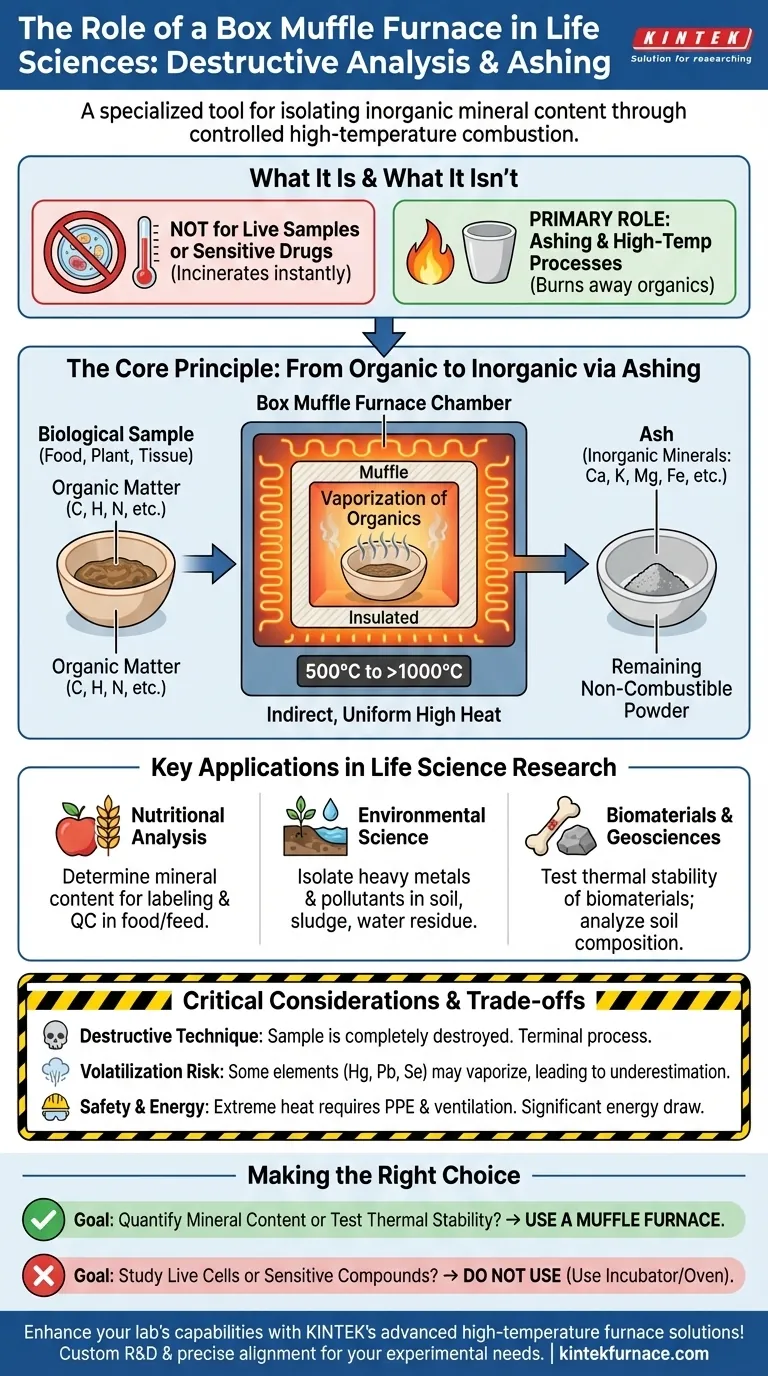

In life sciences, a box muffle furnace serves a very specific and destructive analytical purpose. It is not used for cultivating live samples like cell cultures or testing sensitive drugs, as its extreme temperatures would incinerate them instantly. Instead, its primary role is to perform high-temperature processes like ashing, where it burns away all organic material from a sample to isolate and quantify the remaining inorganic components, such as minerals.

A muffle furnace is an analytical tool used to transform a biological sample into ash. By removing the organic matter, researchers can accurately measure the mineral content, which is a critical step in nutritional science, environmental analysis, and biomaterials research.

The Core Principle: From Organic to Inorganic

A muffle furnace operates on a simple yet powerful principle: using controlled, high-temperature heat to break down complex organic matter into its fundamental inorganic constituents.

What is a "Muffle"?

The term "muffle" refers to the furnace's insulated inner chamber, which separates the sample from the heating elements (like resistance wires). This design ensures the sample is heated uniformly by the surrounding hot air, not by direct contact with flames or electrical components. This indirect heating method provides precise temperature control, which is essential for repeatable scientific results.

The Process of Ashing

Ashing is the most common use for a muffle furnace in life sciences. A biological sample—such as food, plant tissue, or animal feed—is placed in a crucible and heated to temperatures typically ranging from 500°C to over 1000°C. At this heat, all organic compounds (carbon, hydrogen, nitrogen, etc.) are completely burned off and vaporized.

Why This Matters for Analysis

What remains after ashing is a small amount of non-combustible powder: the ash. This ash contains the sample's entire mineral content, including essential elements like calcium, potassium, magnesium, and iron. By weighing the sample before and after ashing, researchers can determine the total ash content, providing a crucial data point for further analysis.

Key Applications in Life Science Research

The ability to isolate inorganic content makes the muffle furnace indispensable in several fields.

Nutritional Analysis

In food science and nutrition, muffle furnaces are used to determine the mineral content of foods and animal feeds. This process is fundamental for accurate nutritional labeling, quality control, and ensuring products meet regulatory standards for essential minerals.

Environmental Science

Researchers use muffle furnaces to prepare soil, sludge, or water residue samples for analysis. Ashing the samples helps isolate heavy metals and other inorganic pollutants, allowing for precise measurement of environmental contamination.

Biomaterials and Geosciences

When developing heat-resistant biomaterials, such as ceramic-based bone grafts, a muffle furnace helps test thermal stability and composition. In geology and soil science, it helps determine the organic versus mineral content of a given sample.

Understanding the Trade-offs and Considerations

While powerful, a muffle furnace is a specialized tool with important limitations.

It is a Destructive Technique

The most critical point to understand is that ashing is a terminal process. The sample is completely destroyed. Therefore, a muffle furnace is an analytical tool for composition, not a preparatory tool for cultivating or studying live biological systems. Any suggestion of its use for cell culture is incorrect and dangerous.

Risk of Volatilization

Certain inorganic elements, such as mercury, lead, and selenium, can vaporize at the high temperatures used for ashing. This process, known as volatilization, can lead to an underestimation of their presence in the sample. Specialized procedures are required to analyze these volatile minerals accurately.

Safety and Energy Consumption

Operating at extreme temperatures, muffle furnaces require strict safety protocols, including proper ventilation to handle fumes and the use of personal protective equipment. Their insulated chambers are designed for energy efficiency, but they still represent a significant energy draw in the lab.

Making the Right Choice for Your Goal

Deciding whether to use a muffle furnace depends entirely on what you need to measure.

- If your primary focus is quantifying mineral content in food, soil, or tissue: A muffle furnace is the standard and essential tool for preparing these samples via ashing.

- If your primary focus is studying live cells or thermally sensitive compounds: A muffle furnace is entirely inappropriate; you need a CO2 incubator, a low-temperature oven, or a water bath.

- If your primary focus is analyzing the thermal stability of new biomaterials: The furnace is an excellent tool for subjecting materials to extreme heat in a controlled environment.

Ultimately, a muffle furnace empowers researchers to look past the organic complexity of a sample and reveal its essential mineral foundation.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | Ashing to isolate inorganic minerals from organic samples |

| Temperature Range | 500°C to over 1000°C |

| Key Applications | Nutritional analysis, environmental science, biomaterials research |

| Sample Types | Food, plant tissue, animal feed, soil, sludge |

| Limitations | Destructive technique, not for live samples; risk of volatilization for certain elements |

Enhance your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Our expertise in R&D and in-house manufacturing allows us to provide tailored equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Whether you're in nutritional science, environmental analysis, or biomaterials development, our deep customization ensures precise alignment with your unique experimental needs. Contact us today to discuss how we can support your research goals and deliver reliable, efficient furnace solutions!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide