Based on user reports, customer feedback for the dental zirconia sintering furnace's support services is consistently positive. Users describe the customer service team as both responsive and helpful when questions or operational issues arise. This positive support experience is part of a broader pattern of user satisfaction, which also includes praise for the furnace's reliability and intuitive design.

The key takeaway is not just that the support is good, but that the furnace's inherent reliability and user-friendly interface reduce the overall need for support. This combination is the strongest indicator of a low-friction ownership experience for a dental lab.

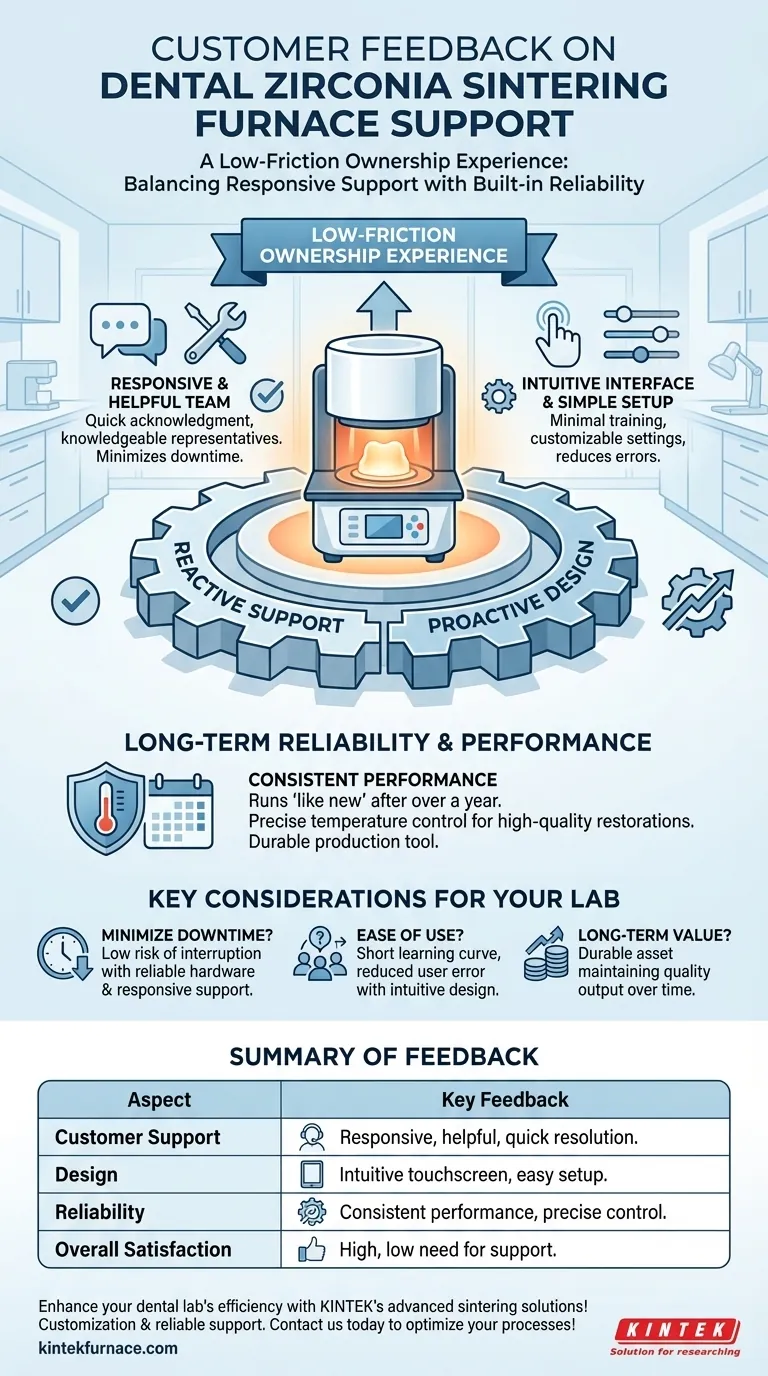

The Pillars of a Positive Ownership Experience

When evaluating a significant piece of lab equipment like a sintering furnace, the quality of customer support is a critical factor. However, user feedback suggests that the best support experience is one you rarely need. The overall positive sentiment is built on two key areas: proactive design and reactive support.

Direct Feedback on Customer Support

Users who have needed to contact the support team report positive outcomes. The service is characterized as responsive, implying quick acknowledgment of issues, and helpful, suggesting that representatives are knowledgeable and capable of resolving problems effectively.

This provides confidence that if an unexpected issue occurs, the manufacturer has a reliable system in place to assist the user and minimize downtime.

The Role of Intuitive Design

A significant factor reducing the need for support is the furnace's design. Users specifically praise the intuitive touchscreen interface and the simplicity of setting up sintering cycles.

This ease of use requires minimal training for lab technicians. Furthermore, the ability to create customizable settings for different zirconia materials streamlines workflow and reduces the chance of user error, a common reason for support calls with more complex equipment.

Long-Term Reliability and Performance

The most crucial element contributing to user satisfaction is the furnace's reported reliability. Feedback indicates the machine delivers reliable performance over time, with one user noting their unit runs "like new" after more than a year of consistent use.

This long-term consistency in maintaining precise sintering temperatures is vital for producing high-quality, predictable restorations. It shows the equipment is not just easy to use, but also a durable and dependable production tool.

Understanding the Complete Picture

While the available feedback is overwhelmingly positive, a thorough evaluation requires considering the context and potential unstated factors. As a technical advisor, it is my responsibility to ensure you have a balanced perspective.

The Context of Feedback

It is important to recognize that available reports, while positive, may represent a specific segment of the user base. Always consider the scale and source of feedback when making a final purchasing decision.

Defining "Responsive" Support

The term "responsive" can be subjective. For your specific lab's needs, it is wise to clarify the details of the service level agreement (SLA). Inquire about support hours, typical response times, and the channels available (phone, email, remote diagnostics).

The Importance of Maintenance

No piece of high-performance equipment is immune to the need for proper care. The reports of long-term reliability are almost certainly linked to users following the recommended maintenance schedules. A reliable machine still requires a responsible operator to ensure its longevity.

Key Considerations for Your Lab

Your final decision should be aligned with your lab's specific operational priorities. Use the following points to guide your evaluation.

- If your primary focus is minimizing downtime: The furnace's reported reliability, combined with responsive support, suggests a low risk of extended operational interruptions.

- If your primary focus is ease of use for your team: The intuitive interface and simple cycle setup indicate a short learning curve and reduced potential for user error.

- If your primary focus is long-term investment value: Reports of consistent, precise performance over time suggest the furnace is a durable asset that maintains its quality output.

Ultimately, the evidence points toward a well-supported product that is engineered to be reliable and easy to operate from the start.

Summary Table:

| Aspect | Key Feedback |

|---|---|

| Customer Support | Responsive and helpful service, quick issue resolution |

| Design | Intuitive touchscreen interface, easy setup, customizable settings |

| Reliability | Consistent performance over time, precise temperature control |

| Overall Satisfaction | High user satisfaction, low need for support due to reliability and ease of use |

Enhance your dental lab's efficiency with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, tailored to your unique needs. Benefit from our deep customization capabilities and reliable support to ensure precise, durable performance. Contact us today to discuss how we can optimize your sintering processes and boost productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision