Proper maintenance of a muffle furnace is essential for ensuring its accuracy, safety, and longevity. The core considerations involve regularly inspecting the heating elements for wear, cleaning the chamber to prevent residue buildup and contamination, verifying the temperature controller's calibration for process accuracy, and checking the integrity of the insulation and door seals to maintain thermal efficiency.

Muffle furnace maintenance is not merely about preventing failure; it is about preserving the core functions of precision and repeatability. Neglecting these tasks compromises experimental or production results, introduces safety hazards, and shortens the lifespan of a critical piece of equipment.

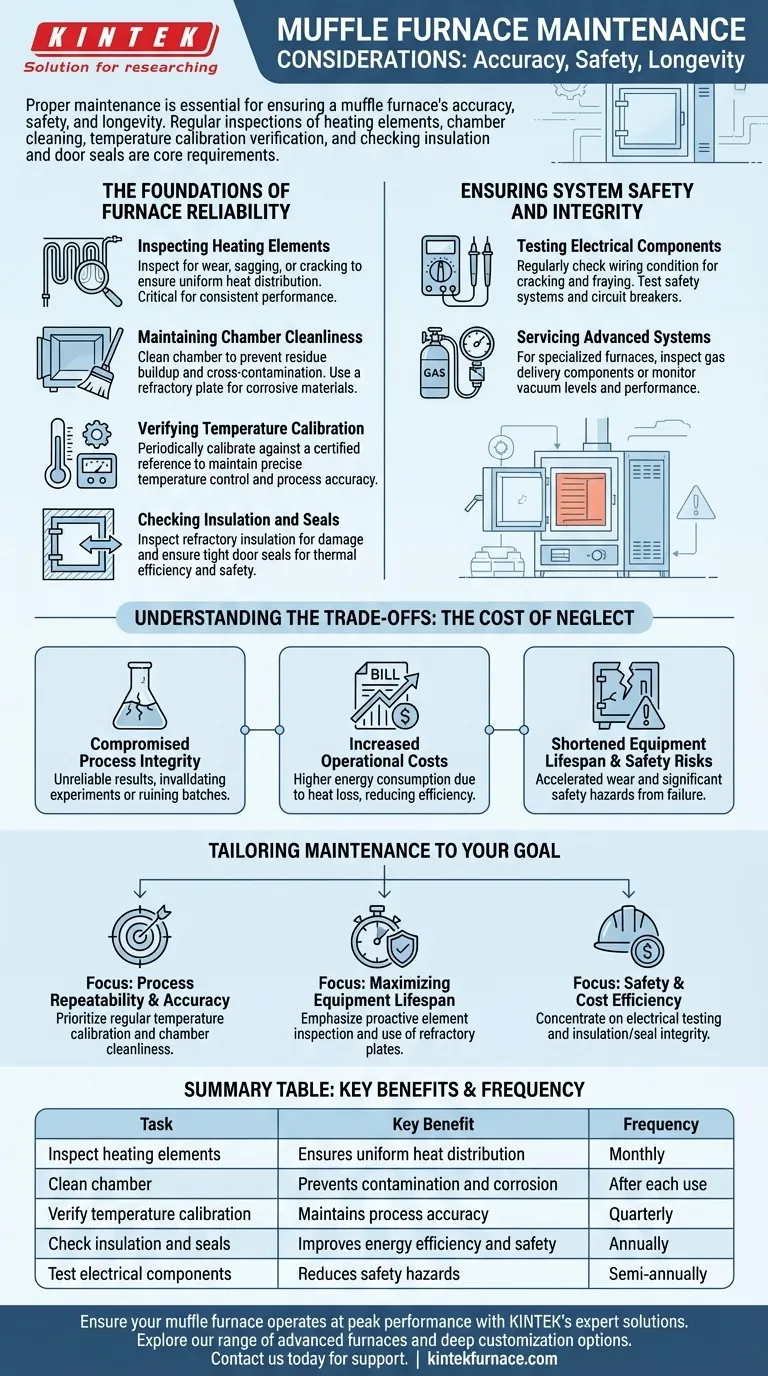

The Foundations of Furnace Reliability

A systematic maintenance approach addresses the key components responsible for the furnace's performance. Each area directly impacts the quality of your work.

Inspecting Heating Elements

Heating elements are the heart of the furnace. Over time, they degrade from thermal cycling, which can lead to uneven heating or complete failure.

Regular visual inspection for signs of sagging, cracking, or discoloration is critical. This ensures the furnace continues to provide the uniform heat distribution it was designed for.

Maintaining Chamber Cleanliness

The furnace chamber is designed to provide a clean, controlled environment. Residue, oxides, or spillage from samples can compromise this.

Cleaning out debris prevents cross-contamination between batches and protects the chamber's interior surfaces from chemical attack.

For processes involving materials that may corrode the furnace lining, placing a refractory plate or hearth plate at the bottom of the chamber is a crucial preventative measure.

Verifying Temperature Calibration

A muffle furnace's primary value is its precise temperature control. However, the accuracy of thermocouples and controllers can drift over time.

Periodic calibration against a certified reference is the only way to ensure the setpoint temperature matches the actual chamber temperature. Without this, your process parameters are unreliable.

Checking Insulation and Seals

The furnace's efficiency and temperature stability depend on its insulation. Cracks or degradation in the insulation lead to heat loss.

Inspect the refractory insulation for visible damage. Equally important, check the door seal for a tight fit to prevent heat leakage and protect operators.

Ensuring System Safety and Integrity

Beyond core performance, maintenance is your first line of defense against equipment failure and safety incidents.

Testing Electrical Components

Faulty electrical systems are a significant safety hazard. Wires can become brittle from exposure to high temperatures over time.

Regularly check the condition of all wiring for signs of cracking or fraying. Additionally, test safety systems like circuit breakers to ensure they function correctly.

Servicing Advanced Systems (If Equipped)

Many modern furnaces have specialized systems that require their own maintenance schedules.

If your furnace uses a protective atmosphere, inspect the gas delivery components for leaks or wear. For vacuum models, monitor the system's performance to ensure it can reach and hold the required vacuum level.

Understanding the Trade-offs: The Cost of Neglect

Skipping or delaying maintenance may seem to save time, but it carries significant hidden costs and risks that far outweigh the effort.

Compromised Process Integrity

The most immediate impact of poor maintenance is unreliable results. An uncalibrated furnace or one with failing elements cannot produce consistent, repeatable outcomes, invalidating experiments or ruining production batches.

Increased Operational Costs

Degraded insulation or poor door seals force the furnace to consume more energy to maintain its setpoint. This directly increases electricity bills and reduces the energy efficiency of your operation.

Shortened Equipment Lifespan

Allowing corrosive residue to build up or running the furnace with failing elements puts immense stress on all its components. This neglect accelerates wear and tear, leading to premature and costly failure of the entire unit.

Significant Safety Risks

Failing to inspect electrical components or safety interlocks exposes operators to the risk of electrical shock or other serious accidents. A well-maintained furnace is a safe furnace.

Tailoring Maintenance to Your Goal

Your maintenance strategy should align with your primary operational objective. A consistent schedule is key, but your focus may shift depending on your priorities.

- If your primary focus is process repeatability and accuracy: Prioritize regular temperature calibration and chamber cleanliness to guarantee consistent and uncontaminated results.

- If your primary focus is maximizing equipment lifespan: Emphasize proactive inspection of heating elements and the use of refractory plates to protect against corrosion and wear.

- If your primary focus is safety and cost efficiency: Concentrate on testing electrical components and ensuring the integrity of the insulation and door seals.

Ultimately, viewing maintenance as a strategic practice rather than a chore transforms it into a powerful tool for ensuring operational excellence.

Summary Table:

| Maintenance Task | Key Benefit | Frequency |

|---|---|---|

| Inspect heating elements | Ensures uniform heat distribution | Monthly |

| Clean chamber | Prevents contamination and corrosion | After each use |

| Verify temperature calibration | Maintains process accuracy | Quarterly |

| Check insulation and seals | Improves energy efficiency and safety | Annually |

| Test electrical components | Reduces safety hazards | Semi-annually |

Ensure your muffle furnace operates at peak performance with KINTEK's expert solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace options, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing accuracy, safety, and longevity. Contact us today to discuss how we can support your maintenance goals and optimize your lab's efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites