At a fundamental level, Silicon Carbide (SiC) is a versatile and robust heating element suited for a wide range of high-temperature processes, especially those requiring rapid heating. In contrast, Molybdenum Disilicide (MoSi2) is a specialized material designed for extreme temperature applications, offering superior performance above 1500°C at the cost of requiring more stringent operating conditions.

The choice between SiC and MoSi2 is not about which is superior overall, but which is the correct tool for your specific application. The decision hinges on a critical trade-off between the maximum temperature you need to achieve and the level of operational maintenance you can commit to.

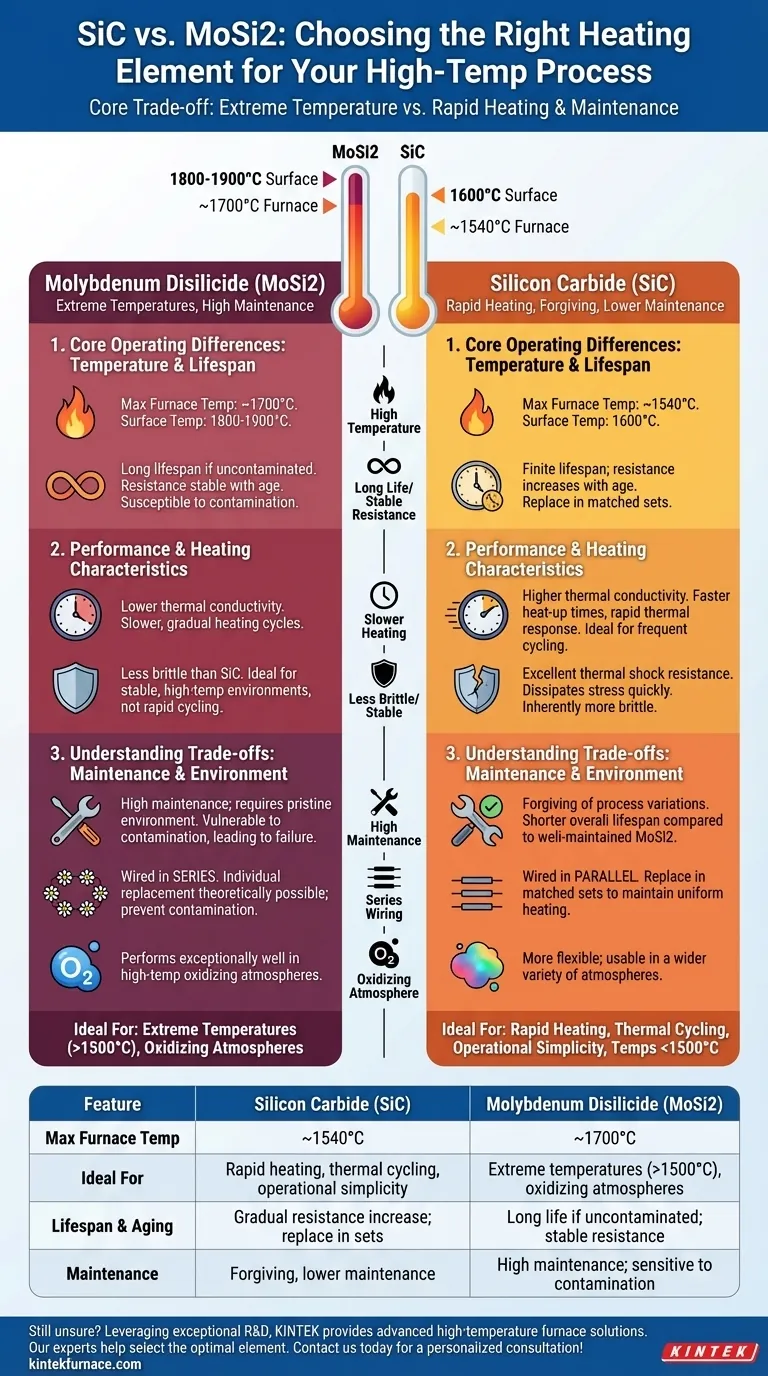

Core Operating Differences: Temperature and Lifespan

The primary factors that distinguish these two materials are their temperature limits and how they degrade over time.

Maximum Operating Temperature

Molybdenum Disilicide (MoSi2) is the clear choice for the highest temperature ranges. Its elements can reach surface temperatures of 1800-1900°C, enabling furnace operating temperatures up to approximately 1700°C.

Silicon Carbide (SiC) elements have a lower maximum surface temperature of around 1600°C. This translates to a practical maximum furnace operating temperature of about 1540°C.

Element Lifespan and Aging

SiC elements have a finite lifespan characterized by a gradual increase in electrical resistance as they age. This change requires adjustments to the power supply and means that when one element fails, the entire set (or at least a matched pair) must be replaced to maintain uniform heating.

MoSi2 elements can have a very long service life, especially when operated consistently above 1500°C. Unlike SiC, their resistance does not significantly change with age, but they are highly susceptible to damage from contamination.

Performance and Heating Characteristics

How an element transfers heat and responds to temperature changes directly impacts your process efficiency and outcomes.

Heating Rate and Thermal Conductivity

SiC possesses a higher thermal conductivity. This allows for more efficient heat transfer, resulting in faster furnace heat-up times and a more rapid thermal response, which is ideal for processes involving frequent cycling.

MoSi2 has a lower thermal conductivity. This makes it better suited for applications that benefit from slower, more gradual heating cycles.

Thermal Shock vs. Brittleness

SiC is known for its excellent thermal shock resistance, meaning it can withstand rapid changes in temperature without failing. This is largely due to its high thermal conductivity, which dissipates thermal stress quickly. However, it is inherently a more brittle material.

MoSi2 is a less brittle material than SiC. While robust, its primary application is in stable, high-temperature environments rather than processes defined by rapid thermal cycling.

Understanding the Trade-offs: Maintenance and Environment

Operational requirements are just as critical as material properties. The environment inside your furnace and your maintenance protocol will heavily influence which element is the right choice.

The Maintenance Burden

MoSi2 elements demand a high level of care. They are vulnerable to contamination, and improper furnace maintenance can lead to premature failure. These are high-performance elements that require a pristine operating environment.

SiC elements are significantly more forgiving of process variations and less-than-perfect furnace conditions. This operational robustness often comes at the price of a shorter overall lifespan compared to a well-maintained MoSi2 system.

Wiring and Replacement Strategy

Furnaces with SiC elements are typically wired in parallel. Because the elements age and their resistance changes, they must be replaced in matched sets to ensure the furnace continues to heat evenly.

Furnaces using MoSi2 elements are wired in series. While individual elements can theoretically be replaced, the primary concern remains preventing the contamination that causes failure in the first place.

Atmospheric Conditions

MoSi2 performs exceptionally well in high-temperature oxidizing atmospheres, which is its most common application.

SiC is more flexible and can be used effectively in a wider variety of atmospheres, making it a more versatile choice for labs or shops that run diverse processes.

Making the Right Choice for Your Goal

Select your heating element based on your primary process requirement, not just on a single material specification.

- If your primary focus is extreme temperature (above 1540°C): Choose MoSi2, but be prepared to invest in rigorous furnace maintenance and process control to protect the elements from contamination.

- If your primary focus is rapid heating and thermal cycling: Choose SiC for its superior thermal conductivity and proven resistance to thermal shock.

- If your primary focus is operational simplicity and temperatures below 1500°C: Choose SiC for its forgiving nature and lower maintenance requirements, while accepting the need for periodic replacement.

Ultimately, an informed decision requires aligning the element's distinct strengths and weaknesses with the specific demands of your thermal process.

Summary Table:

| Feature | Silicon Carbide (SiC) | Molybdenum Disilicide (MoSi2) |

|---|---|---|

| Max Furnace Temp | ~1540°C | ~1700°C |

| Ideal For | Rapid heating, thermal cycling, operational simplicity | Extreme temperatures (>1500°C), oxidizing atmospheres |

| Lifespan & Aging | Gradual resistance increase; replace in sets | Long life if uncontaminated; stable resistance |

| Maintenance | Forgiving, lower maintenance | High maintenance; sensitive to contamination |

Still unsure which heating element is right for your process?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let our experts help you select the optimal heating element for your specific temperature, cycling, and maintenance needs. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C