At its core, a ceramic furnace is a specialized high-temperature oven engineered to process ceramic materials through precisely controlled heating and cooling cycles. It transforms raw, powdered, or milled ceramic into a hardened, durable final state with specific aesthetic and structural properties. This precision makes it an indispensable tool in fields like advanced dentistry, metallurgy, and laboratory research.

The defining characteristic of a ceramic furnace is not just its ability to reach high temperatures, but its capacity to execute a precise, multi-stage firing cycle. This controlled process is what gives the final ceramic product its required strength, density, and appearance.

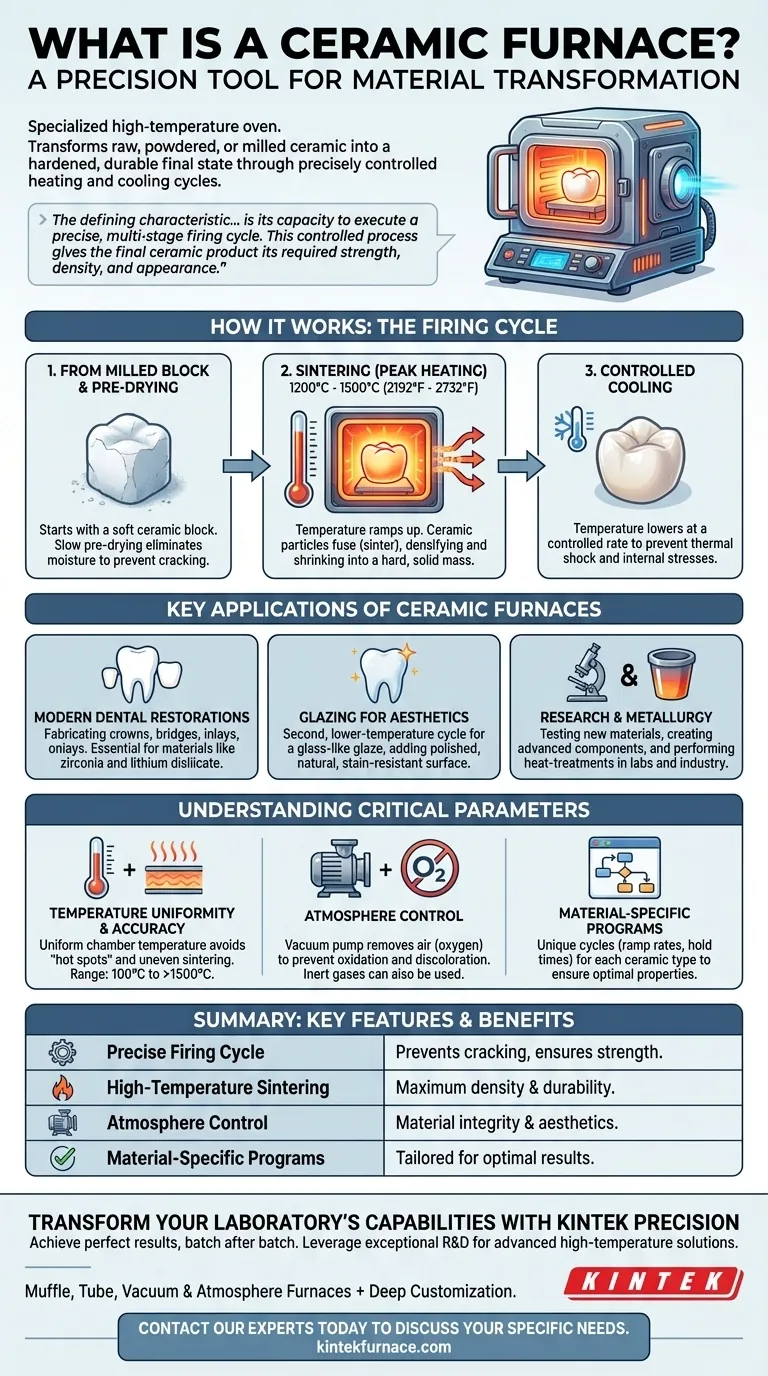

How a Ceramic Furnace Works: The Firing Cycle

A ceramic furnace does not simply heat an object. It executes a carefully programmed sequence of temperature changes, known as a firing cycle, to fundamentally alter the ceramic's internal structure.

From Milled Block to Final Restoration

The process often starts with a soft, chalk-like ceramic block that has been milled by a CAD/CAM system into the shape of a dental restoration, like a crown. The furnace’s job is to transition this fragile shape into its final, high-strength form.

Pre-Drying and Heating (Sintering)

The cycle begins with a slow pre-drying phase to eliminate any moisture, which prevents cracking. The temperature then ramps up significantly, often reaching between 1200°C and 1500°C (2192°F to 2732°F). During this peak heating stage, a process called sintering occurs, where the ceramic particles fuse together, causing the material to densify and shrink into a hard, solid mass.

Controlled Cooling

The cooling phase is just as critical as the heating phase. The furnace must lower the temperature at a controlled rate to prevent thermal shock, which could introduce internal stresses and cause the final product to fracture.

Key Applications of Ceramic Furnaces

While the term is broad, ceramic furnaces are most commonly associated with specific, high-value applications where material properties are paramount.

Modern Dental Restorations

This is the most prevalent use. Dentists and dental labs use these furnaces to fabricate crowns, bridges, inlays, and onlays. The furnace is essential for processing materials like zirconia and lithium disilicate after they have been milled.

Glazing for Aesthetics

After a dental restoration is sintered, it may undergo a second, lower-temperature cycle in the furnace. This is for applying a thin layer of glass-like glaze, which gives the restoration its natural, polished, and stain-resistant surface.

Research and Metallurgy

In laboratory and industrial settings, ceramic furnaces are used to test new materials, create advanced ceramic components, and perform heat-treatment processes in metallurgy. The furnace’s ability to maintain a precise, uniform temperature is critical for repeatable scientific experiments.

Understanding the Critical Parameters

The success or failure of the firing process hinges on precise control over several key variables. Mismanagement of these leads to weak, warped, or aesthetically poor results.

Temperature Uniformity and Accuracy

The temperature inside the furnace chamber must be extremely uniform. Any "hot spots" or "cold spots" will cause uneven sintering, leading to a warped and compromised final product. The temperature range varies by application, from 100°C to 1200°C for many dental ceramics up to over 1500°C for industrial uses.

Atmosphere Control

Many advanced furnaces use a vacuum pump to remove air from the chamber during the heating cycle. This is done to prevent oxygen from reacting with the ceramic materials, which could cause discoloration or compromise the material's integrity. The use of pressure or specific inert gases is another form of atmosphere control.

Material-Specific Programs

There is no universal firing cycle. Each type of ceramic material has a unique, manufacturer-specified program detailing the exact ramp rates, hold times, and peak temperatures required to achieve its intended properties. Using the wrong program will ruin the part.

Making the Right Choice for Your Goal

Selecting a furnace is about matching its capabilities to your specific application and materials.

- If your primary focus is clinical dental restorations: You need a furnace specifically designed for dental materials like zirconia, with reliable, pre-programmed cycles for sintering and glazing.

- If your primary focus is laboratory research: Prioritize a furnace with maximum temperature range, programmability, and atmosphere control to accommodate a wide variety of experimental materials.

- If your primary focus is high-volume dental lab production: Look for durability, automation features, and a large chamber to ensure consistent output and efficiency.

Ultimately, you are not just buying a heat source, but a precision instrument for material transformation.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Precise Firing Cycle | Executes multi-stage heating/cooling to prevent cracking and ensure material strength. |

| High-Temperature Sintering | Fuses ceramic particles at 1200°C-1500°C for maximum density and durability. |

| Atmosphere Control (Vacuum/Gas) | Prevents oxidation and discoloration, ensuring material integrity and aesthetics. |

| Material-Specific Programs | Tailored cycles for different ceramics (e.g., zirconia) guarantee optimal results. |

Transform Your Laboratory's Capabilities with KINTEK Precision

Are you fabricating high-strength dental restorations or conducting advanced materials research? The right ceramic furnace is not just an oven—it's the core of your quality and repeatability.

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental or production requirements.

Let us help you achieve perfect results, batch after batch.

Contact our experts today to discuss your specific needs

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations