In a dental laboratory, sintering is a critical heat treatment process that transforms a fragile, oversized restoration into its final, high-strength state. This process uses a specialized furnace to heat materials like zirconia, causing them to shrink, densify, and harden into a durable product capable of withstanding the forces of chewing.

Sintering is not merely heating; it is a precise, transformative process of densification and crystallization. It's the essential step that converts a soft, milled material into a strong, biocompatible, and clinically viable dental restoration.

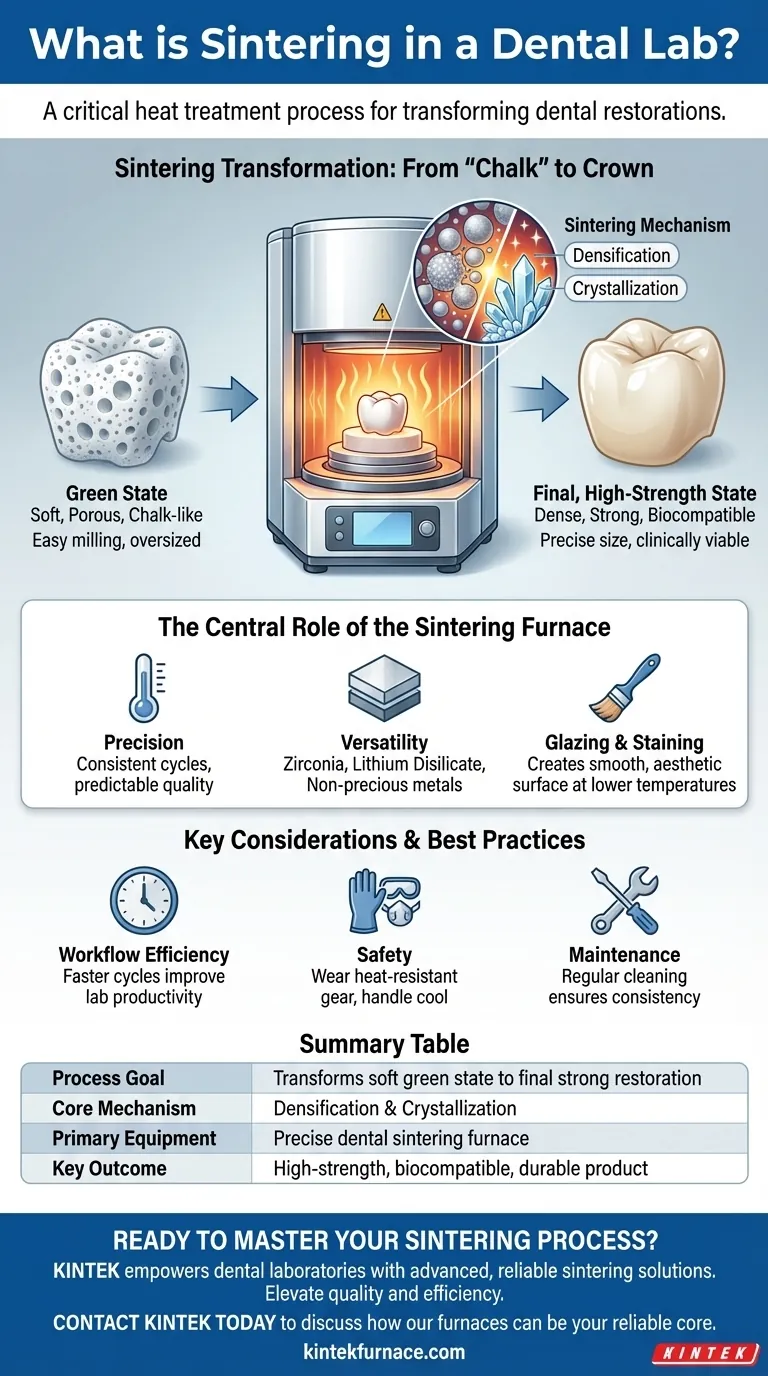

From "Chalk" to Crown: The Sintering Transformation

A restoration that comes out of a milling machine is not ready for a patient. Sintering is the bridge between the initial milled shape and the final, functional product.

The Initial "Green" State

After being milled, a material like zirconia exists in a soft, porous, and chalk-like state often called the "green state" or "pre-sintered state." This softness is intentional, as it allows for fast and precise machining with minimal wear on the milling tools.

The Sintering Mechanism

Inside the furnace, the restoration is subjected to extremely high temperatures for a specific period. During this cycle, the individual particles of the material fuse together, eliminating the microscopic voids between them. This is known as densification.

Simultaneously, the material undergoes crystallization, where its internal structure is rearranged into a stronger, more stable form. This dual process is what gives the final restoration its signature strength and durability.

The Final Outcome: Strength and Stability

The result of sintering is a restoration that has shrunk to its precise, intended size and has achieved its maximum density and strength. This final product is not only strong but also biocompatible, meaning it is safe for long-term use inside the patient's mouth.

The Central Role of the Sintering Furnace

The furnace is the core piece of equipment for this process, designed for much more than just generating heat.

A Tool for Precision

A dental sintering furnace is engineered to follow very specific heating and cooling cycles. This consistency is vital for ensuring that every crown, bridge, or implant framework achieves the exact same material properties, guaranteeing predictable and high-quality results.

Versatility in Materials and Use

While most commonly associated with zirconia, these furnaces are also used to process other advanced materials like lithium disilicate and some non-precious metals. They are instrumental in creating a wide range of restorations, including crowns, bridges, veneers, and implant components.

Beyond Sintering: Glazing and Staining

Many modern furnaces also perform secondary functions at lower temperatures. After sintering, a restoration is often customized with stains for color and then glazed to create a smooth, non-porous, and aesthetically pleasing surface. This final firing is often done in the same furnace.

Key Considerations and Best Practices

Executing the sintering process correctly is critical for lab productivity and the quality of the final product.

Impact on Workflow Efficiency

Sintering can be a lengthy process, sometimes taking several hours. A well-designed furnace that can handle multiple units or offers faster cycles can significantly improve a lab's workflow, productivity, and overall output.

The Non-Negotiable of Safety

Technicians must operate these high-temperature devices with care. Best practices include wearing heat-resistant gloves and goggles, following manufacturer instructions precisely, and allowing restorations to cool completely before handling to ensure both operator safety and material integrity.

Maintenance for Consistency

Regular cleaning and maintenance of the furnace are essential. Dust or debris accumulation can interfere with the heating elements and lead to inconsistent results, compromising the quality of the final restoration.

Making the Right Choice for Your Goal

Understanding sintering allows a lab to optimize its processes based on its primary objectives.

- If your primary focus is producing high-strength restorations: Sintering is the non-negotiable step that develops the necessary material properties for long-term clinical success.

- If your primary focus is superior aesthetics: The furnace is also your tool for the final glazing and staining cycles that create a lifelike and lustrous appearance.

- If your primary focus is lab productivity: Investing in a reliable, efficient furnace and adhering to strict maintenance and safety protocols is key to a smooth and predictable workflow.

Ultimately, mastering the sintering process is fundamental to a modern dental lab's ability to deliver durable, beautiful, and high-quality restorations.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process Goal | Transforms soft, milled "green state" zirconia into a dense, strong, final-sized restoration. |

| Core Mechanism | Densification (particles fuse, eliminating pores) and Crystallization (internal structure strengthens). |

| Primary Equipment | A specialized dental sintering furnace that provides precise temperature control and cycles. |

| Key Outcome | Creates a high-strength, biocompatible product capable of withstanding chewing forces. |

| Additional Functions | Many furnaces also handle final glazing and staining for aesthetics. |

Ready to Master Your Sintering Process?

Precision sintering is the foundation of durable and aesthetically perfect dental restorations. The right furnace is critical to your lab's success, productivity, and reputation.

KINTEK empowers dental laboratories like yours by providing advanced, reliable sintering solutions. Leveraging our exceptional R&D and in-house manufacturing, we offer a range of high-temperature furnaces known for their precision and durability. Our strong deep customization capability ensures your equipment precisely meets your unique workflow and material requirements.

Elevate the quality and efficiency of your crown, bridge, and implant production.

Contact KINTERO today to discuss how our sintering furnaces can become the reliable core of your dental lab.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations