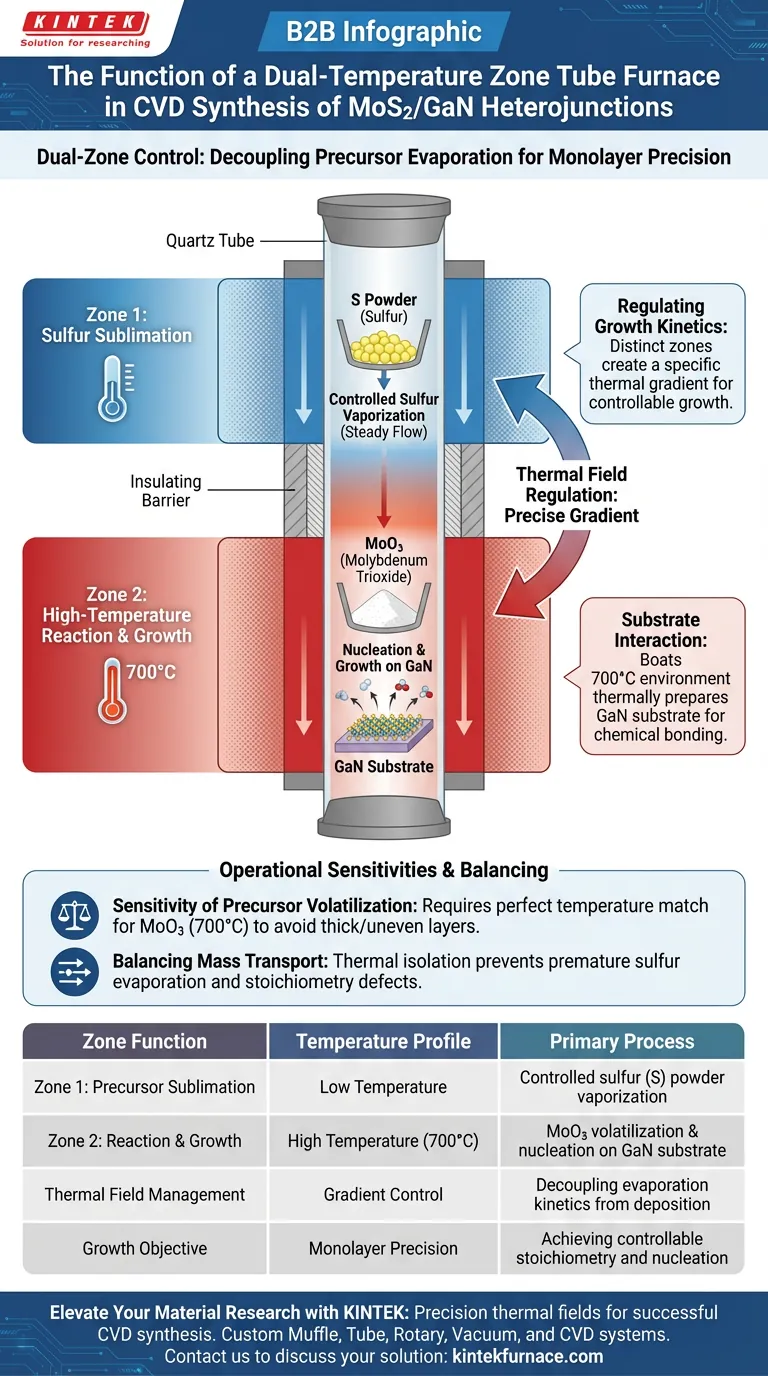

A dual-temperature zone tube furnace functions as the primary control environment for the Chemical Vapor Deposition (CVD) synthesis of MoS2/GaN heterojunctions. It provides two independently regulated heating zones that decouple the evaporation of the sulfur precursor from the high-temperature reaction required for molybdenum trioxide (MoO3) volatilization and subsequent growth on the Gallium Nitride (GaN) substrate.

Core Takeaway The success of growing monolayer MoS2 relies entirely on precise thermal field regulation. By isolating the low-temperature sublimation of sulfur from the high-temperature (700 °C) reaction zone, the furnace ensures that both precursors arrive at the substrate with the correct kinetics to achieve controllable nucleation and growth.

The Mechanism of Independent Zone Control

The fundamental challenge in CVD synthesis of heterojunctions is that different precursors evaporate at vastly different temperatures. A single-zone furnace cannot accommodate these conflicting requirements.

Zone 1: Sulfur Sublimation

The first heating zone is dedicated to the low-temperature sublimation of sulfur (S) powder.

Because sulfur has a relatively low boiling point, this zone operates at a lower temperature setting.

This independent control prevents the sulfur from vaporizing too quickly, ensuring a steady, controlled supply of vapor flows downstream toward the substrate.

Zone 2: High-Temperature Reaction

The second heating zone is the site of the primary chemical reaction and deposition.

This zone is maintained at a high temperature of 700 °C.

At this temperature, two critical processes occur simultaneously: the volatilization of the molybdenum trioxide (MoO3) precursor and the activation of the Gallium Nitride (GaN) substrate to support nucleation.

Regulating Growth Kinetics

Beyond simply heating materials, the furnace functions as a regulator of growth kinetics.

Thermal Field Regulation

The distinct separation between zones creates a specific thermal gradient.

This gradient allows the user to manipulate how fast precursors travel and react.

Proper regulation here is the defining factor in achieving controllable growth, specifically when targeting high-quality monolayer MoS2 structures.

Substrate Interaction

The GaN substrate resides in the high-temperature zone (Zone 2).

The 700 °C environment ensures the substrate is thermally prepared to accept the depositing atoms.

This facilitates the chemical bonding required to form the heterojunction between the MoS2 layer and the underlying GaN.

Understanding the Operational Sensitivities

While the dual-zone setup offers control, it also introduces complexity regarding process stability.

The Sensitivity of Precursor Volatilization

The system relies on the assumption that the temperature in Zone 2 (700 °C) perfectly matches the volatilization needs of MoO3 while simultaneously suiting the substrate.

If the temperature deviates, you risk incomplete volatilization (too cold) or uncontrolled, rapid deposition (too hot), resulting in thick or uneven layers rather than monolayers.

Balancing Mass Transport

The flow of sulfur from Zone 1 to Zone 2 is governed by the temperature difference and carrier gas flow.

If the thermal isolation between zones is poor (e.g., heat bleeding from Zone 2 to Zone 1), the sulfur may evaporate prematurely.

This disrupts the stoichiometry of the reaction, leading to defects in the final heterojunction.

Making the Right Choice for Your Experiment

To maximize the effectiveness of a dual-temperature zone furnace for MoS2/GaN synthesis, consider your specific experimental goals.

- If your primary focus is Monolayer Quality: Prioritize the stability of the second heating zone at 700 °C to ensure precise nucleation kinetics on the GaN substrate.

- If your primary focus is Stoichiometry (S:Mo Ratio): Focus on the fine-tuning of the first heating zone to regulate the sublimation rate of the sulfur powder, preventing sulfur deficiency.

Success in CVD synthesis is defined not just by reaching high temperatures, but by the independent control of those temperatures to orchestrate complex chemical reactions.

Summary Table:

| Zone Function | Temperature Profile | Primary Process |

|---|---|---|

| Zone 1: Precursor Sublimation | Low Temperature | Controlled sulfur (S) powder vaporization |

| Zone 2: Reaction & Growth | High Temperature (700°C) | MoO3 volatilization & nucleation on GaN substrate |

| Thermal Field Management | Gradient Control | Decoupling evaporation kinetics from deposition |

| Growth Objective | Monolayer Precision | Achieving controllable stoichiometry and nucleation |

Elevate Your Material Research with KINTEK

Precision thermal fields are the cornerstone of successful CVD synthesis. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory needs. Whether you are growing 2D heterojunctions or exploring advanced semiconductors, our dual-zone furnaces provide the independent temperature control necessary for superior stoichiometry and monolayer quality.

Ready to optimize your synthesis results? Contact our technical experts today to discuss your custom furnace solution!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance

- How does the sealing mechanism in Quartz Tube Furnaces differ from traditional systems? Discover Advanced Sealing for Reliable Results

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab