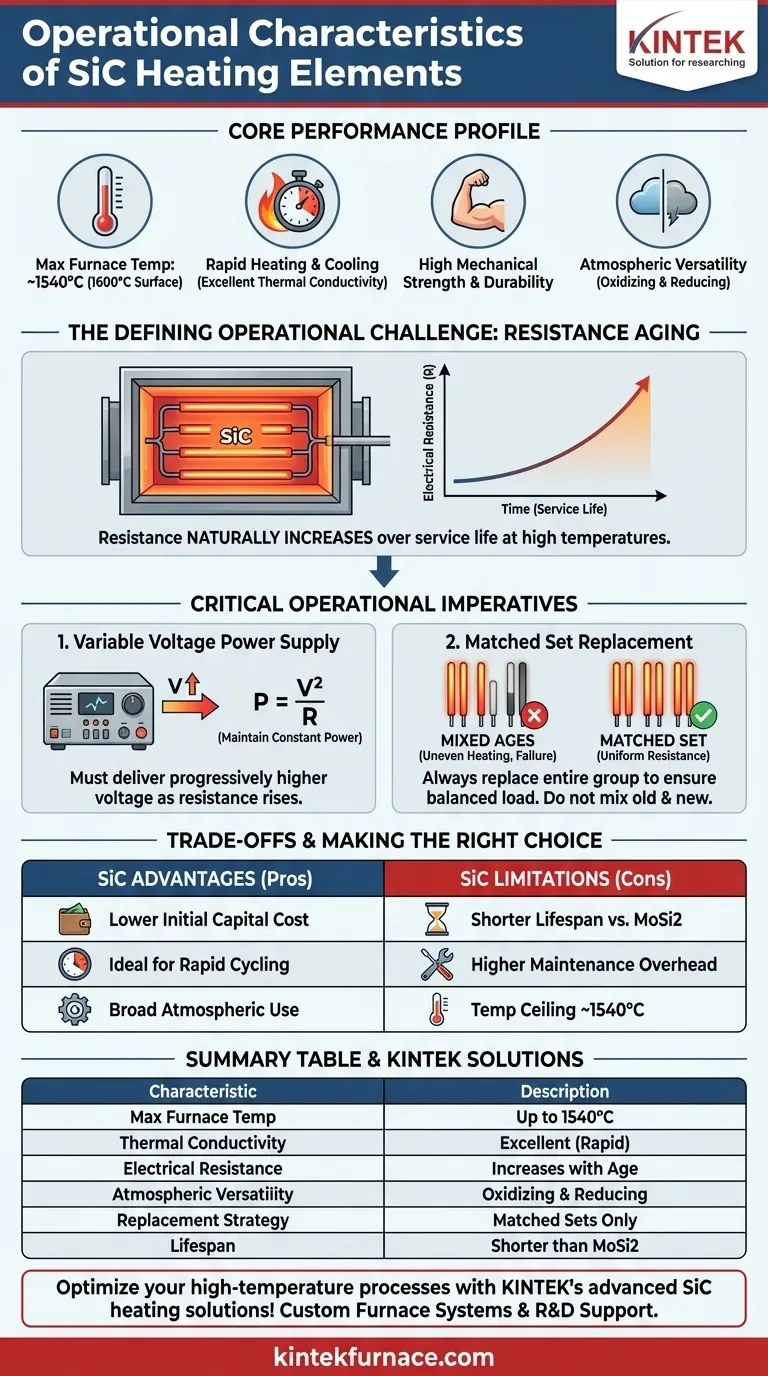

In short, Silicon Carbide (SiC) heating elements are defined by their ability to operate up to furnace temperatures of 1540°C, their excellent thermal conductivity for rapid heating, and their high mechanical strength. Operationally, their electrical resistance increases as they age, which necessitates the use of a variable voltage power supply and requires that they be replaced in matched sets rather than individually.

Silicon carbide elements are versatile, high-temperature workhorses valued for speed and strength. However, their defining operational characteristic is a gradual increase in resistance over time, which dictates their power supply requirements, maintenance strategy, and ultimate lifespan.

The Core Performance Profile of SiC Elements

SiC elements are a foundational technology in high-temperature industrial processes. Their specific material properties translate directly into key performance benefits.

High-Temperature Capability

SiC elements can achieve a surface temperature of approximately 1600°C. This allows for a maximum sustainable furnace chamber temperature between 1530°C and 1540°C, placing them firmly in the high-temperature heating category.

Superior Thermal Management

These elements possess excellent thermal conductivity, enabling rapid heating and cooling speeds. This ensures quick and even heat distribution throughout a furnace, which is critical for process control, energy efficiency, and reducing the risk of localized overheating.

Mechanical Strength and Durability

Even at extreme temperatures, SiC maintains high mechanical strength. It is also highly resistant to thermal shock and chemical corrosion, making it a robust choice for demanding industrial environments.

Atmospheric Versatility

A key advantage of SiC is its ability to perform well in both oxidizing and reducing atmospheres. This makes it more versatile than alternatives like Molybdenum Disilicide (MoSi2), which can be damaged in certain reducing environments.

Critical Operational Considerations

Operating a furnace with SiC elements requires understanding their unique aging process and the maintenance practices that arise from it. These are not "set-it-and-forget-it" components.

The Challenge of Aging and Resistance

The most critical operational characteristic of a SiC element is that its electrical resistance increases over its service life. This aging process is a natural and unavoidable consequence of its use at high temperatures.

Power Supply Requirements

Because resistance increases with age, the power supply must be able to compensate to maintain constant power output and temperature (Power = Voltage² / Resistance). Therefore, systems using SiC elements require a transformer or power controller capable of delivering progressively higher voltage over the element's lifespan.

Parallel Wiring and Replacement Strategy

SiC elements are wired in parallel circuits. If elements with different resistance values (i.e., a new element and an old one) are on the same circuit, they will draw different amounts of power, leading to uneven heating and premature failure. For this reason, when one element fails, you must replace the entire group or set to ensure all elements have a matched resistance.

Lifespan Relative to Alternatives

While robust, SiC heating elements generally have a shorter operational lifespan compared to MoSi2 elements. The rate of resistance increase and eventual end-of-life depends heavily on operating temperature, atmosphere, and power cycling frequency.

Understanding the Trade-offs

Choosing SiC elements involves balancing their distinct advantages against their specific operational demands and limitations.

The Cost vs. Lifespan Balance

SiC elements are often selected for applications where initial capital cost is a primary concern. They provide excellent high-temperature performance for their price point, but this comes at the expense of a shorter lifespan and higher maintenance overhead compared to premium alternatives like MoSi2.

The Temperature Ceiling

While capable of very high heat, the ~1540°C furnace temperature is a practical limit. For processes requiring temperatures above this threshold, other element types become necessary.

The Maintenance Overhead

The need to monitor resistance, manage a variable power supply, and replace elements in matched sets constitutes a significant operational commitment. This maintenance is essential for reliable and consistent furnace performance.

Making the Right Choice for Your Application

Your ideal heating element depends entirely on your process priorities.

- If your primary focus is rapid cycling and atmospheric versatility: SiC is an excellent choice for batch processing in electronics or ceramics where you need fast heat-up and cool-down times.

- If your primary focus is maximizing temperature and minimizing maintenance: You should strongly consider MoSi2 elements, as they offer longer lifespans and can reach higher furnace temperatures with less intensive management.

- If your primary focus is controlling initial cost for mid-range high-temperature work: SiC provides a powerful balance of performance and affordability for applications that do not exceed the 1540°C threshold.

Understanding these operational characteristics is the key to leveraging the power of SiC elements while effectively managing their lifecycle.

Summary Table:

| Characteristic | Description |

|---|---|

| Max Furnace Temperature | Up to 1540°C |

| Thermal Conductivity | Excellent for rapid heating and cooling |

| Electrical Resistance | Increases with age, requires variable voltage supply |

| Atmospheric Versatility | Works in oxidizing and reducing atmospheres |

| Replacement Strategy | Must be replaced in matched sets |

| Lifespan | Shorter than MoSi2, depends on temperature and usage |

Optimize your high-temperature processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how our expertise can benefit your application!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions