The primary function of a muffle furnace in this process is to provide a controlled, oxygen-rich thermal environment essential for converting precursors into metal-doped cobalt spinel oxide (CSO). By executing a specific heating program under an air atmosphere, the furnace facilitates the chemical reactions necessary to transform the starting material into its final crystalline form.

The muffle furnace drives the synthesis by maintaining a consistent temperature in the presence of air, triggering the simultaneous pyrolysis and oxidation of the metal-organic framework (MOF). This controlled thermal treatment collapses the precursor structure to create stable, metal-doped cobalt spinel oxide.

The Mechanics of Material Conversion

Facilitating Pyrolysis and Oxidation

The core role of the muffle furnace is to initiate high-temperature chemical reactions. Specifically, it triggers pyrolysis and oxidation within the precursor material.

Because the furnace operates under an air atmosphere, oxygen is available to react with the precursor. This is distinct from inert environments used in other furnace types, making the muffle furnace the specific tool of choice for creating oxides.

Structural Collapse and Crystallization

The precursor material in this process is a metal-doped Metal-Organic Framework (MOF). The thermal energy provided by the furnace causes this MOF structure to collapse.

As the organic components break down, the remaining metal ions rearrange. This results in a phase transformation, creating the specific crystalline structure of metal-doped cobalt spinel oxide (CSO).

Critical Operational Parameters

Precision Temperature Control

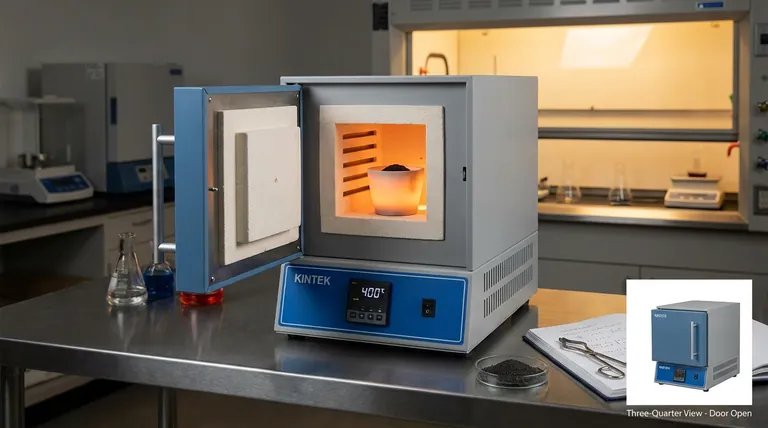

Success depends on adhering to a strict heating profile. The muffle furnace is programmed to reach and maintain a specific target, typically 400 degrees Celsius.

Duration of Treatment

Time is as critical as temperature. The material is held at this heat level for a set duration, such as 4 hours. This ensures the reaction is complete throughout the bulk of the material, preventing uniformities in the final oxide.

Understanding the Constraints

Atmosphere Limitations

It is important to recognize that a muffle furnace in this context is generally an open-air system.

While ideal for oxidation (creating CSO), it is ill-suited for processes requiring inert atmospheres, such as carbonization or preventing oxidation. If your goal were to process materials under argon to create sulfides (like MoS2), a tube furnace would be the required tool, not a muffle furnace.

Thermal Uniformity

While effective for batch processing, muffle furnaces can sometimes exhibit thermal gradients. Ensuring the sample is positioned centrally is vital to guarantee that the specific 400°C target is met evenly across the entire sample mass.

Making the Right Choice for Your Goal

To ensure high-quality synthesis of cobalt spinel oxide, consider the following parameters:

- If your primary focus is Phase Purity: Ensure the furnace is calibrated to hold exactly 400°C; deviations can lead to incomplete MOF collapse or unwanted impurities.

- If your primary focus is Complete Oxidation: Verify that the furnace vents allow sufficient air exchange, as oxygen is a reagent in converting the MOF to CSO.

The muffle furnace is the definitive tool for this synthesis because it couples precise heat with the oxidative atmosphere required to crystallize the final oxide structure.

Summary Table:

| Feature | Role in CSO Synthesis | Importance |

|---|---|---|

| Atmosphere | Open-air / Oxygen-rich | Essential for simultaneous pyrolysis and oxidation |

| Temperature | Stable 400°C Control | Ensures complete MOF structural collapse |

| Dwell Time | 4-Hour Hold | Guarantees phase purity and crystalline uniformity |

| Reaction Type | Phase Transformation | Converts metal-organic precursors into stable spinel oxides |

Elevate Your Material Synthesis with KINTEK Precision

Unlock superior results in your oxide crystallization and MOF conversions. KINTEK provides high-performance heating solutions—including Muffle, Tube, Rotary, and Vacuum systems—engineered for the rigorous demands of modern laboratories.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet your specific temperature and atmospheric requirements. Whether you are developing metal-doped cobalt spinel oxides or advanced CVD materials, KINTEK delivers the thermal precision your research deserves.

Ready to optimize your high-temperature processes? Contact our technical experts today to discuss your unique needs and find the perfect furnace for your lab.

References

- Kangjae Lee, Taeghwan Hyeon. Tailoring cobalt spinel oxide with site-specific single atom incorporation for high-performance electrocatalysis. DOI: 10.1039/d4ee00058g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What safety measures should be followed when using a muffle furnace? Essential Steps for Safe Operation

- What is the role of a high-temperature muffle furnace in treating Mn3O4 nanowires? Optimize Phase Stability

- What maintenance checks are required for a muffle furnace? Ensure Safety and Accuracy in Your Lab

- What role does a box muffle furnace play in life sciences? Unlock Precise Mineral Analysis in Research

- What are the advantages of the bottom-loading furnace configuration? Achieve High-Temp Control and Element Protection

- What is the function of a muffle furnace during Cu–Ce/HZSM-5 production? Optimize Calcination & Regeneration Stages

- What role does an industrial High-temperature Electric Furnace play? Achieve Precise Carbon Steel Standardization

- What personal protective equipment (PPE) should be worn when operating a muffle furnace? Ensure Complete Lab Safety