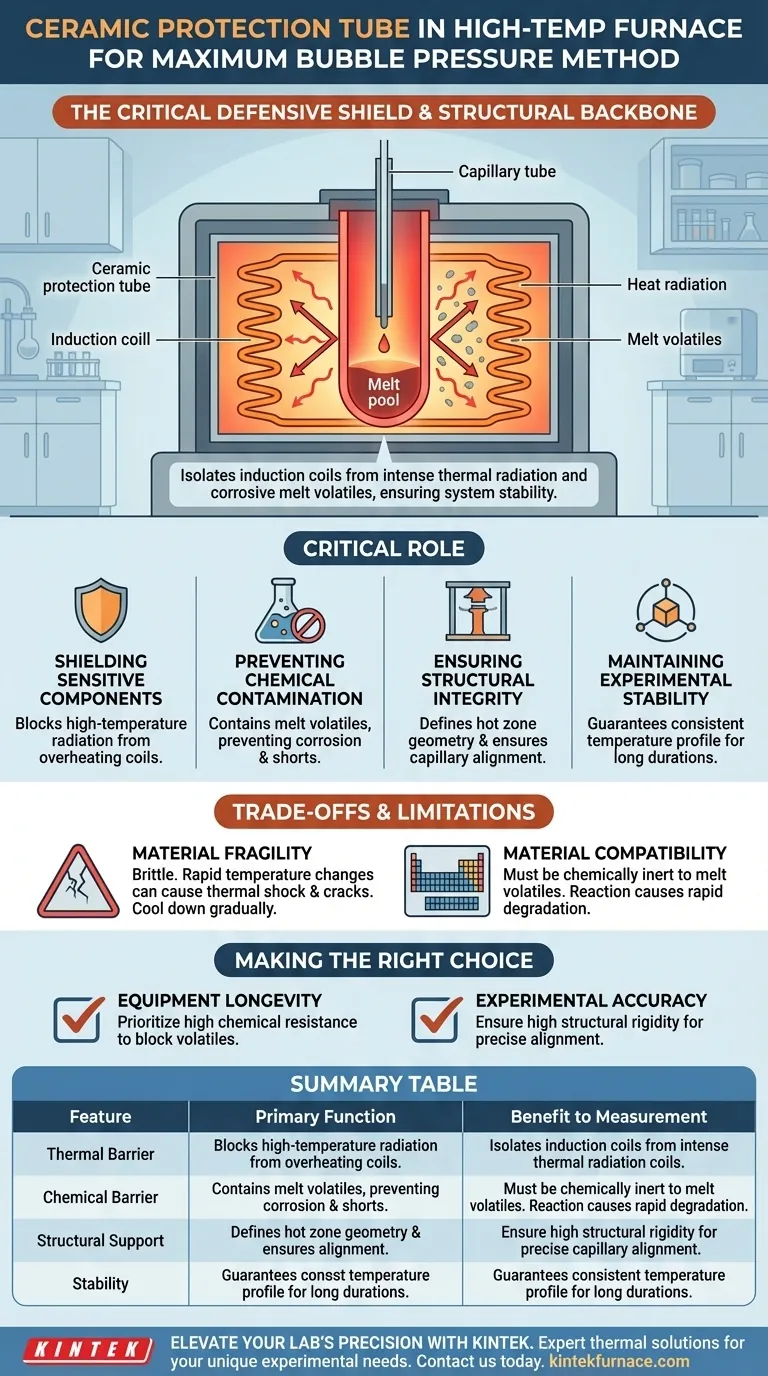

A ceramic protection tube serves as the critical defensive shield and structural backbone within your high-temperature furnace. Its primary function is to isolate sensitive induction coils from intense thermal radiation and corrosive melt volatiles. By acting as a physical barrier, it prevents component degradation and ensures the measurement system remains stable throughout the experiment.

The ceramic protection tube is not merely a structural component; it is a vital isolation barrier that protects induction coils from radiation and chemical attack, ensuring the long-term stability required for accurate maximum bubble pressure measurements.

The Critical Role of Protection in High-Temperature Measurements

Shielding Sensitive Components

In a setup utilizing the maximum bubble pressure method, the furnace often employs induction coils to generate heat.

These coils are highly susceptible to damage from the environment inside the chamber.

The ceramic tube acts as a physical barrier, specifically blocking high-temperature radiation that could overheat or damage the coils.

Preventing Chemical Contamination

When heating samples to the melting point, the material often releases melt volatiles (vapors).

Without a barrier, these volatile substances can deposit on the induction coils, leading to short circuits or corrosion.

The ceramic tube contains these volatiles within the central chamber, preserving the integrity of the heating elements.

Ensuring Structural Integrity

Beyond protection, the tube provides essential structural support for the furnace chamber components.

It defines the geometry of the hot zone, ensuring that the sample and measurement capillary remain perfectly aligned.

This structural rigidity is vital for maintaining the precise geometry required to calculate surface tension accurately.

Maintaining Experimental Stability

High-temperature experiments often require prolonged exposure to extreme heat.

The protection tube ensures the system operates stably over these long durations.

By preventing the degradation of the heating elements, it guarantees that the temperature profile remains consistent throughout the data collection process.

Understanding the Trade-offs and Limitations

Material Fragility and Thermal Shock

While ceramic tubes offer excellent heat resistance, they are inherently brittle.

Rapid heating or cooling can cause thermal shock, leading to cracks that compromise the barrier.

As noted in standard operating procedures, it is critical to allow the furnace to cool down gradually to prevent catastrophic failure of the tube.

Material Compatibility

Not all ceramic materials are suitable for every melt.

You must select a tube material and size that is chemically inert regarding the specific vapors released by your sample.

If the ceramic reacts with the melt volatiles, the tube will degrade rapidly, potentially contaminating your sample and ruining the experiment.

Making the Right Choice for Your Goal

To ensure your maximum bubble pressure setup functions correctly, consider these specific priorities:

- If your primary focus is Equipment Longevity: Prioritize a tube with high chemical resistance to block melt volatiles from corroding your induction coils.

- If your primary focus is Experimental Accuracy: Ensure the tube offers high structural rigidity to maintain precise alignment between the capillary and the melt surface.

A well-chosen ceramic protection tube is the silent guardian of your data, transforming a volatile high-heat environment into a stable laboratory workspace.

Summary Table:

| Feature | Primary Function | Benefit to Measurement |

|---|---|---|

| Thermal Barrier | Blocks high-temperature radiation | Protects induction coils from overheating |

| Chemical Barrier | Isolates melt volatiles (vapors) | Prevents corrosion and electrical short circuits |

| Structural Support | Defines hot zone geometry | Ensures alignment of capillary and sample |

| Stability | Maintains constant temp profile | Guarantees long-term experimental reliability |

Elevate Your Lab's Precision with KINTEK

Don't let equipment degradation compromise your high-temperature research. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique experimental needs.

Whether you require superior chemical resistance or extreme thermal stability, our specialized high-temperature furnaces provide the protection your sensitive measurements demand.

Contact us today to discuss how our expert thermal solutions can safeguard your lab equipment and enhance your data accuracy.

Visual Guide

References

- Lukas Neubert, Olena Volkova. Effect of Oxygen on Thermophysical Properties of Molten High-Silicon Electrical Steels and Its Impact on Bubble Formation Behavior. DOI: 10.1007/s11663-025-03594-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the advantages of glass tubing for heating applications? Key Benefits for Lab Efficiency

- How does a laboratory blast drying oven facilitate the treatment of Au/ZnO/In2O3 precursor precipitates? Key Benefits

- What are the benefits of 150mm thick ceramic fiber blankets in furnaces? Boost Efficiency and Safety

- Why are support frames important for the alumina furnace tube? Prevent High-Temperature Deformation and Failure

- How does a Mass Flow Controller (MFC) influence CrAlSiN coatings? Precision Ar/N2 Control for Hardness

- What is the function of a high-purity porcelain crucible? Expert Guide to Chromium-Doped Borosilicate Glass Preparation

- What are the advantages of using a platinum crucible? Essential for High-Purity Alumino-Borosilicate Glass Synthesis

- Is there a need to add water when launching the circulating water multifunctional vacuum pump? Ensure Optimal Performance and Avoid Damage