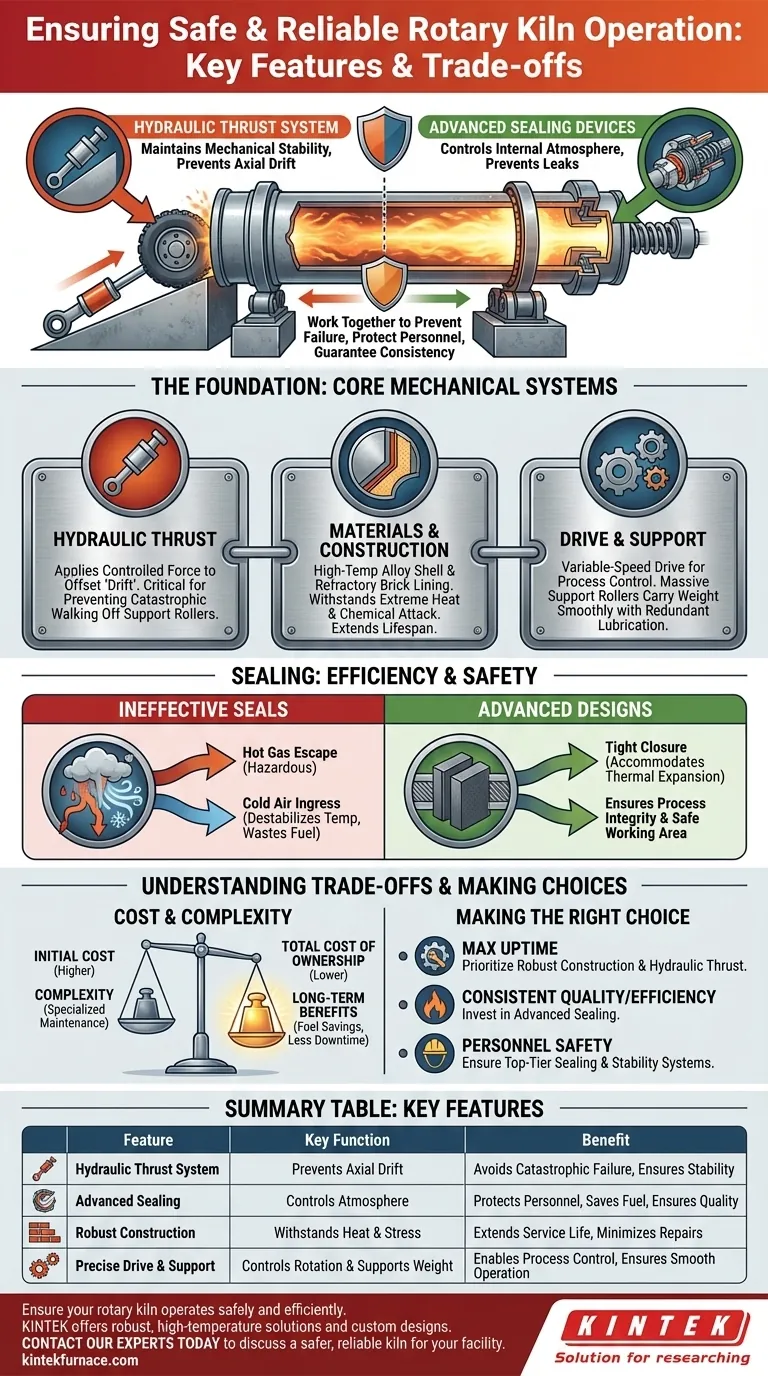

At its core, the safe and reliable operation of a rotary kiln is ensured by two primary engineering features: hydraulic pushing mechanisms to maintain mechanical stability and advanced sealing devices to control the internal atmosphere. These systems work together to prevent catastrophic failure, protect personnel, and guarantee the consistency of the thermal process.

A rotary kiln's reliability is not just about avoiding accidents; it is fundamentally about maintaining the precise, high-temperature environment required for consistent product quality. The key safety features are therefore integral to both operational security and process efficiency.

The Foundation of Reliability: Core Mechanical Systems

A rotary kiln is a massive, dynamic piece of equipment. Its reliability hinges on the systems that control its movement and withstand immense thermal and mechanical stress.

The Hydraulic Thrust System

The kiln rotates on a slight incline, causing it to naturally "drift" downhill. A hydraulic pushing mechanism, or thrust roller, applies controlled force to the kiln's tires, preventing this axial movement. This is critical for preventing the kiln from walking off its support rollers, which would be a catastrophic failure.

High-Quality Materials and Construction

A kiln's service life is directly tied to the quality of its materials. The shell is built from steel alloys designed to resist high temperatures and distortion, while the interior is lined with refractory bricks that can withstand extreme heat and chemical attack from the processed material. This robust construction minimizes the need for frequent repairs and extends the equipment's operational lifespan.

The Main Drive and Support System

Reliability also depends on the kiln's drive system and support rollers (trunnions). A variable-speed drive allows for precise control over material retention time. The massive support rollers and tires are engineered to carry the kiln's immense weight smoothly, with redundant lubrication systems often in place to prevent bearing failure.

Sealing: The Key to Efficiency and Safety

The seals at the feed and discharge ends of the kiln are among its most critical components. Their performance directly impacts safety, product quality, and fuel consumption.

Why Sealing is Critical

Ineffective seals create two major problems. First, they allow hot, dusty gas to escape, creating a hazardous environment for personnel. Second, they allow cold ambient air to leak into the kiln, which destabilizes the internal temperature, wastes enormous amounts of fuel, and can ruin the final product.

Advanced Sealing Devices

Modern kilns move beyond simple seals, using advanced designs like spring-loaded graphite block seals or labyrinth seals. These systems are designed to accommodate the thermal expansion and contraction of the kiln shell while maintaining a tight closure, ensuring both process integrity and a safe working area.

Understanding the Trade-offs

Investing in advanced safety and reliability features requires a clear understanding of the costs and benefits.

Initial Cost vs. Total Cost of Ownership

Kilns equipped with advanced hydraulic systems and high-performance seals have a higher initial purchase price. However, this upfront investment is often recovered through lower fuel consumption, reduced unplanned downtime, and a significantly longer service life, resulting in a lower total cost of ownership.

Complexity and Maintenance

While more reliable, advanced systems can introduce complexity. A sophisticated hydraulic thrust system or a high-tech seal may require specialized training or technicians for proper maintenance and repair. This is a critical factor to consider when planning operational support.

Making the Right Choice for Your Operation

The emphasis you place on specific features should align directly with your primary operational goals.

- If your primary focus is maximum uptime and longevity: Prioritize kilns with robust construction, high-quality refractory linings, and a proven hydraulic thrust system.

- If your primary focus is consistent product quality and fuel efficiency: Invest in the most advanced sealing technology available to maintain absolute control over the kiln's internal atmosphere.

- If your primary focus is personnel safety: Ensure that both the sealing system (to contain hot gas and dust) and the mechanical stability systems are top-tier, with no compromises.

Ultimately, viewing these features not as expenses but as investments in operational integrity is the key to long-term success.

Summary Table:

| Safety & Reliability Feature | Key Function | Benefit |

|---|---|---|

| Hydraulic Thrust System | Prevents axial drift of the kiln | Avoids catastrophic failure, ensures mechanical stability |

| Advanced Sealing Devices | Controls internal atmosphere, prevents leaks | Protects personnel, saves fuel, ensures product quality |

| Robust Construction & Refractory | Withstands extreme heat and stress | Extends service life, minimizes repairs |

| Precise Drive & Support System | Controls rotation and supports weight | Enables process control, ensures smooth operation |

Ensure your rotary kiln operates safely and efficiently for years to come. The right design is critical for preventing downtime, protecting your team, and guaranteeing product quality. Backed by expert R&D and manufacturing, KINTEK offers robust, high-temperature processing solutions, including custom rotary kilns designed for your unique operational needs. Contact our experts today to discuss how we can build a safer, more reliable kiln for your facility.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits