The primary benefit of operating a rotary furnace as a batch furnace is the combination of superior process uniformity with precise, repeatable control over a specific quantity of material. This allows for customized heat treatment cycles and simplified material management, as the furnace charge can be easily calculated and tracked on a per-batch basis.

A rotary furnace's core strength is its ability to mix and heat materials evenly. Operating it in batch mode harnesses that strength and applies it to a discrete, measurable lot, giving you the precision of a laboratory-grade process with the capability of an industrial tool.

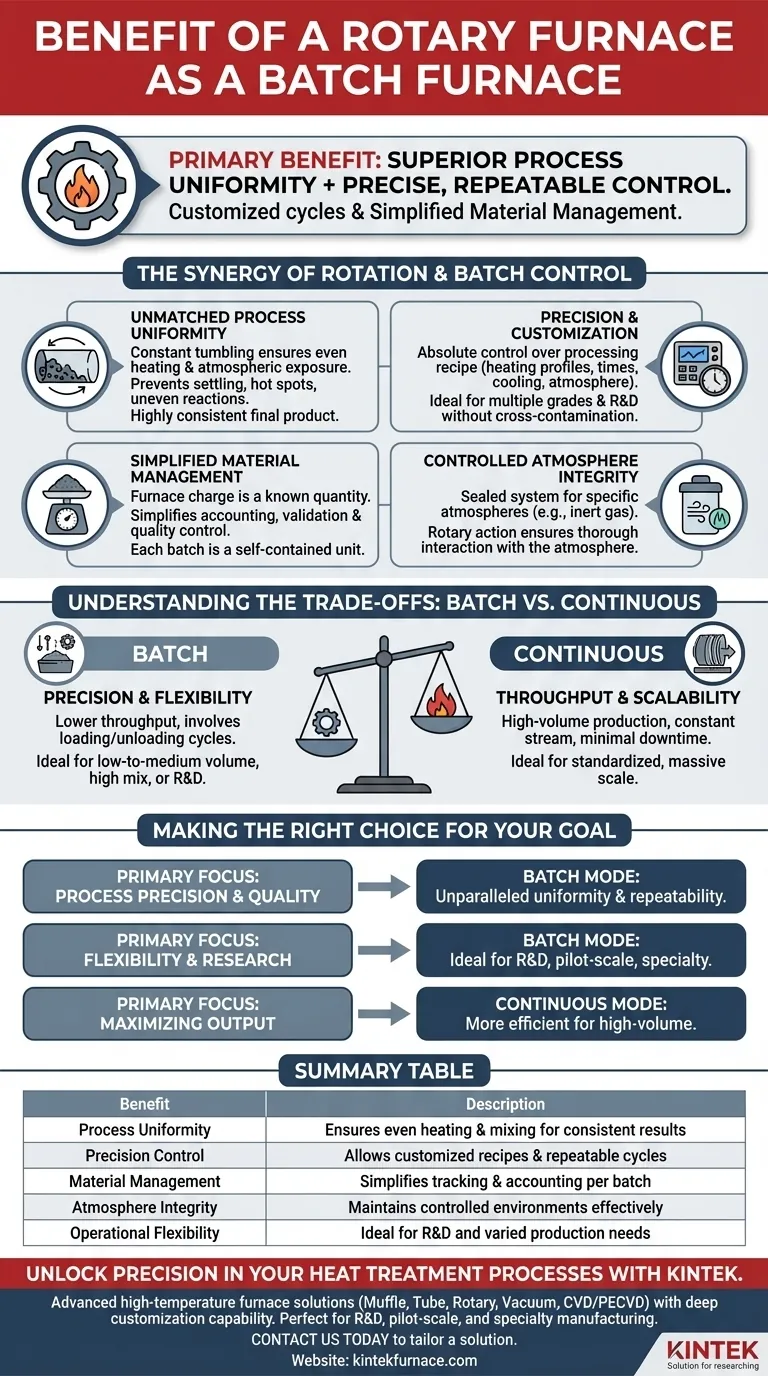

The Synergy of Rotation and Batch Control

The decision to use a rotary furnace in batch mode is not about compromise; it's about combining the distinct advantages of two different methodologies to achieve a specific, high-value outcome. This synergy addresses challenges that neither a static batch furnace nor a continuous rotary furnace can solve as effectively on their own.

Unmatched Process Uniformity

The defining feature of a rotary furnace is its rotating tube. This constant tumbling action ensures every particle within the batch is exposed to the same temperature and atmospheric conditions.

This prevents common issues like sample settling, hot spots, or uneven reactions, leading to a highly consistent and uniform final product. The mechanical mixing enhances heat transfer efficiency, often resulting in faster and more uniform processing.

Precision and Customization

Batch operation gives you absolute control over the processing recipe for a single, contained lot. You can program precise heating profiles, holding times, cooling rates, and atmospheric compositions tailored specifically for that material.

This is invaluable when working with multiple material grades or developing new processes, as you can run vastly different treatment cycles back-to-back without cross-contamination or lengthy recalibration.

Simplified Material Management

When operating in batch mode, the furnace charge is a known quantity, calculated by weight or volume before processing begins. This simplifies material accounting and process validation immensely.

For industries requiring strict quality control and traceability, treating material in discrete, documented batches is a critical advantage. Each batch serves as a self-contained unit of production.

Controlled Atmosphere Integrity

Many advanced processes require a specific atmosphere, such as an inert gas, to prevent oxidation. In a batch system, the furnace is sealed with the material and the desired gas.

The rotary action ensures the entire material load interacts thoroughly and evenly with this controlled atmosphere, a level of integrity that can be more challenging to maintain in a continuous-feed system.

Understanding the Trade-offs: Batch vs. Continuous

Choosing between batch and continuous operation involves a fundamental trade-off between precision and throughput. Understanding this is key to selecting the right process for your goal.

Throughput and Scalability

The most significant drawback of batch processing is lower overall throughput. The process involves distinct cycles of loading, heating, cooling, and unloading, which introduces non-productive time.

A continuous rotary furnace, by contrast, is designed for high-volume production, processing a constant stream of material with minimal downtime.

Operational Flexibility

Batch operation is inherently more flexible. It is cost-effective for low-to-medium volume production and ideal for facilities that handle a high mix of different products or frequent changes in processing requirements.

Continuous systems excel at producing a single product at a massive scale but are less adaptable to frequent changes.

Making the Right Choice for Your Goal

The decision to leverage the batch capabilities of a rotary furnace should be driven by your primary operational objective.

- If your primary focus is process precision and quality: The combination of rotary mixing and batch control provides unparalleled uniformity and repeatability for complex heat treatments.

- If your primary focus is flexibility and research: The ability to run small, customized, and highly controlled batches makes this mode ideal for R&D, pilot-scale testing, and specialty manufacturing.

- If your primary focus is maximizing output: A continuous rotary furnace is the more efficient choice for high-volume, standardized production where throughput is the dominant metric.

Ultimately, using a rotary furnace in batch mode is a deliberate choice for precision and control over sheer volume.

Summary Table:

| Benefit | Description |

|---|---|

| Process Uniformity | Ensures even heating and mixing for consistent results |

| Precision Control | Allows customized recipes and repeatable cycles |

| Material Management | Simplifies tracking and accounting per batch |

| Atmosphere Integrity | Maintains controlled environments effectively |

| Operational Flexibility | Ideal for R&D and varied production needs |

Unlock Precision in Your Heat Treatment Processes with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you're in R&D, pilot-scale testing, or specialty manufacturing, our batch rotary furnaces deliver unmatched uniformity and control. Contact us today to discuss how we can tailor a solution for your specific needs and enhance your lab's efficiency!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing