At its core, a bottom-loading furnace offers a distinct advantage over standard designs: the ability to achieve higher operating temperatures by physically isolating its heating elements from the process atmosphere. This configuration uses a removable, sealed dome to create a controlled environment around the sample, protecting the external elements and enabling temperatures that can exceed 1700°C.

The key benefit of a bottom-loading furnace isn't just about reaching high heat; it's about enabling high-temperature processing with controlled atmospheres that would be corrosive or damaging to the heating elements in a conventional furnace design.

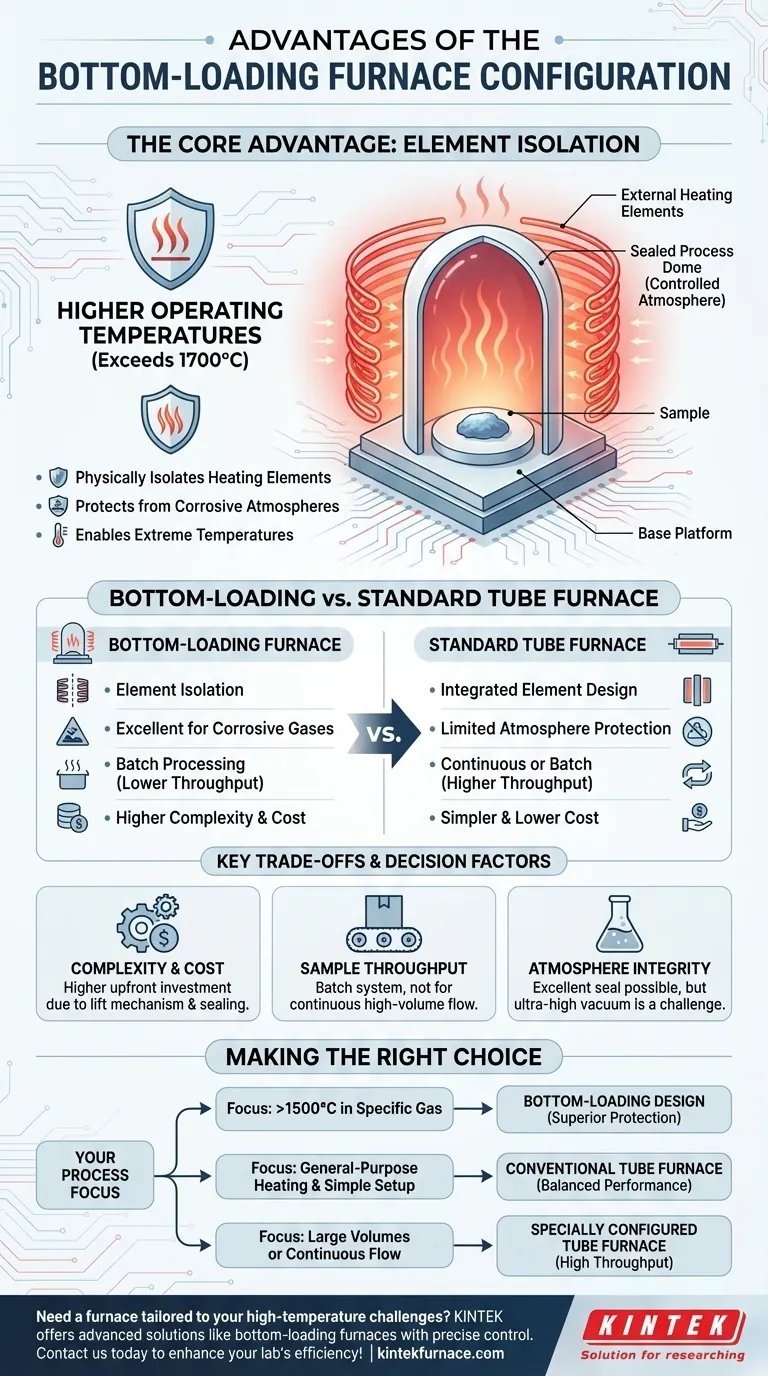

The Core Design Advantage: Element Isolation

The primary benefits of a bottom-loading furnace stem directly from its unique physical architecture, which separates the heating source from the process environment.

How the Design Works

A bottom-loading furnace typically consists of a base platform where the sample is placed. An inverted ceramic dome or tube is then lowered over the sample, sealing against a floor plate.

This sealed dome contains the inlet and outlet ports needed to introduce specific gases or create a vacuum, establishing a controlled process atmosphere.

Protecting the Heating Elements

The heating elements are located outside this sealed atmosphere dome. They heat the dome, which in turn radiates heat uniformly onto the sample inside.

Because the elements are only exposed to the ambient air, they are completely protected from any reactive, corrosive, or contaminating gases used in the process.

Enabling Higher Temperatures and Exotic Atmospheres

This element protection is what allows the furnace to achieve extreme temperatures, often up to 1700°C or higher.

Standard furnace elements would quickly degrade or fail at these temperatures if exposed to many process atmospheres. Isolation makes these demanding applications possible.

Contrasting with Standard Tube Furnaces

To fully appreciate the bottom-loading design, it's helpful to compare it to the more common horizontal or vertical tube furnace.

Integrated Element Design

In a standard tube furnace, the heating elements are wrapped directly around the ceramic process tube that contains the sample and the atmosphere.

The elements are separated from the process gas only by the thickness of the tube wall. Any permeation or reaction with the tube material at high temperatures can affect element life.

The Benefit of Simplicity and Cost

Tube furnaces are a mature, simple, and often inexpensive technology. Their straightforward design makes them easy to operate and control for a wide range of applications.

This simplicity and wide availability make them the default choice for many labs and industrial processes.

Excellent Temperature Uniformity

A key advantage of the tube furnace design is its ability to create a very uniform temperature zone along the central length of the tube. This is ideal for processes requiring consistent heat over a specific area.

Understanding the Trade-offs

Choosing a bottom-loading furnace involves considering its specific advantages against its inherent complexities. It is not the right tool for every job.

Mechanical Complexity and Cost

The mechanism required to lift, lower, and seal the atmosphere dome makes a bottom-loading furnace mechanically more complex and generally more expensive than a standard tube furnace of a similar size.

Sample Throughput

A bottom-loading furnace is fundamentally a batch processing system. Each run requires loading the sample, sealing the chamber, running the process, cooling down, and unloading.

In contrast, some tube furnaces can be configured for continuous production, where material is constantly fed through the hot zone, allowing for much higher throughput.

Atmosphere Integrity

While the dome provides a good seal, achieving the ultra-high vacuum or extreme atmospheric purity possible in a fully sealed, monolithic tube furnace can be a greater engineering challenge. The quality of the dome's seal is a critical design factor.

Making the Right Choice for Your Process

Your decision should be guided by the specific temperature, atmosphere, and throughput requirements of your work.

- If your primary focus is achieving temperatures above 1500°C in a specific gas environment: The bottom-loading design is superior, as it protects the heating elements from degradation and enables these extreme conditions.

- If your primary focus is general-purpose heating with a simple setup: A conventional tube furnace often provides the best balance of performance, uniform heating, and cost-effectiveness.

- If your primary focus is processing large volumes or continuous material flow: A specially configured tube furnace is designed for this workflow, whereas a bottom-loading furnace is a batch-based system.

Ultimately, selecting the right furnace requires matching the unique capabilities of its design to the specific demands of your application.

Summary Table:

| Feature | Bottom-Loading Furnace | Standard Tube Furnace |

|---|---|---|

| Max Temperature | Exceeds 1700°C | Typically lower, depends on design |

| Atmosphere Control | Excellent for corrosive gases, protects elements | Limited by element exposure |

| Temperature Uniformity | Good, via radiant heating | Excellent along tube length |

| Sample Throughput | Batch processing | Can be continuous or batch |

| Cost | Higher due to complexity | Lower, more cost-effective |

| Ideal Use Cases | High-temp processes with reactive atmospheres | General-purpose heating, high throughput |

Need a furnace tailored to your high-temperature challenges? KINTEK specializes in advanced solutions like bottom-loading furnaces, offering precise temperature control and robust element protection for demanding environments. With our deep customization capabilities and full in-house manufacturing, we deliver Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems to meet your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are some specific applications of atmosphere furnaces in the ceramics industry? Enhance Purity and Performance

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing