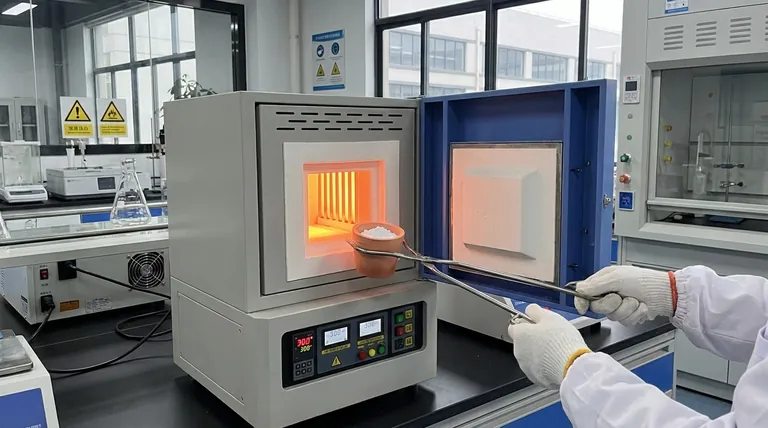

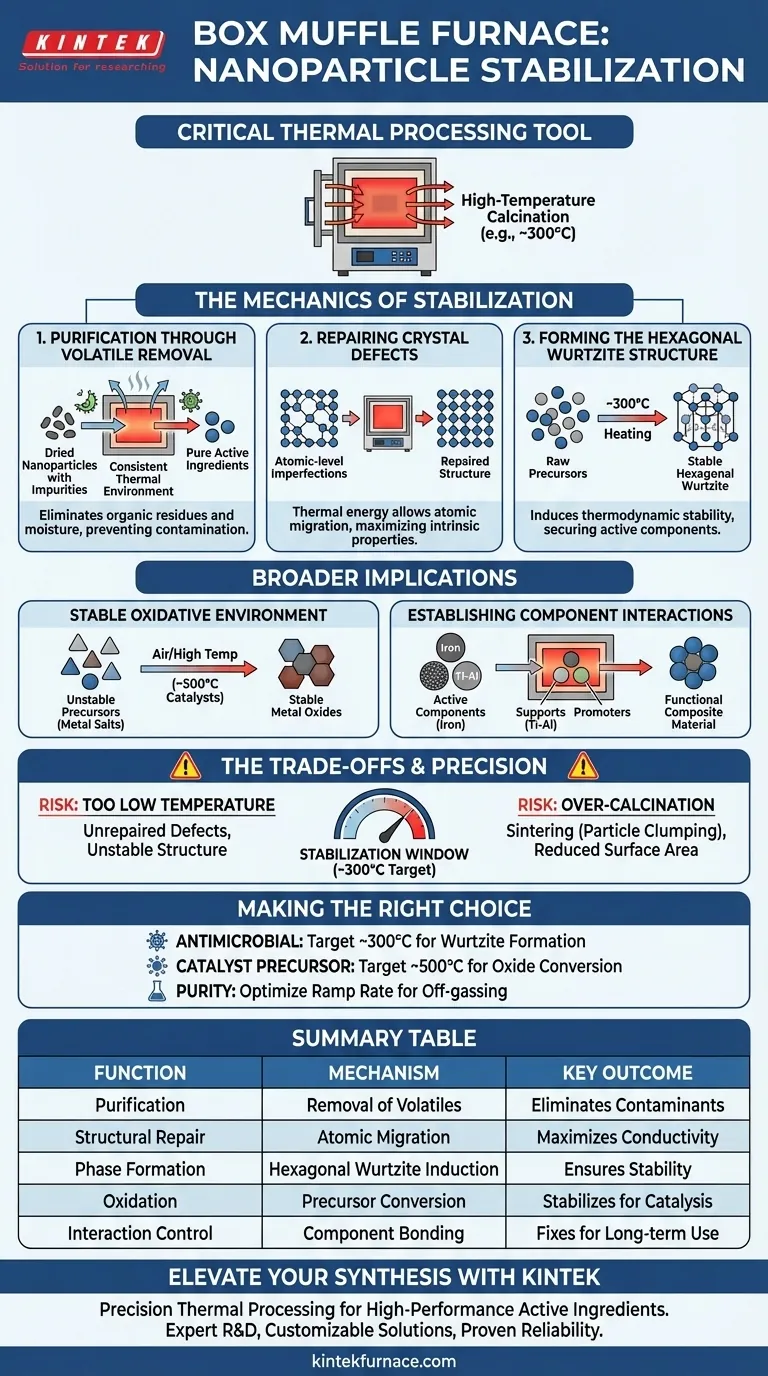

A box muffle furnace functions as a critical thermal processing tool used to stabilize nanoparticle active ingredients through high-temperature calcination. By subjecting dried nanoparticles to controlled heat—specifically around 300°C for many antimicrobial applications—the furnace eliminates volatile impurities and fundamentally rearranges the material's atomic structure to ensure long-term stability and efficacy.

The muffle furnace does more than just dry materials; it engineers their atomic structure. Through calcination, it eliminates organic residues and repairs crystal defects, transforming raw precursors into stable, highly active phases like the hexagonal wurtzite structure required for performance.

The Mechanics of Stabilization

Purification Through Volatile Removal

The initial function of the muffle furnace is the purification of the nanoparticle sample.

During the drying phase of synthesis, nanoparticles often retain organic volatiles and moisture. The furnace provides a consistent thermal environment that drives these residual organics out of the material.

By removing these impurities, the furnace ensures that the final product consists purely of the active ingredients, preventing contaminants from interfering with chemical performance.

Repairing Crystal Defects

Beyond purification, the furnace plays a vital role in correcting the internal structure of the nanoparticles.

Raw nanoparticles often contain atomic-level imperfections or "defects" in their crystal lattice. The thermal energy provided by the muffle furnace allows atoms to migrate and settle into more energetically favorable positions, effectively repairing these defects.

This structural repair is essential for maximizing the intrinsic properties of the material, such as conductivity or reactivity.

Forming the Hexagonal Wurtzite Structure

The most critical stabilization function is the induction of a specific phase transformation.

For certain antimicrobial nanoparticles, heating at 300°C facilitates the formation of a stable hexagonal wurtzite structure. This specific crystalline arrangement is thermodynamically stable and is directly responsible for "securing" the active components.

Without this phase transformation, the nanoparticles would lack the structural integrity required to maintain their active properties over time.

Broader Implications for Active Ingredients

Creating a Stable Oxidative Environment

While specific temperatures vary by material, the muffle furnace generally provides a stable, high-temperature oxidative environment (often in air).

This environment is crucial for converting unstable precursors, such as metal salts, into stable metal oxide phases. For example, in catalyst preparation, temperatures around 500°C allow for the complete dehydration and decomposition of precursors.

Establishing Component Interactions

The furnace ensures the development of ideal interactions between various elements in a composite material.

Precise temperature control allows active components (like Iron) to bond effectively with supports (like Titanium-Aluminum) and promoters. This thermal treatment establishes the necessary structural foundation, ensuring the active ingredients remain fixed and functional during use.

Understanding the Trade-offs

The Necessity of Precision

The primary challenge in using a muffle furnace is the requirement for high-precision temperature control.

If the temperature is too low, the crystal defects will not be repaired, and the hexagonal wurtzite structure may not fully form. This results in an unstable, inefficient product.

Risks of Over-Calcination

Conversely, excessive heat can lead to sintering, where nanoparticles merge into larger clumps.

This reduces the surface area and diminishes the effectiveness of the active ingredients. The "stabilization" window is specific; for the antimicrobial particles mentioned, 300°C is the target to balance defect repair with particle integrity.

Making the Right Choice for Your Goal

To maximize the efficacy of your nanoparticle synthesis, align your thermal treatment with your specific material requirements:

- If your primary focus is Antimicrobial Efficacy: Target a calcination temperature of 300°C to ensure the formation of the hexagonal wurtzite structure and the repair of crystal defects.

- If your primary focus is Catalyst Precursor Conversion: Higher temperatures (around 500°C) may be necessary to fully dehydrate metal salts and convert them into stable metal oxides.

- If your primary focus is Purity: Ensure the furnace ramp rate allows sufficient time for organic volatiles to off-gas completely before the lattice structure locks into place.

The muffle furnace is not merely a heater, but a precision instrument that dictates the final structural identity and performance of your active ingredients.

Summary Table:

| Function | Mechanism | Key Outcome |

|---|---|---|

| Purification | Removal of organic volatiles & moisture | Eliminates contaminants and interference |

| Structural Repair | Atomic migration to fix lattice defects | Maximizes conductivity and reactivity |

| Phase Formation | Induction of hexagonal wurtzite structure | Ensures thermodynamic stability & integrity |

| Oxidation | Conversion of metal salts to metal oxides | Stabilizes precursors for catalytic use |

| Interaction Control | Bonding active components with supports | Fixes ingredients for long-term functionality |

Elevate Your Nanoparticle Synthesis with KINTEK

Precision thermal processing is the difference between unstable precursors and high-performance active ingredients. KINTEK provides industry-leading muffle, tube, and vacuum furnace systems designed to deliver the exact temperature control required for crystal defect repair and phase transformation.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems are engineered for uniform heating and high-precision stability.

- Customizable Solutions: Whether you need 300°C for antimicrobial stabilization or 500°C+ for catalyst conversion, we tailor our high-temp furnaces to your unique lab needs.

- Proven Reliability: Trusted by researchers globally for sensitive material engineering.

Don't let over-calcination or structural defects compromise your research. Contact KINTEK today to find your perfect thermal solution!

Visual Guide

References

- Miss Mahjabina, Zainul Abideen. Production and characterization of chitosan nanoparticles extracted from Pinus roxburghii needles enhances disease protection against citrus canker. DOI: 10.21203/rs.3.rs-7226794/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the environmental requirements for muffle furnace operation? Ensure Safety and Precision in Your Lab

- What role does a muffle furnace play in the post-treatment process of Ruthenium-Chromium oxide aerogels? Key Insights

- What are the safety precautions when using a box type electric furnace? Ensure Operator and Equipment Protection

- What maintenance considerations are important for muffle furnaces? Ensure Accuracy, Safety, and Longevity

- Why Use a Programmable Muffle Furnace for Perovskite Calcination? Achieve 1100°C Phase Purity

- What are the advantages of using a Microwave Muffle Furnace? Faster, Higher-Quality Activated Carbon Preparation

- How are muffle furnaces utilized in dental laboratories? Essential for Sintering, Firing, and Casting

- What are the general characteristics and advantages of box type resistance furnaces? Discover Versatile Heating Solutions for Your Lab