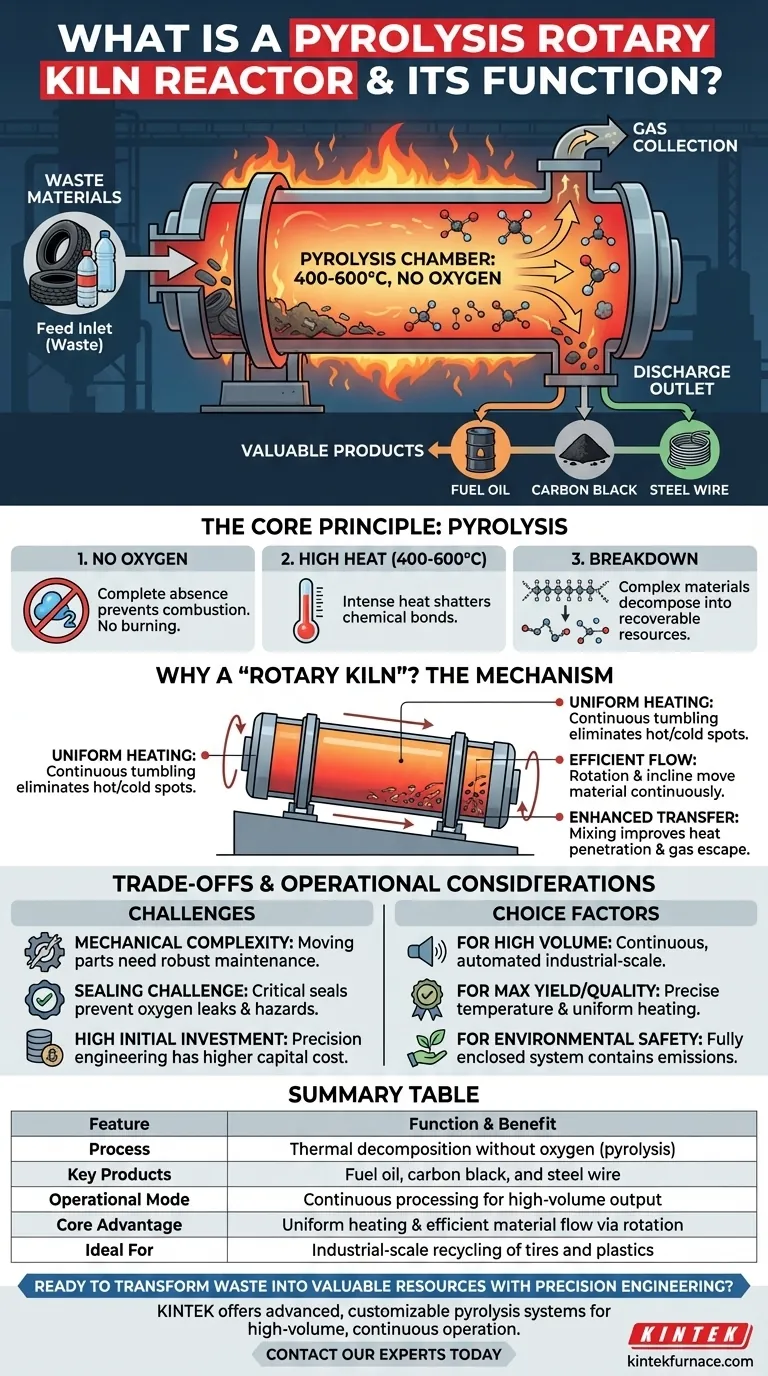

In essence, a pyrolysis rotary kiln reactor is a specialized industrial furnace designed to convert waste materials, such as old tires or plastics, into valuable products. It functions as the central chamber for pyrolysis—a process of high-temperature thermal decomposition that occurs in a completely oxygen-free environment. This controlled heating breaks down complex materials into fuel oil, carbon black, and steel wire without combustion.

A pyrolysis rotary kiln uses continuous rotation and precisely controlled heat within an oxygen-starved vessel to efficiently and uniformly break down waste materials, ensuring a complete chemical transformation into recoverable resources rather than simply burning them.

The Core Principle: How Pyrolysis Works

To understand the reactor, you must first understand the process it's built to facilitate. Pyrolysis is a specific type of thermochemical decomposition that differs fundamentally from burning.

Defining Pyrolysis

Pyrolysis is the act of heating a material to a very high temperature in the complete absence of oxygen. Because there is no oxygen, the material does not combust or catch fire. Instead, the intense heat breaks the chemical bonds within the material itself.

The Role of High Temperature

The reactor heats the material, typically waste tires or plastics, to temperatures between 400 and 600 degrees Celsius. This level of heat provides the energy needed to shatter long-chain polymer molecules into smaller, more valuable hydrocarbons.

The Critical Oxygen-Free Environment

This is the most important factor. By excluding oxygen, the reactor ensures the material decomposes into its constituent parts (gases, liquids, and solids) that can be collected. If oxygen were present, the material would simply burn, producing ash, smoke, and a fraction of the recoverable energy.

Why a "Rotary Kiln" is the Ideal Design

The design of the reactor is not arbitrary; the rotating, cylindrical shape is engineered to perfect the pyrolysis process. Its function is driven by three key mechanical advantages.

Ensuring Uniform Heating

The slow, continuous rotation of the kiln is crucial. It constantly tumbles the material, ensuring every part of it is evenly exposed to the heat source. This eliminates hot and cold spots, leading to a thorough and complete chemical breakdown and maximizing the yield of valuable products.

Facilitating Efficient Material Flow

The kiln is mounted on a slight incline. As it rotates, gravity and the tumbling motion automatically and continuously move the material from the feed inlet at the higher end to the discharge outlet at the lower end. This prevents blockages and allows for continuous operation.

Enhancing Heat and Mass Transfer

The mixing action caused by rotation significantly improves efficiency. It allows the volatile gases released during pyrolysis to escape from the solid material easily, and it ensures that heat can penetrate the entire batch quickly and evenly.

Understanding the Trade-offs

While highly effective, the rotary kiln design has specific operational considerations that are important to understand. Its advantages in efficiency come with inherent complexities.

Mechanical Complexity

Unlike a static reactor, a rotary kiln has numerous moving parts, including the drive system, support rollers, and bearings. These components are subject to wear and tear from continuous operation at high temperatures and require a robust preventative maintenance schedule.

The Sealing Challenge

Maintaining a perfectly sealed, oxygen-free environment inside a large, rotating vessel is a significant engineering challenge. The seals at the feed and discharge ends are critical points of failure and must be meticulously maintained to prevent oxygen leaks, which would compromise the pyrolysis process and create safety hazards.

High Initial Investment

The robust construction, precision engineering, and complex mechanical systems of a pyrolysis rotary kiln reactor typically result in a higher upfront capital cost compared to simpler, less efficient batch-style systems.

Making the Right Choice for Your Goal

The decision to use a pyrolysis rotary kiln reactor should be based on your operational priorities.

- If your primary focus is continuous, high-volume processing: The automated material flow and robust design make it the superior choice for industrial-scale waste conversion.

- If your primary focus is maximizing product yield and quality: The precise temperature control and uniform heating offered by this design ensure the most complete and consistent pyrolysis reaction.

- If your primary focus is environmental compliance and safety: The fully enclosed system provides the best method for containing and managing emissions, far surpassing open or less-controlled alternatives.

Ultimately, the pyrolysis rotary kiln reactor is a powerful tool that transforms a waste liability into a valuable resource.

Summary Table:

| Feature | Function & Benefit |

|---|---|

| Process | Thermal decomposition without oxygen (pyrolysis) |

| Key Products | Fuel oil, carbon black, and steel wire |

| Operational Mode | Continuous processing for high-volume output |

| Core Advantage | Uniform heating & efficient material flow via rotation |

| Ideal For | Industrial-scale recycling of tires and plastics |

Ready to transform waste into valuable resources with precision engineering?

Backed by expert R&D and manufacturing, KINTEK offers advanced, customizable pyrolysis systems, including robust rotary kiln reactors. Our solutions are designed for high-volume, continuous operation, ensuring maximum yield and efficiency for your specific needs.

Contact our experts today to discuss how we can help you achieve your waste conversion goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How do pyrolysis rotary kiln reactors function? Unlock Efficient Waste-to-Value Conversion

- What are the key components and parameters of a rotary kiln? Optimize Your High-Temperature Processing

- What is the working principle of a pyrolysis rotary kiln reactor? Efficient Waste-to-Energy Conversion

- What is the significance of rotation in a pyrolysis rotary kiln reactor? Unlock Efficient Waste-to-Energy Conversion

- How does a rotary furnace compare to a fixed-bed furnace for powder? Optimize Uniformity in Large-Scale Production